Air dryer reservoir module components

a technology of air dryer and reservoir, which is applied in the direction of brake components, braking systems, separation processes, etc., can solve the problems of limited speed of heavy vehicles and limit the use of heavy vehicles with severely leaking reservoirs, and achieve the effect of reducing potential failure modes and cost effectiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

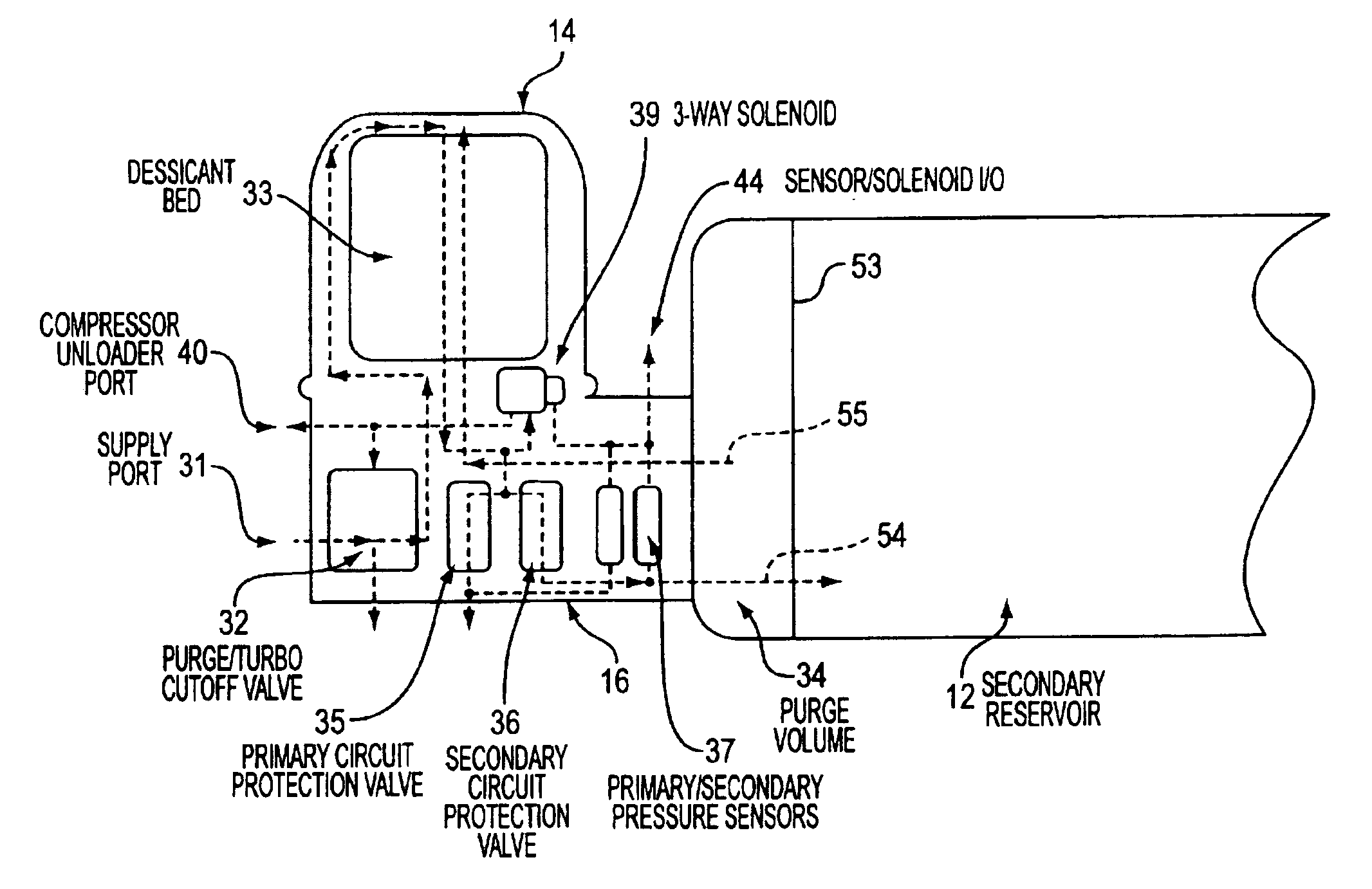

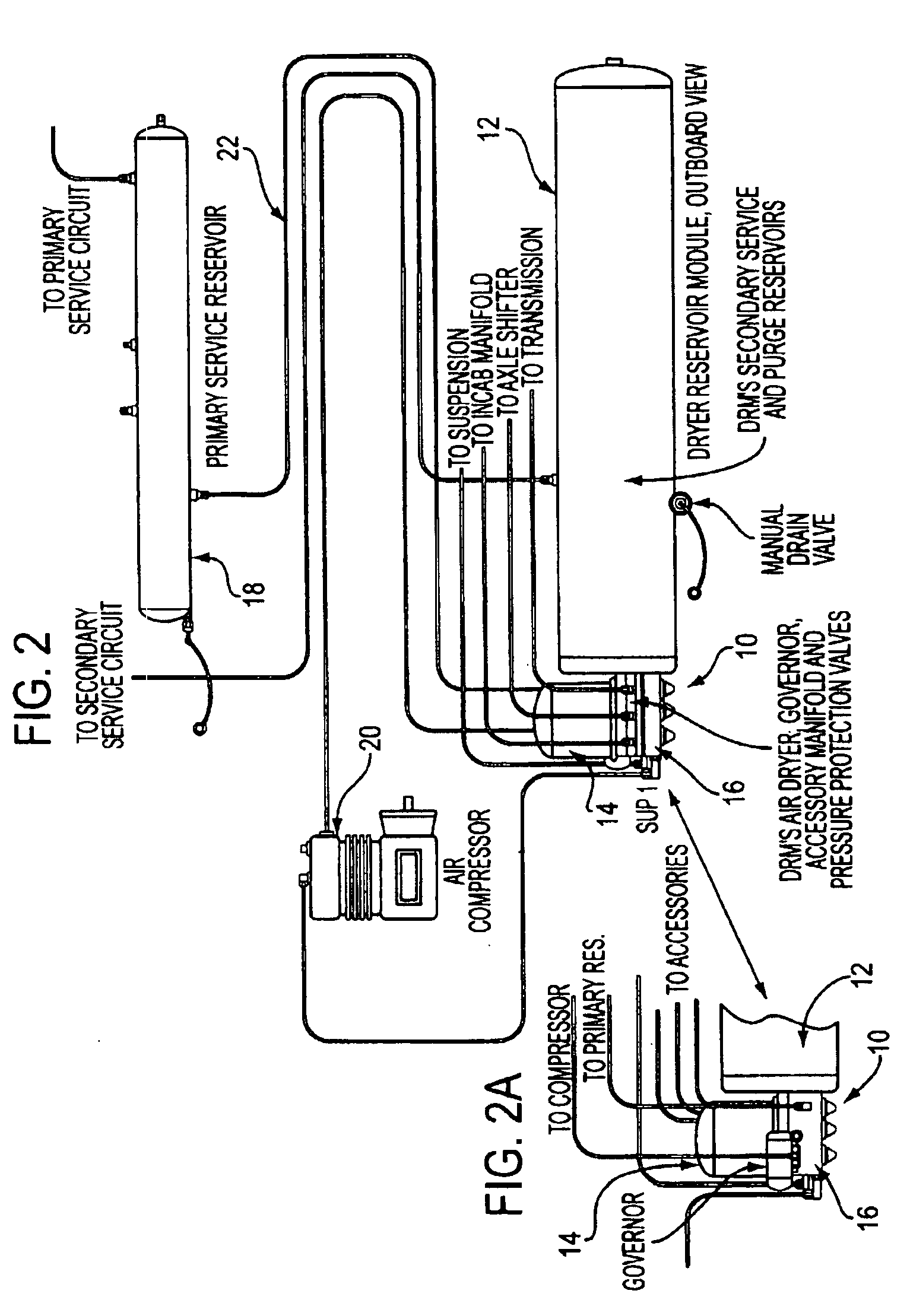

[0020]Referring now to the drawings and FIGS. 2 and 3 in particular there is shown an air dryer reservoir module 10 according to the present invention. The air dryer module 10 provides compressed air received from an air compressor 20 for operating the brakes of a heavy motor vehicle. The air dryer module 10 includes an air dryer 14 connected to receive compressed air from the air compressor 20, a secondary air reservoir 12 separate from the air dryer 14, and a housing 16 containing pneumatic circuit components for controlling the flow of compressed air from the air compressor 20 through the air dryer 14 to the secondary reservoir 12 and a primary reservoir 18. The housing 16 has the air dryer 14 securely attached to one section thereof and the secondary reservoir 12 securely attached to another section thereof for joining the air dryer 14 and the secondary reservoir 12 together forming the unitary air dryer reservoir module 10. The compressed air brake system with the air dryer res...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com