Method for reducing emissions from evaporative emissions control systems

a technology of evaporative emissions control and emission reduction, which is applied in the direction of combustion-air/fuel-air treatment, other chemical processes, separation processes, etc., can solve the problems of unacceptably high flow restriction of small particles, hinder the diffusional transport of vapors, and hydrocarbon air pollution, etc., to reduce diurnal breathing loss emissions, reduce emissions canisters, and reduce the effect of incremental capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

)

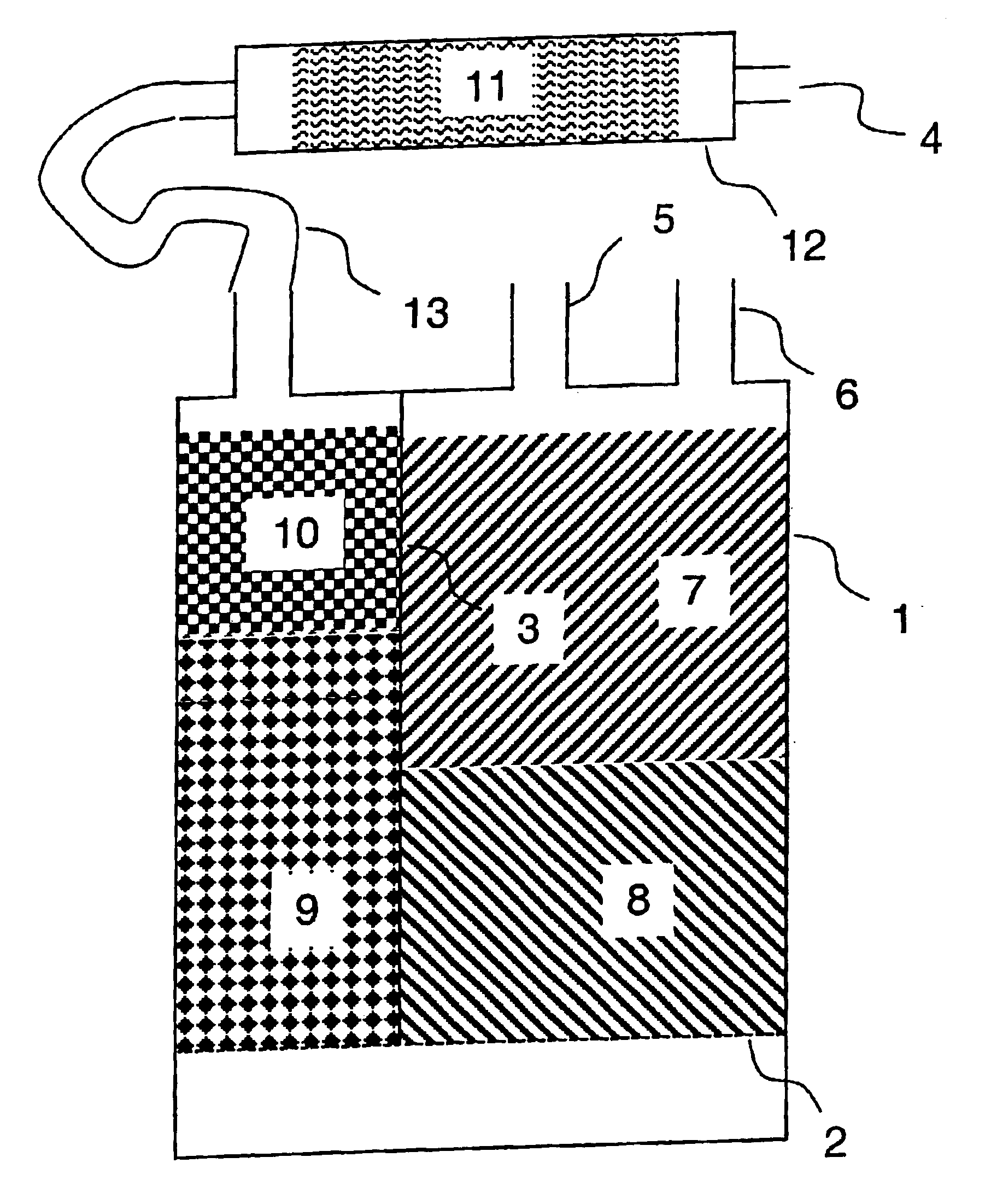

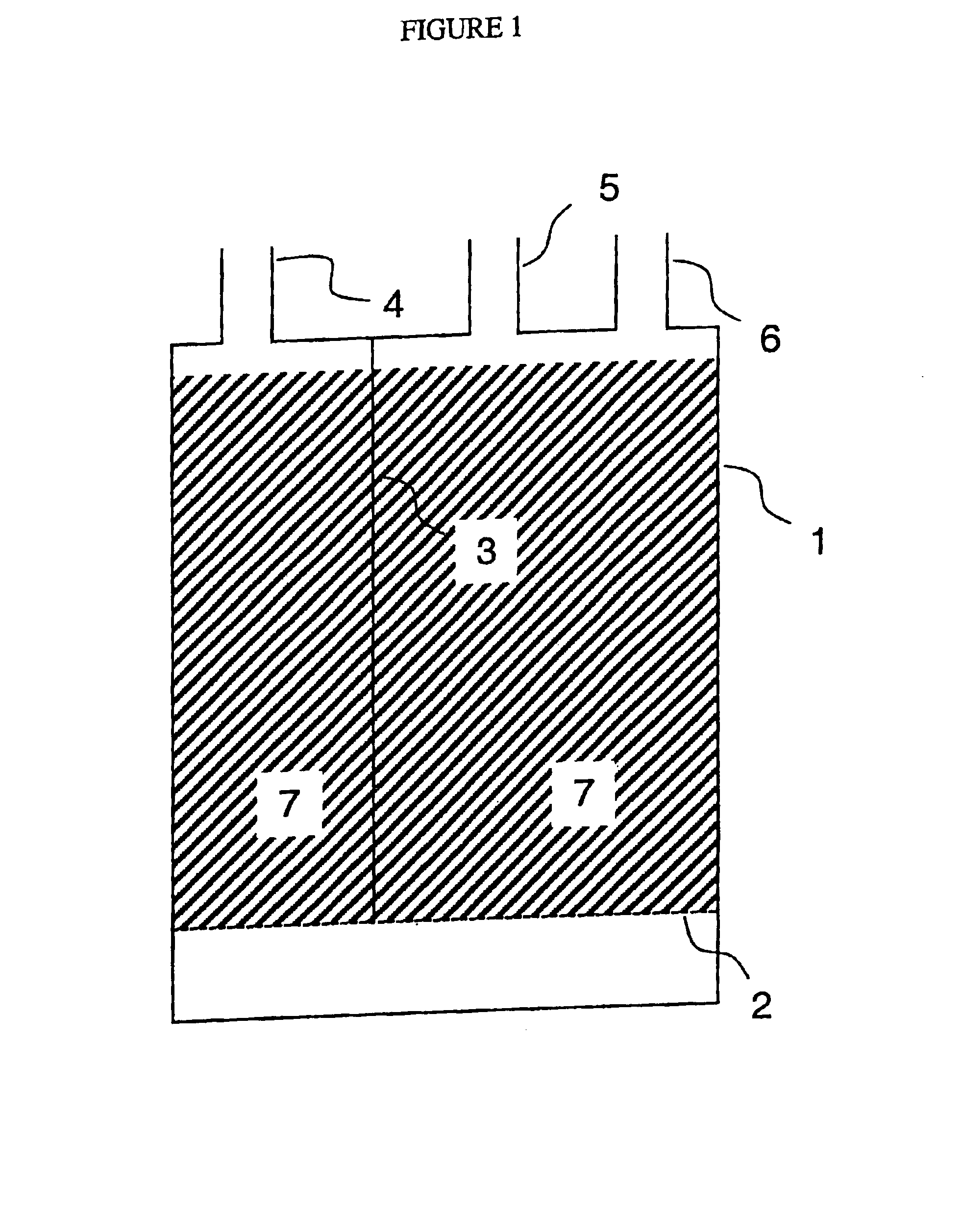

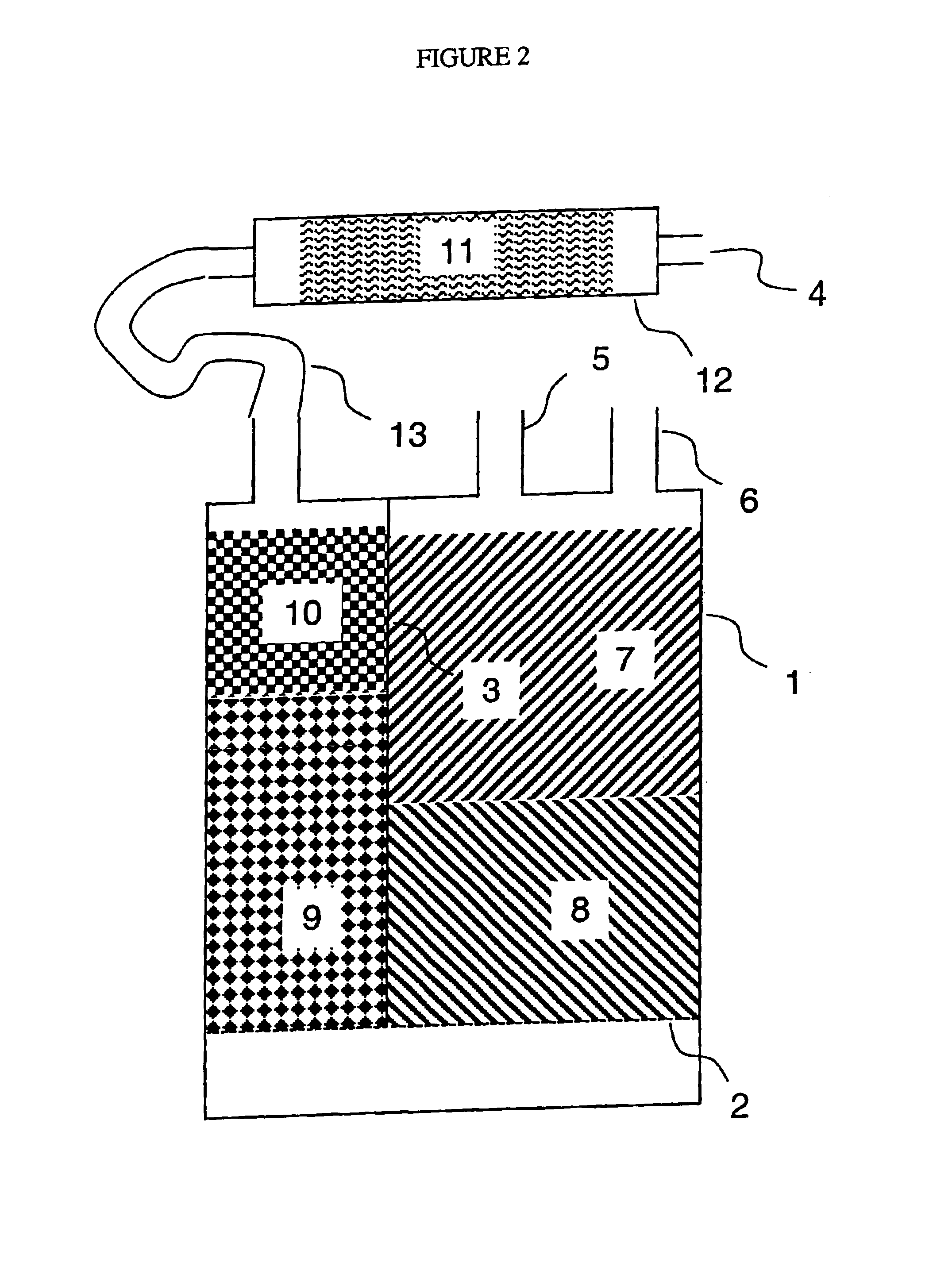

[0020]The disclosed invention relates to the use of multiple beds (or layers, stages, or chambers) of adsorbent materials, which, in combination, significantly reduce DBL emissions while maintaining the high working capacity and low flow restriction properties of the canister system. (See FIG. 2.) These adsorbents include activated carbon from a variety of raw materials, including wood, peat, coal, coconut, synthetic or natural polymer, and a variety of processes, including chemical and / or thermal activation, as well as inorganic adsorbents, including molecular sieves, porous alumina, pillared clays, zeolites, and porous silica, and organic adsorbents, including porous polymers. The adsorbents may be in granular, spherical, or pelletized cylindrical shapes, or may be extruded into special thin-walled cross-sectional shapes, such as hollow-cylinder, star, twisted spiral, asterisk, configured ribbons, or other shapes within the technical capabilities of the art. In shaping, inorganic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| concentrations | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com