Practice ammunition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

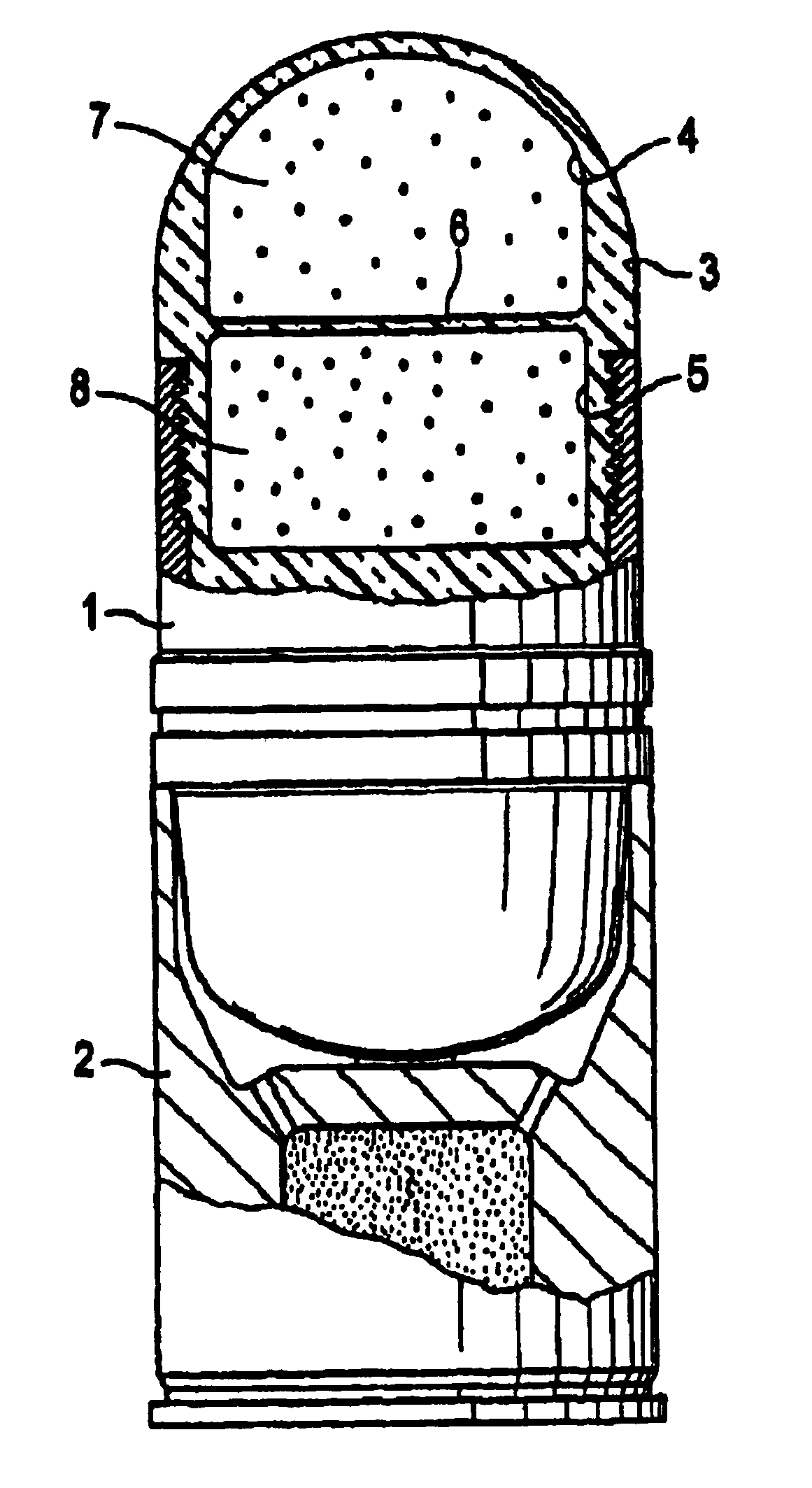

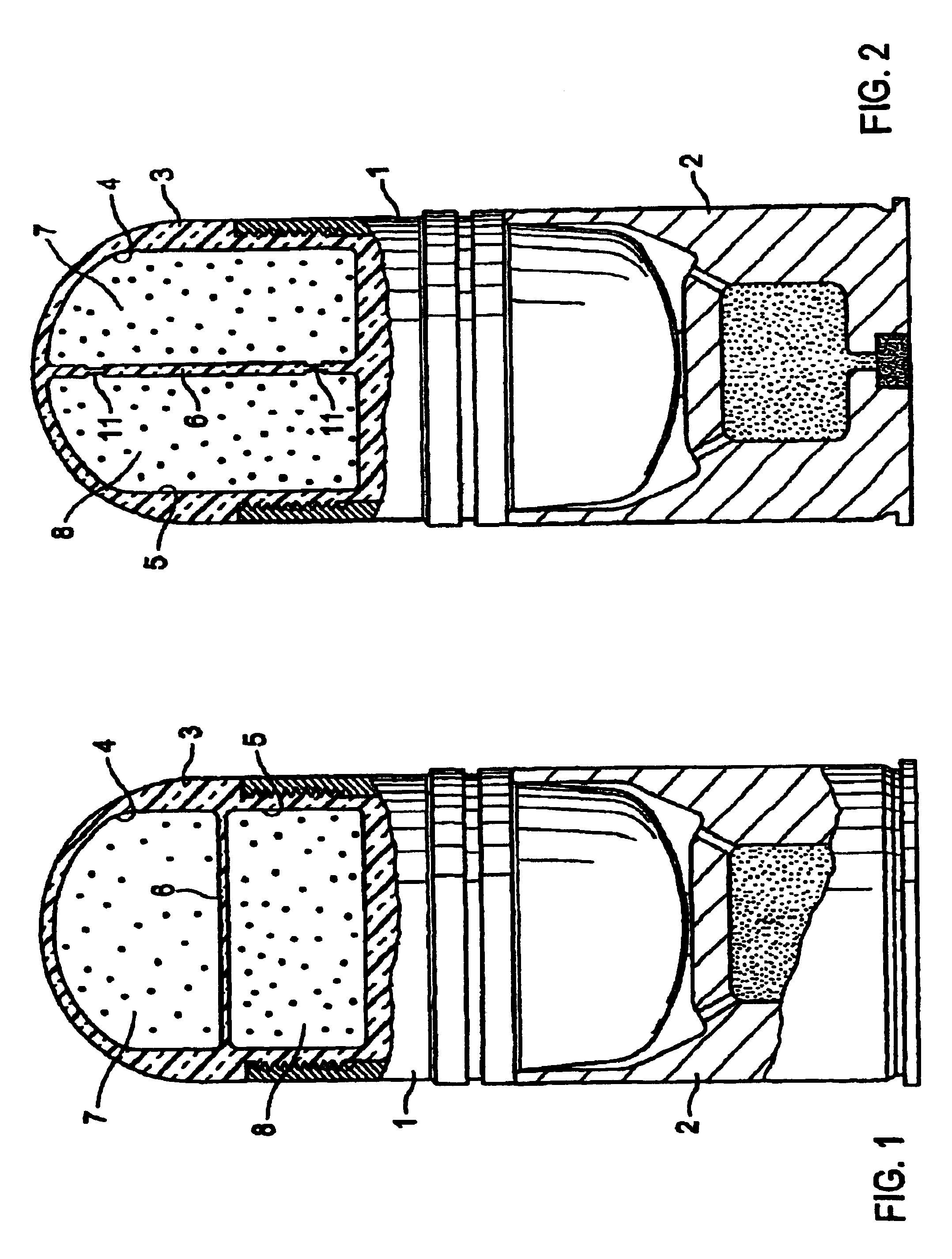

[0014]The preferred embodiments of the present invention will now be described with reference to FIGS. 1 and 2 of the drawings. Identical elements in the various figures are designated with the same reference numerals.

[0015]FIG. 1 shows a practice projectile 1 received in a cartridge case 2. The head of practice projectile 1 has a hood 3 consisting of a transparent material—such as a plastic material—and covering a first compartment 4 and a second compartment 5. The two compartments are arranged one on top of the other and are separated from each other by a partition 6 therebetween. The first compartment is filled with a first chemical component 7 such as an oxidant and the second compartment is filled with a second chemical component 8 such as a reducing agent.

[0016]When the partition is broken up by the force of the acceleration generated during firing, for example, the chemical reaction of the two chemical components causes chemoluminescent light to be emitted which is visible th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com