Rollover pressure car wash apparatus and methods of operating same

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

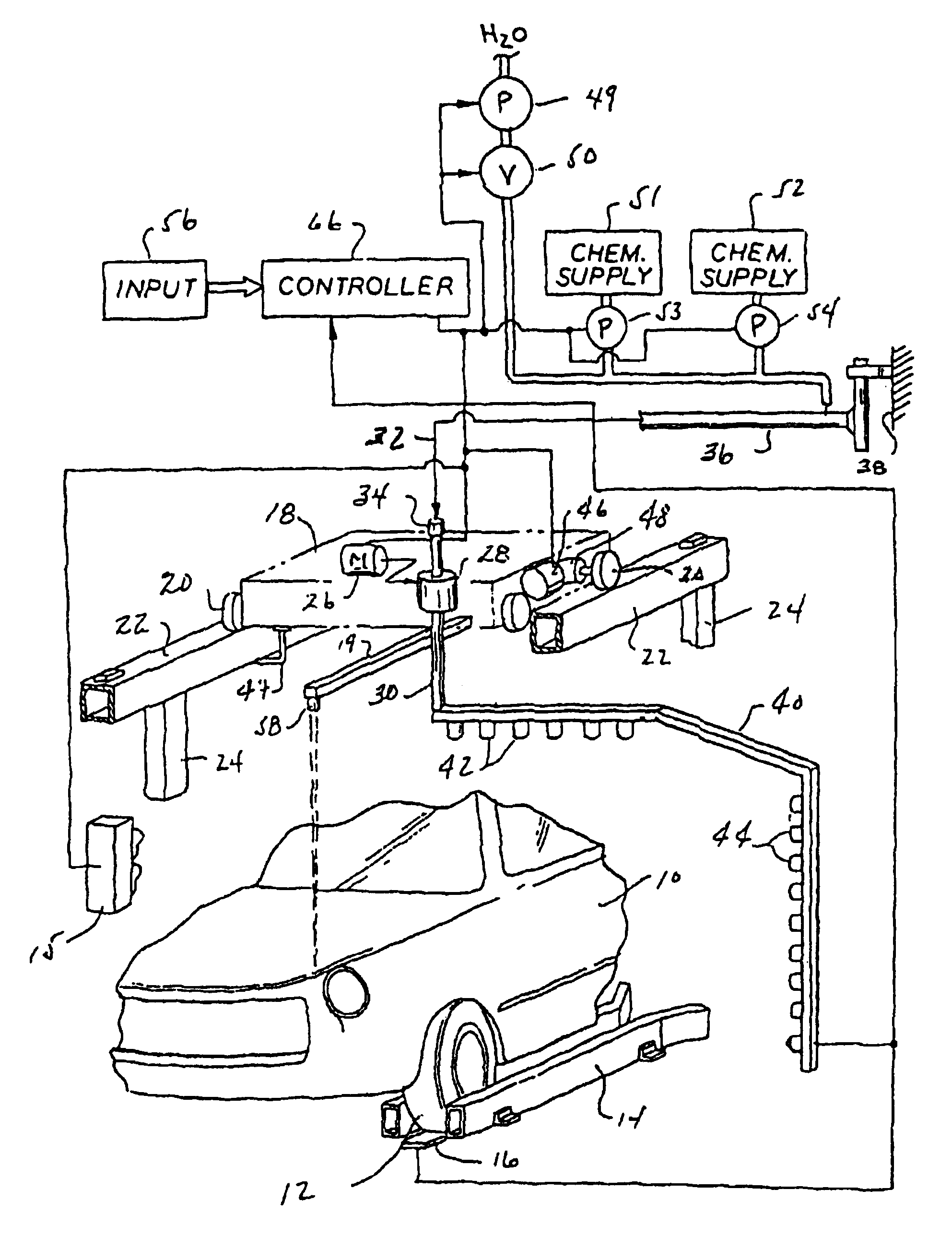

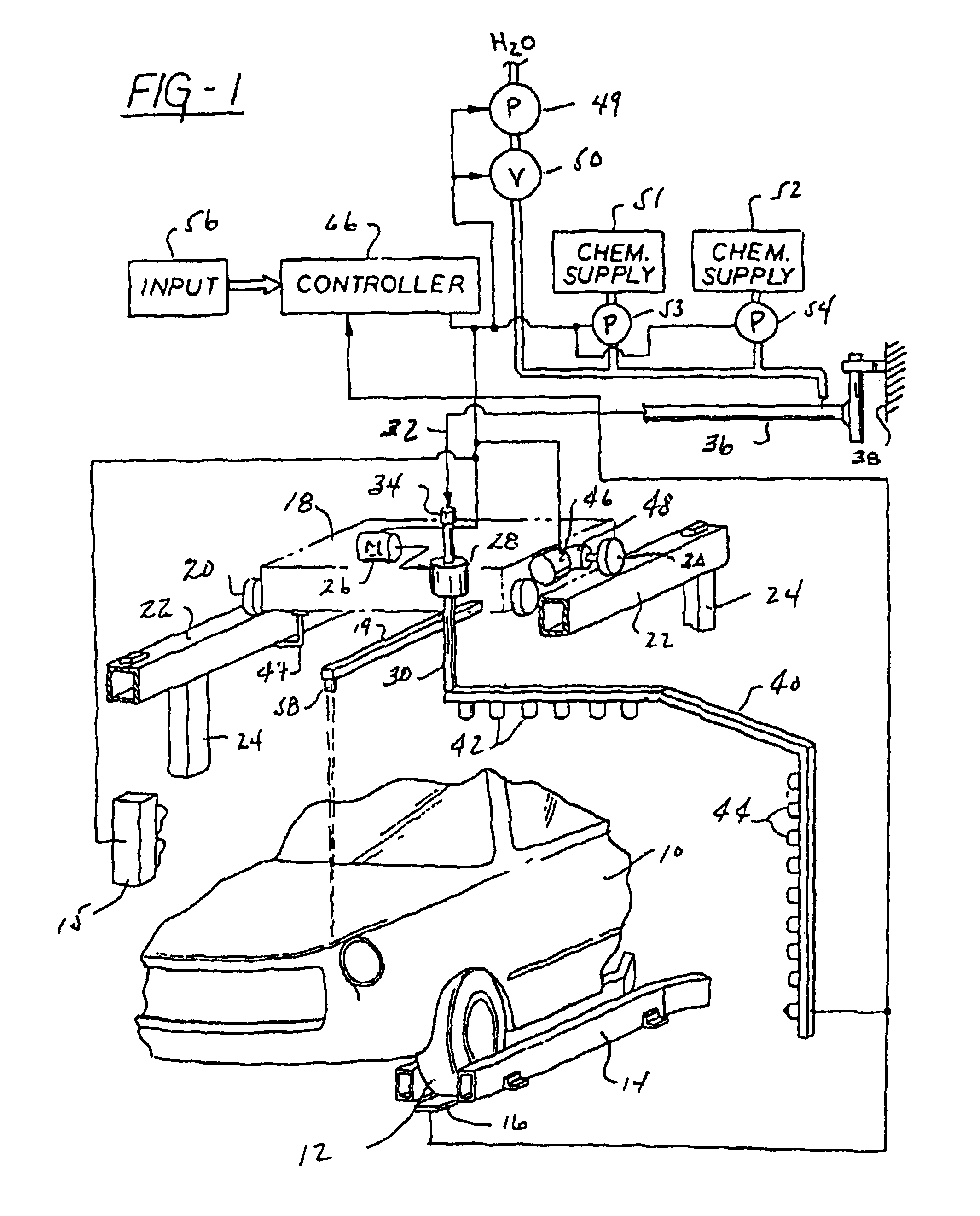

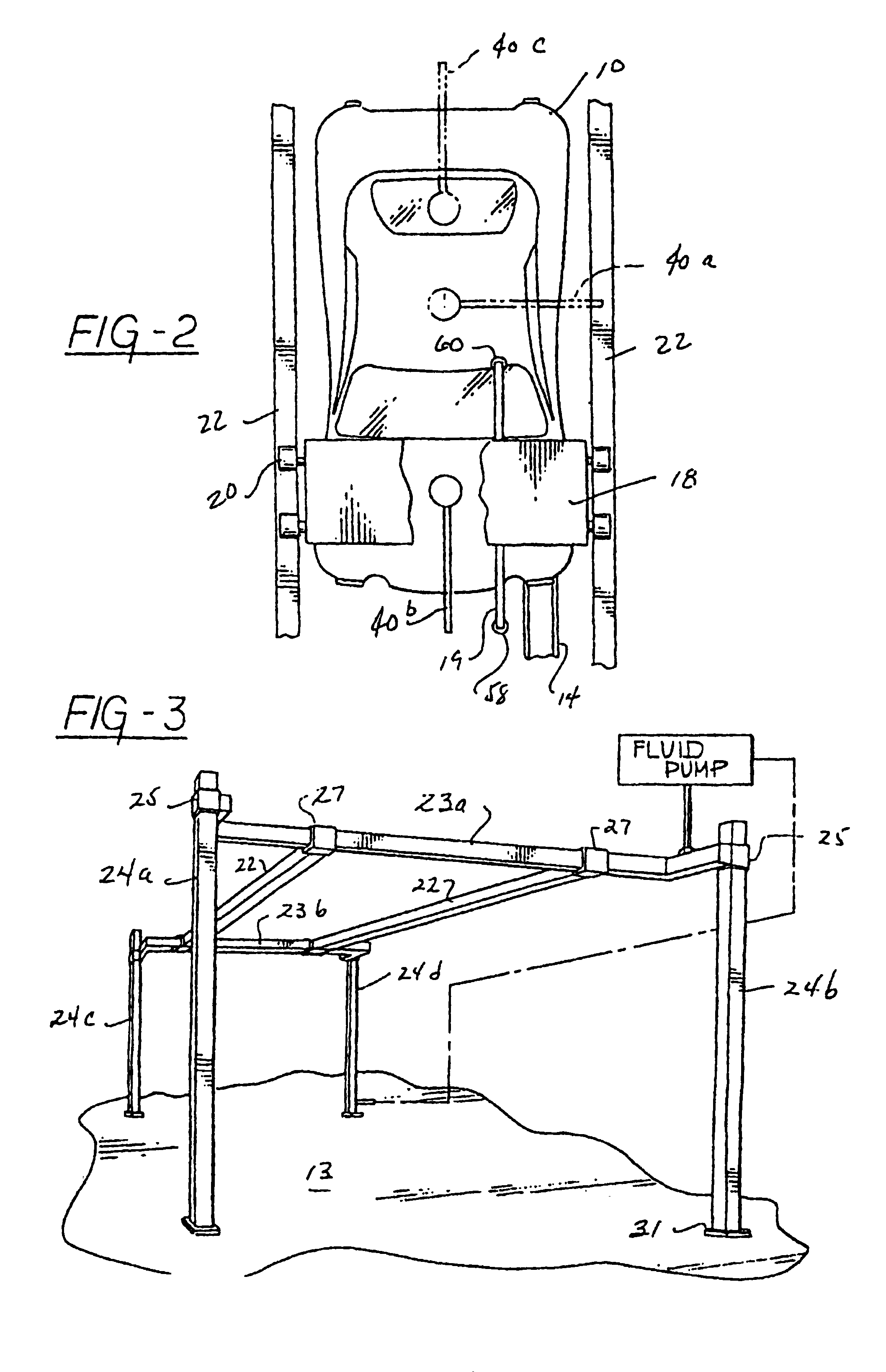

[0027]Referring first to FIGS. 1 and 2 where the components of a single-arm embodiment are schematically shown, a representative portion of a conventional passenger vehicle 10 has a front left wheel 12 positioned by guides 14 suitably attached to the floor of a vehicle laundry bay. A treadle 16 is mounted on the floor of the bay near the forward extremity of the guides 14. When depressed by the front tire of vehicle 10, treadle 16 generates an electrical signal providing input data to a controller 66 to operate a signal light 15 providing stop and go cues to the driver of vehicle 10. Treadle 16 also provides the driver with a tactile cue that the vehicle is in the correct position.

[0028]The foregoing and following description assumes that the vehicle 10 is driven into the laundry bay, properly located and driven forward out of the bay by a driver at the proper times. As persons skilled in the art will know, the wash bay may instead be equipped with a conveyor to position the vehicle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com