Clutch device for magnetic recording/reproducing apparatus

a technology of magnetic recording/reproducing apparatus and clamping device, which is applied in the direction of gearing, slip coupling, speed-changing/reversing arrangement, etc., can solve the problems of reducing the operation efficiency of the assembly process, increasing production costs, and increasing production costs due to the large amount of construction parts. , to achieve the effect of reducing production costs, reducing the number of components, and improving assembly operation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056]Hereinafter, the preferred embodiments of a clutch device for a magnetic recording / reproducing apparatus in accordance with the present invention will be described with reference to accompany drawings.

[0057]Although there may be a plurality of embodiments of a magnetic recording / reproducing apparatus in accordance with the present invention, hereinafter the preferred embodiment will be described.

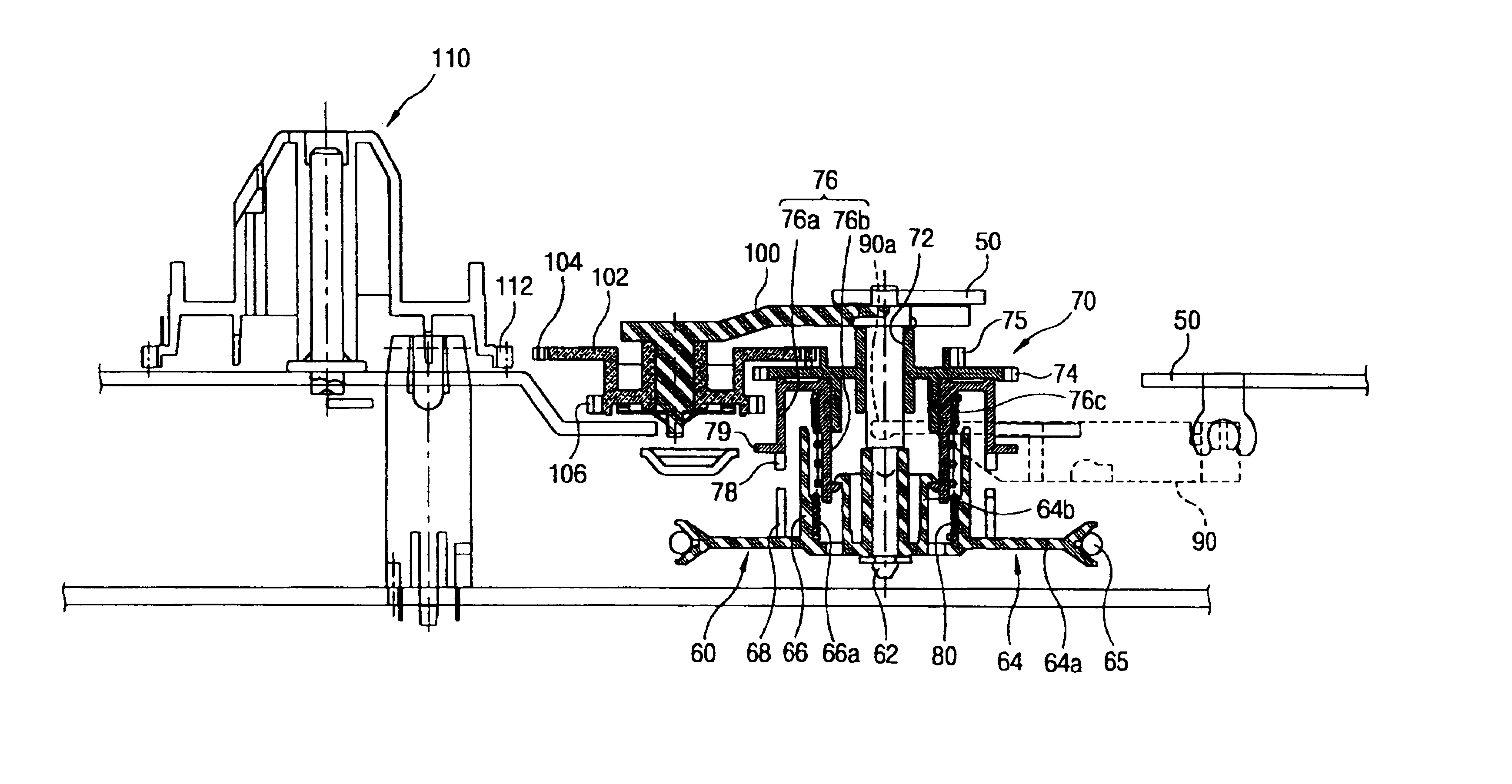

[0058]As depicted in FIG. 4, a clutch assembly 60 is installed on a main chassis 50. In conveying a tape T by transmitting power provided from a capstan motor to a supply reel and a winding reel, the clutch assembly 60 performs the conveyance of the tape T with a regular tension, regardless of the quantity of the tape T wound around the supply reel and winding reel.

[0059]In the structure of the clutch assembly 60, a central shaft 62 is formed on the main chassis 50. A driving pulley 64 is rotatably installed at the central shaft 62. The driving pulley 64 receives power transmitted from...

PUM

| Property | Measurement | Unit |

|---|---|---|

| inner diameter | aaaaa | aaaaa |

| outer diameter | aaaaa | aaaaa |

| torque | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com