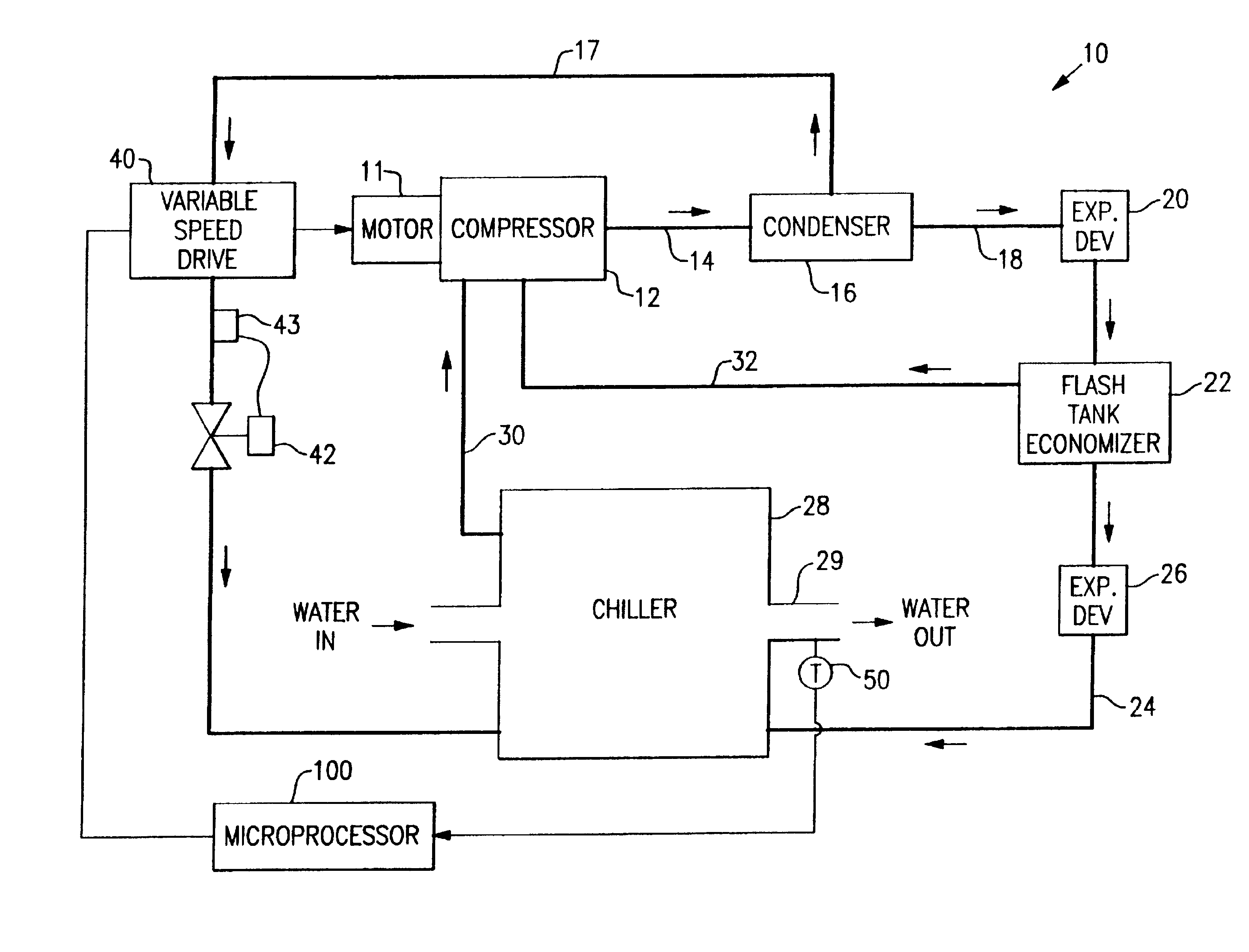

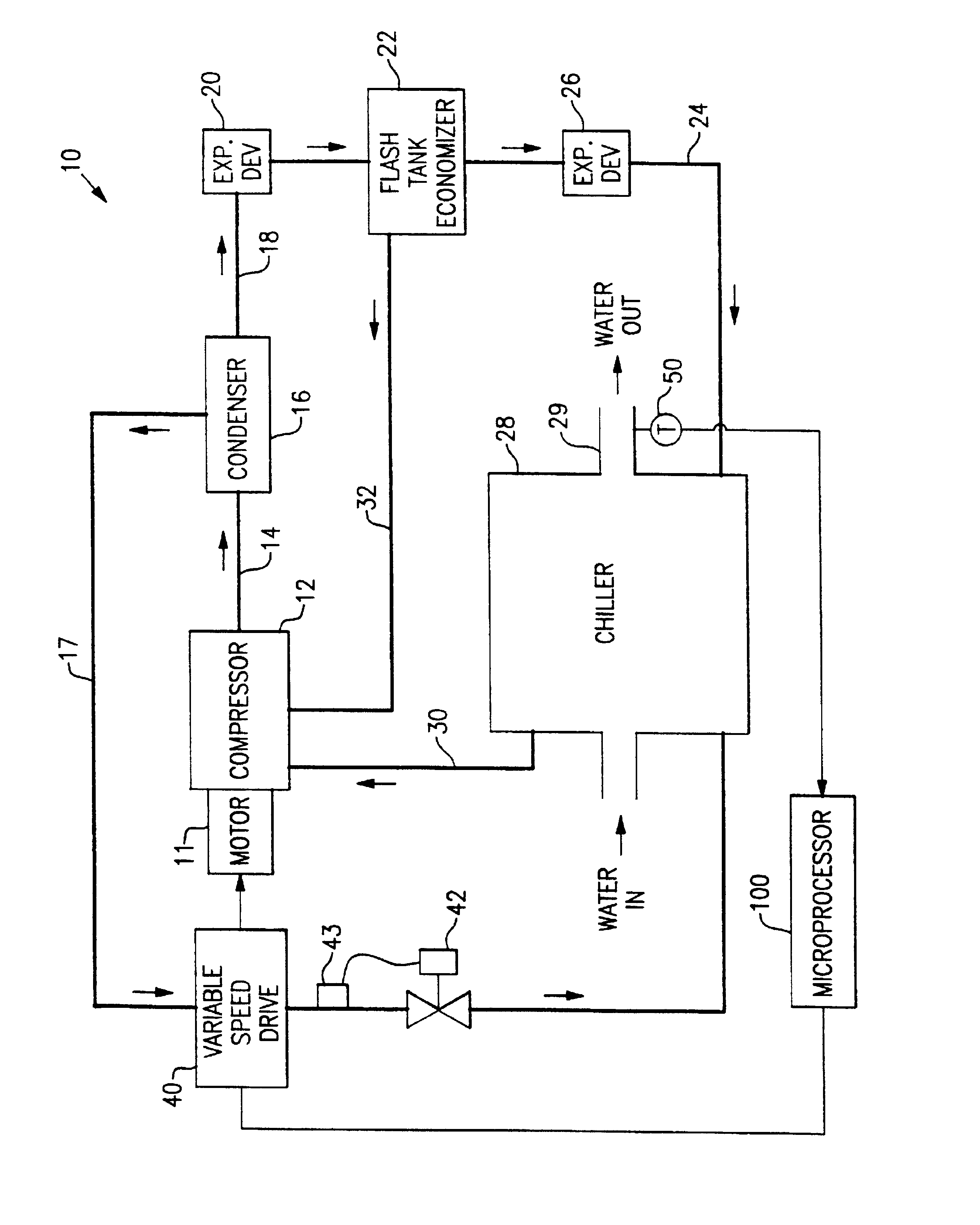

Variable speed drive chiller system

a chiller system and variable speed technology, applied in the field of variable speed drive chiller systems, can solve the problems of adding a variable speed drive to a conventional compressor, greatly increasing the cost, and adding a degree of redundancy, so as to minimize the initial cost and minimize the operating cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014]For a refrigeration system a particular system capacity is the starting point in designing the system. A compressor capable of producing the required capacity will be chosen based upon factors such as cost, efficiency and operating speed. The selection of the compressor will be in conjunction with the selection of the motor. Motors are available having power factors in the range of 0.80 to 0.93 and the motor will be selected based upon cost, power factor, efficiency at design compressor speed. Variable speed drives are available which have power factors running from 0.99 to unity. However, the differences between the standard sizes of the variable speed drives are relatively large such that a considerably oversized variable speed drive might be the smallest standard drive available sufficient to meet design requirements. By cooling the variable speed drive with refrigerant from the condenser, it may be operated at higher than its air cooled drive design capacity because of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com