Method and device for training the tactile perception of a marksman, in particular a sport marksman

a technology for a marksman and a training method, applied in the field of sports marksman, to achieve the effect of efficiently assisting in mastering the sho

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

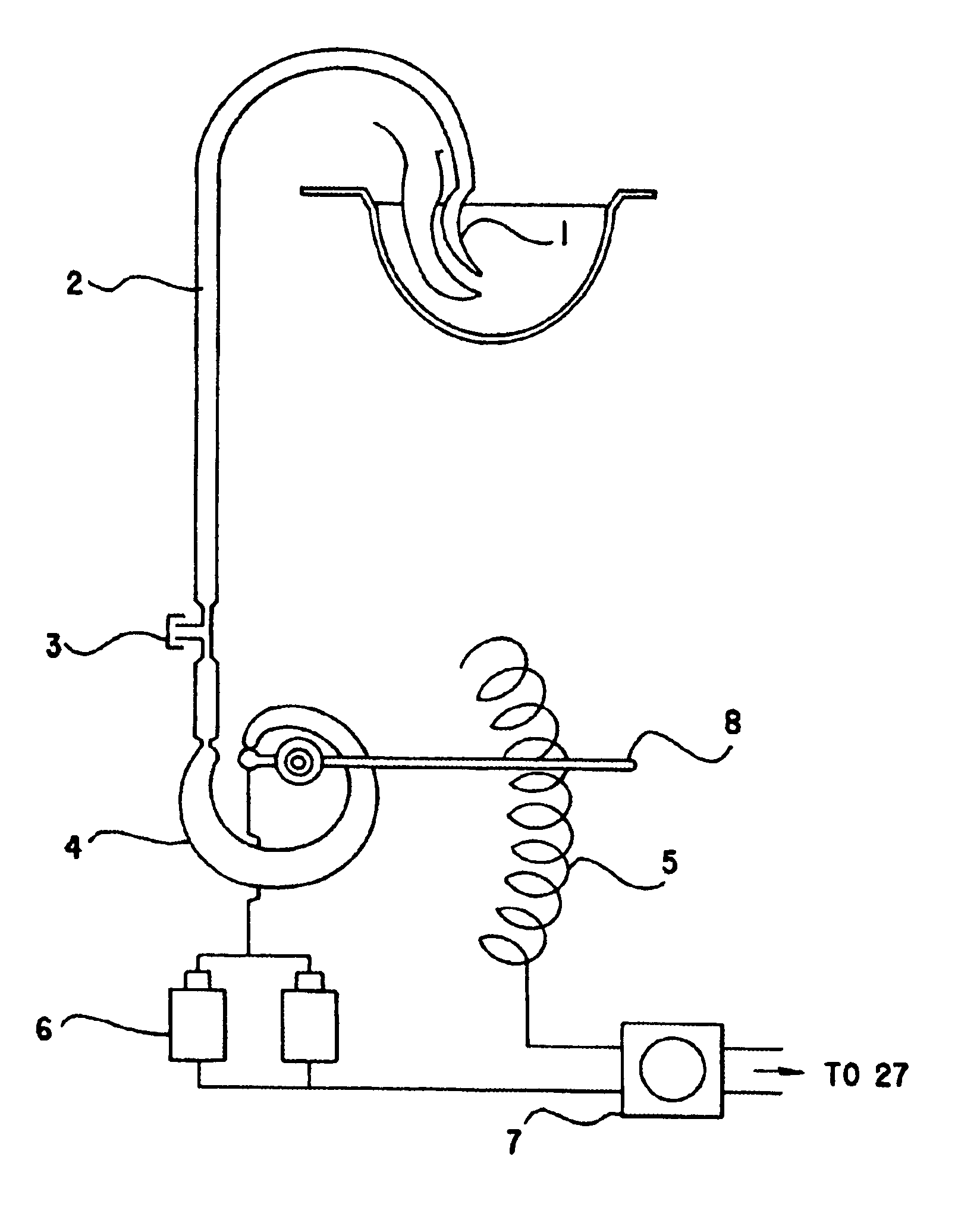

[0032]We are now going to describe a device for implementing the invention, in reference to FIG. 1.

[0033]According to this embodiment, the conversion of the pressure exercised on the trigger 11 of any firearm (not represented) into electric signals is realized by a hydraulic system.

[0034]An elastic pressure-receiving capsule 1 is glued on a glove finger placed over the marksman's forefinger (not represented) or fixed to the trigger 11. The liquid-filled capsule is submitted to the pressure exercised by the marksman. A fine, ductile but not elastic tube 2 transmits this pressure, thanks to the liquid, to a manometer 4 which, by the deformation of its flattened tube, acts on the cursor hand 8 of a rheostat 5. In a classical manner there is a purge 3. An electric current source 6 (a cell or rechargeable battery can be used here as well) feeds a serial circuit comprising the rheostat 5 and a receiver organ 7, including an entry resistance. Depending on the pressure exercised by the mark...

second embodiment

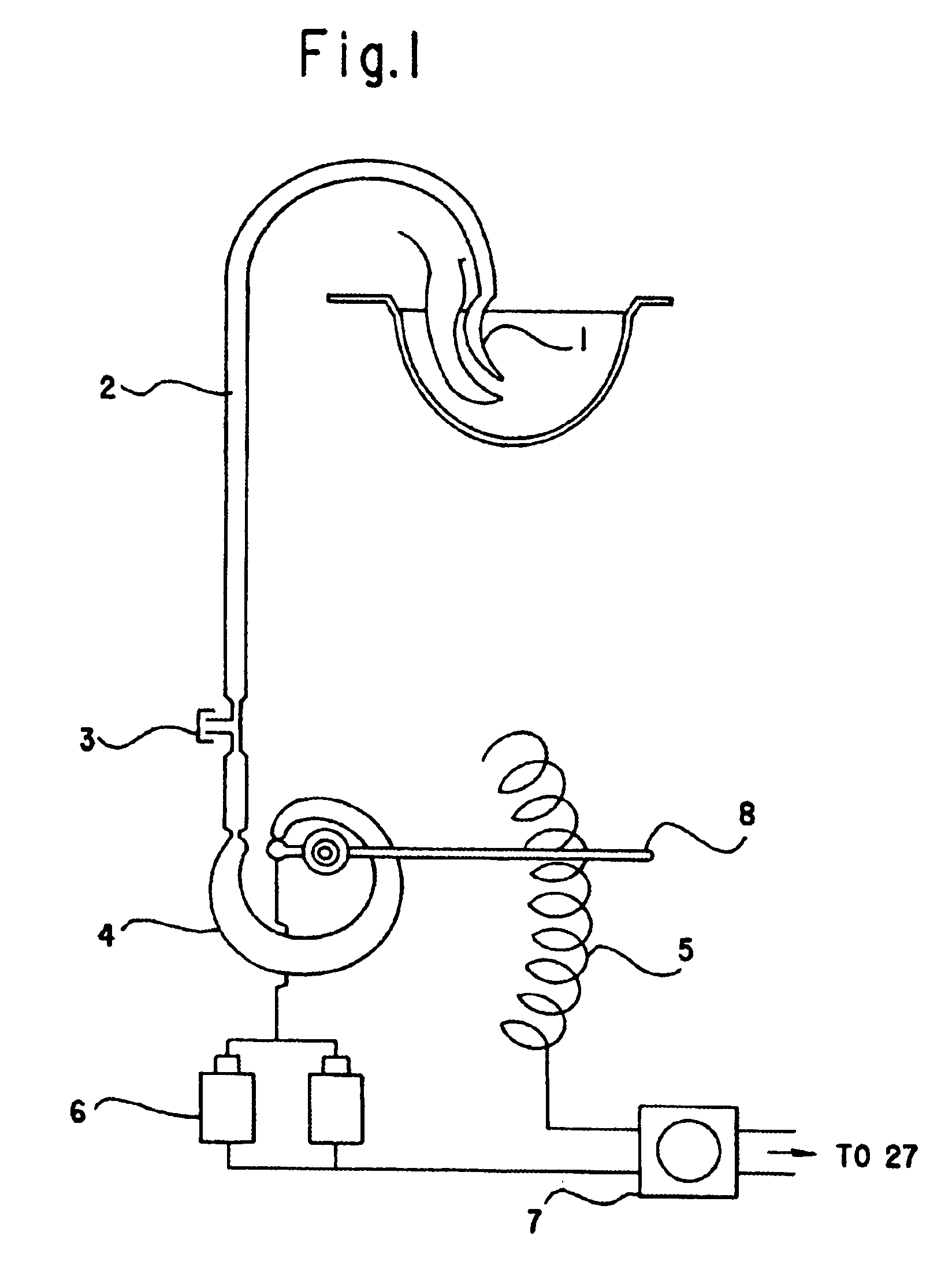

[0035]a device for actuating the invention will now be described referring to FIG. 2.

[0036]According to this embodiment, the conversion of the pressure exercised on the trigger 11 of a firearm (not represented) is realized by a mechanical system mounted on the mechanism of this firearm.

[0037]The device includes a rheostat 5. The rheostat 5 is driven by a system of rack 18 and gears 19. The rack 18 consists of a toothed partial crown situated in the prolongation of the trigger. It rotates around a fixed axis 16. It is pushed back, at the end near the toothed crown, by a spring 17, and pulled, at its other end 9, by the trigger 11. The latter, rotating around a fixed axis 15, is in turn pushed back by a spring organ. It is precisely this spring organ which creates the pressure to be mastered. The gears (e.g., the number of necessary gears and the number of teeth of each gear) are calculated in such a way that the stroke of the rack 18 corresponds to that of the rheostat 5. As before, ...

third embodiment

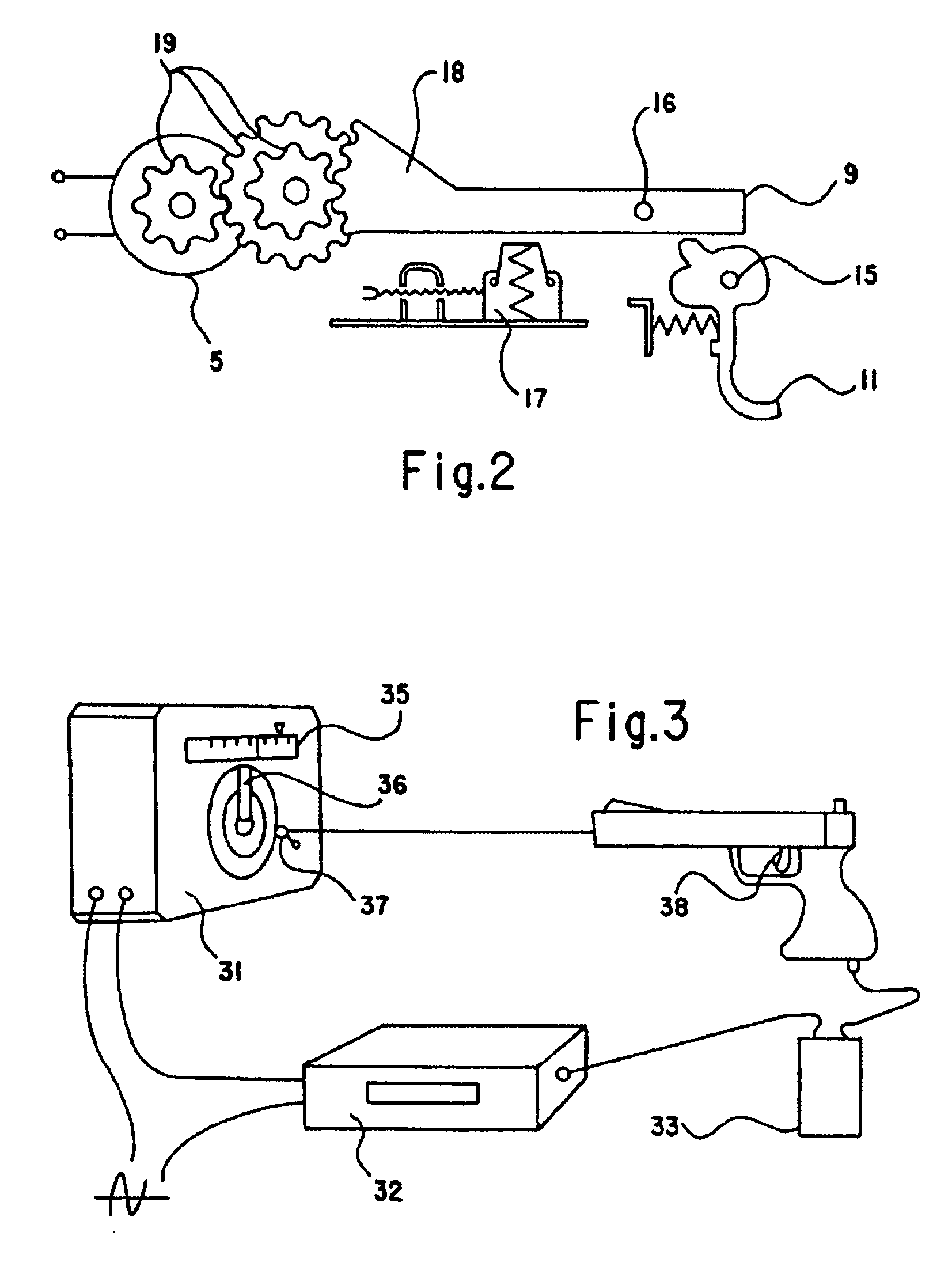

[0038]a device for actuating the invention will be described referring to FIG. 3.

[0039]According to this embodiment, the conversion of the pressure exercised on the trigger 11 of a firearm is realized by using a piezoelectric pressure sensor or a similar sensor (quartz, ceramic, etc.).

[0040]The pressure sensor 38 is:[0041]placed on the trigger, in a housing out of which it protrudes in order to be in contact with the marksman's finger (not represented) on the simulation firearm, as disclosed in FIG. 3;[0042]clipped by its support in plastic material shaped in mortise profile and adapted to the profile of the trigger and constituting its tenon; or[0043]placed on a glove or a glove finger, in such a way that it is positioned between the finger and the trigger (on a real firearm).

[0044]The sensor 38 is connected to an electronic amplifier. The latter amplifies the signal and, if necessary, adapts it for further usage (impedance adaption, percolation, etc.). The amplifier is housed in a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com