Mark forming apparatus, method of forming laser mark on optical disk, reproducing apparatus, optical disk and method of producing optical disk

a mark forming and laser mark technology, applied in the field of mark forming apparatus, can solve the problems of copyright owner financial loss, infringing copyright owners' rights, spreading of pirated disks, etc., and achieve the effect of preventing pirated disk production, high degree, and preventing piracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

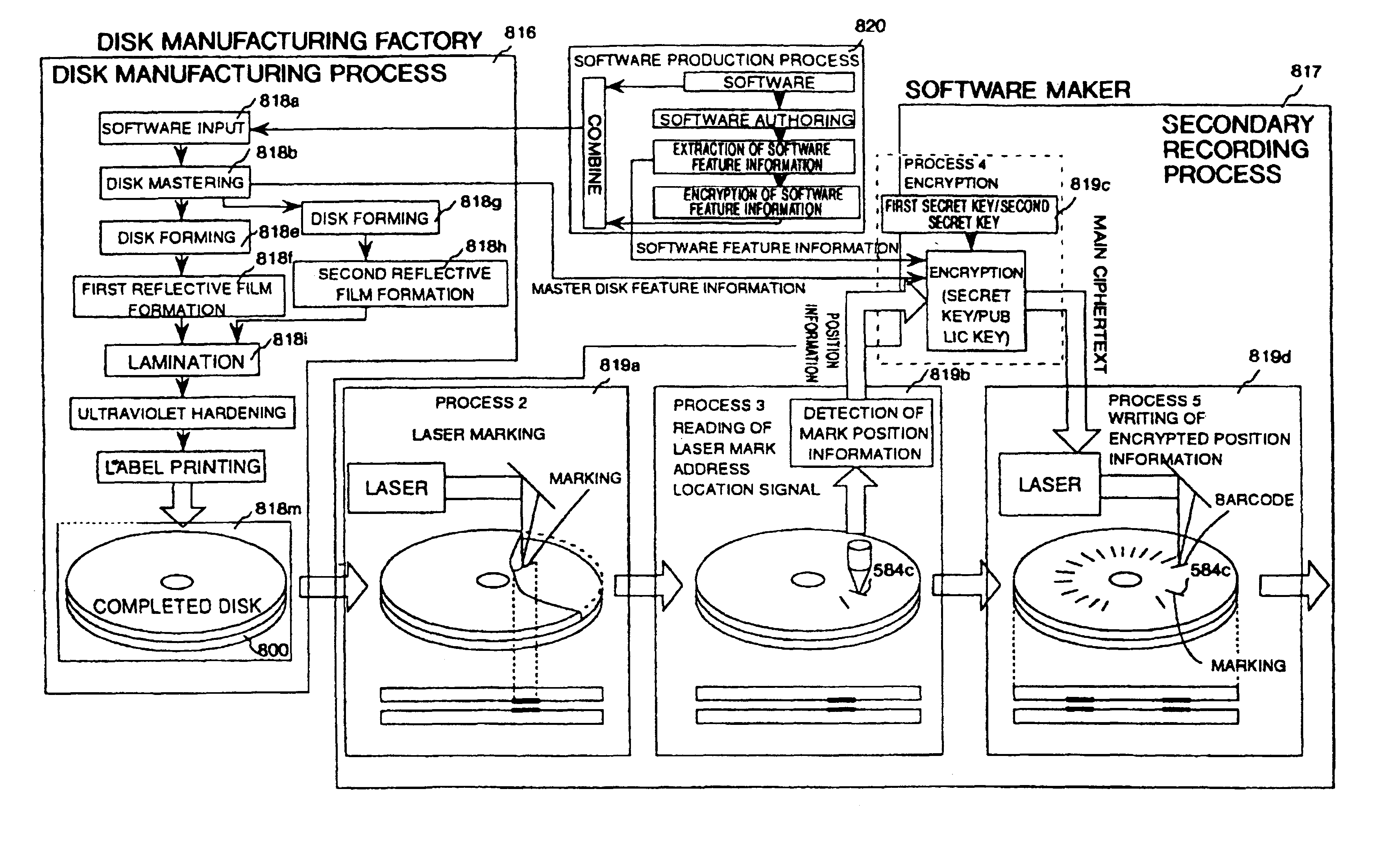

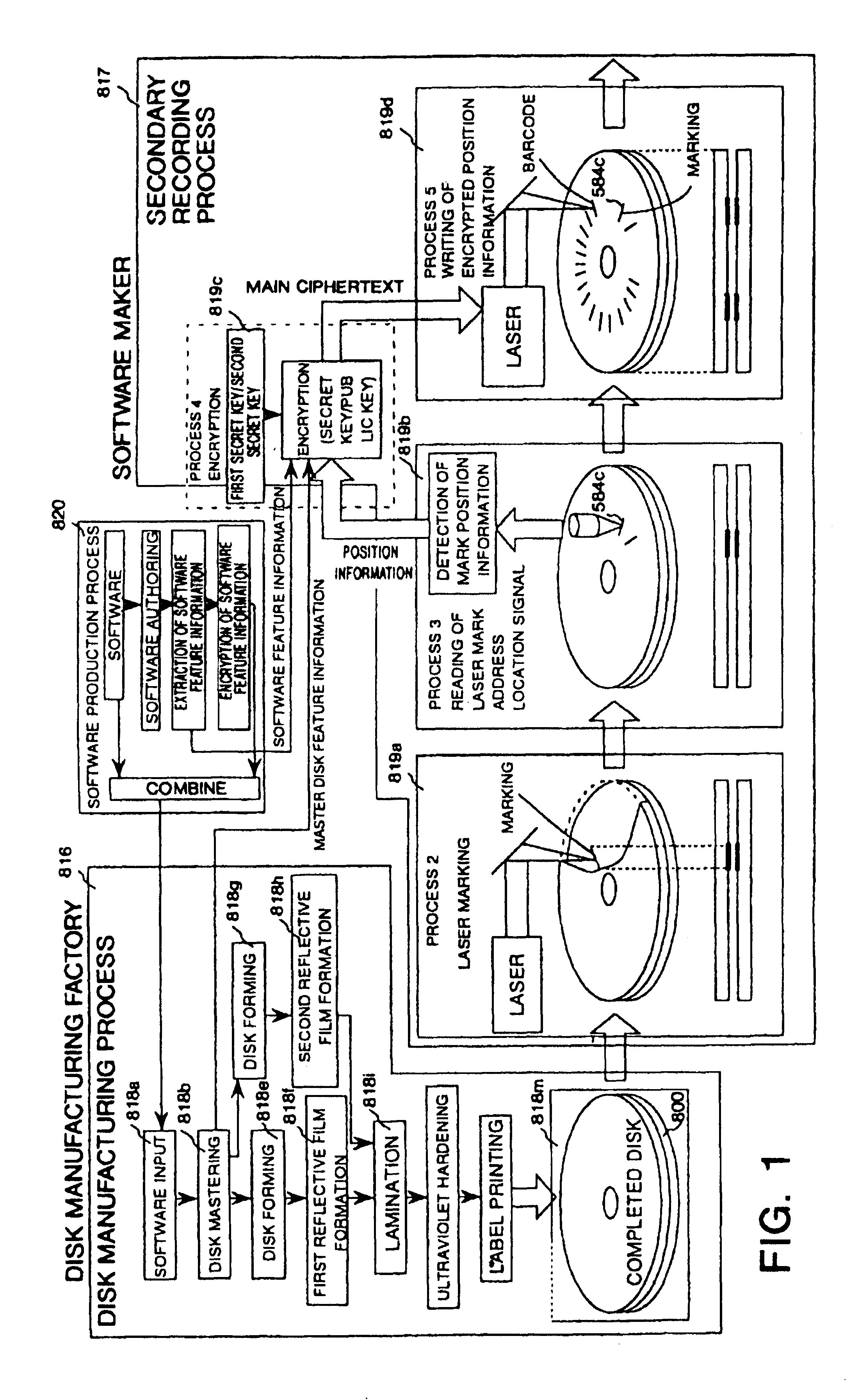

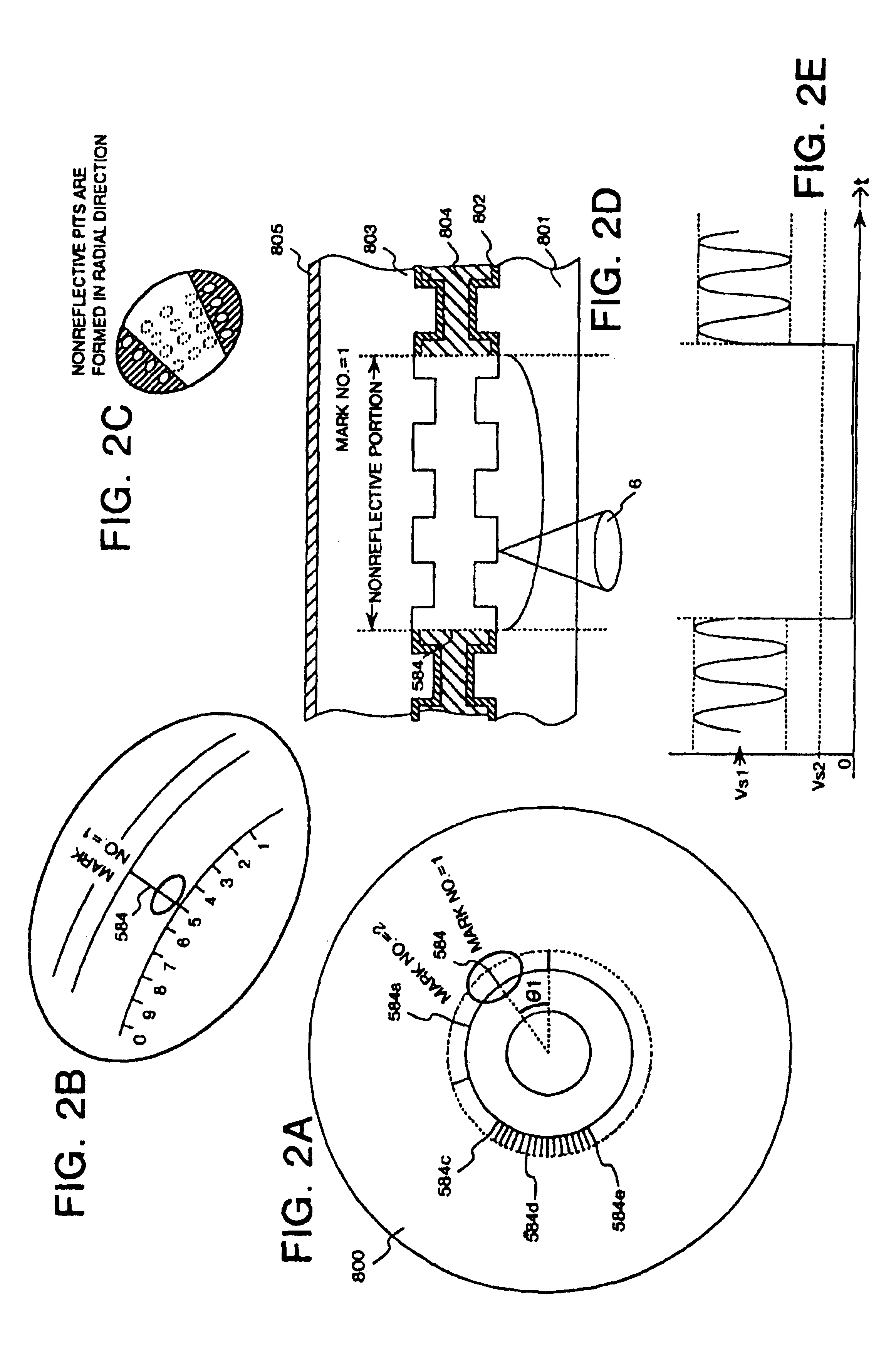

[0078]The constitution and operation of a marking forming apparatus, a method of forming a laser marking to an optical disk, a reproduction apparatus, an optical disk, and a method of manufacturing an optical disk will be described below in accordance with an embodiment of the present invention.

[0079]In the description of the present embodiment given herein, the first half part (1) deals with such operations as manufacturing a disk, forming a marking by using a laser, reading position information of the marking, performing encryption and other processing on the position information, etc. for writing on an optical disk, and reproducing the optical disk on a player. The encryption and reproduction operations are briefly described in the first part (1).

[0080]Next, in the second half part (2), the encryption and other processing of the marking position information, etc. and the decryption and reproduction of the position information, etc. on the optical disk, briefly described in the fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com