High speed baggage diverter

a high-speed, baggage technology, applied in the direction of conveyor parts, mechanical conveyors, transportation and packaging, etc., can solve the problems of increasing the difficulty of separating, baggage may be more susceptible to damage than articles, and the difficulty of sorting is even more difficult than sorting, so as to reduce the rate at which articles are handled and the impact of articles being diverted is minimal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

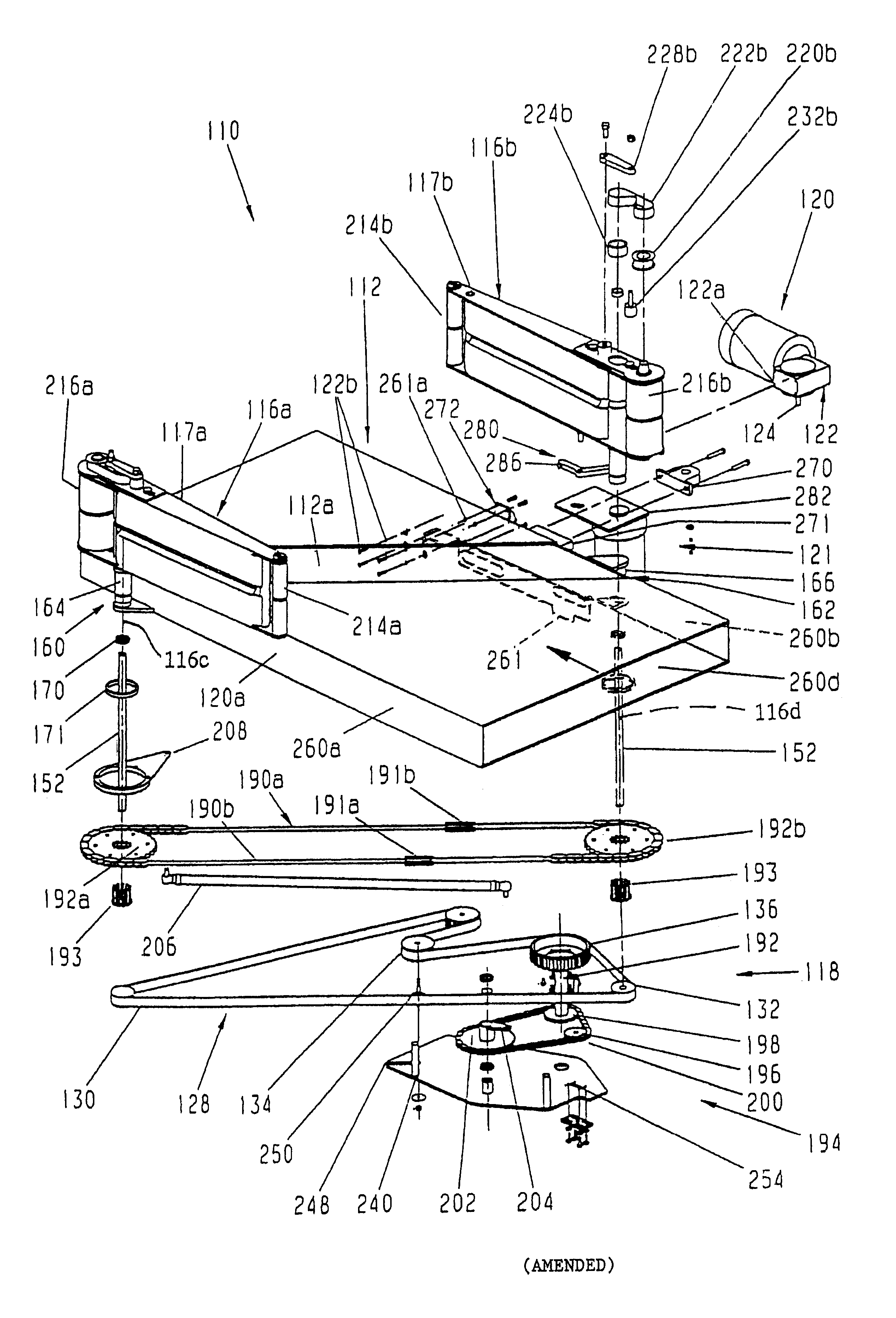

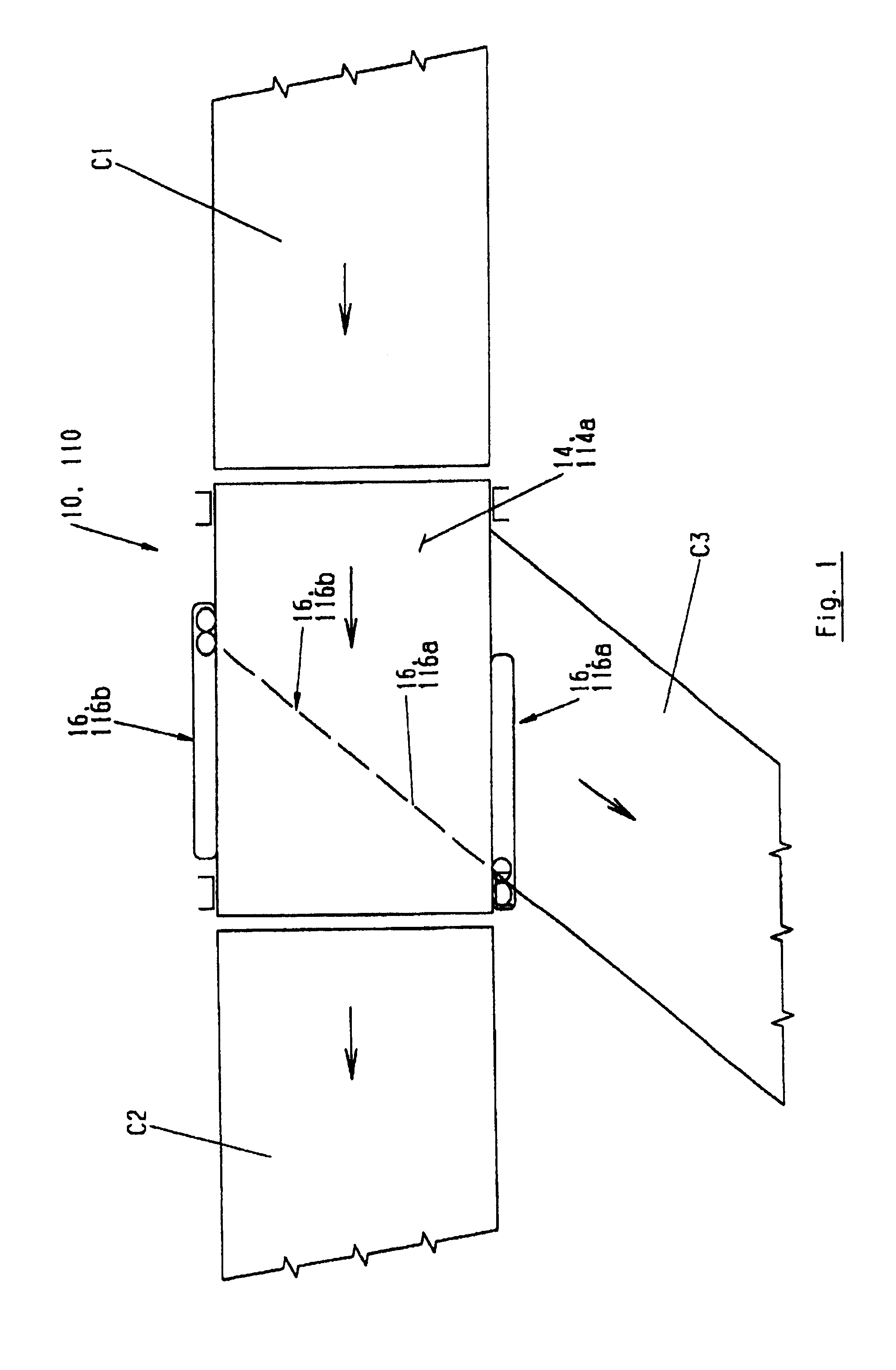

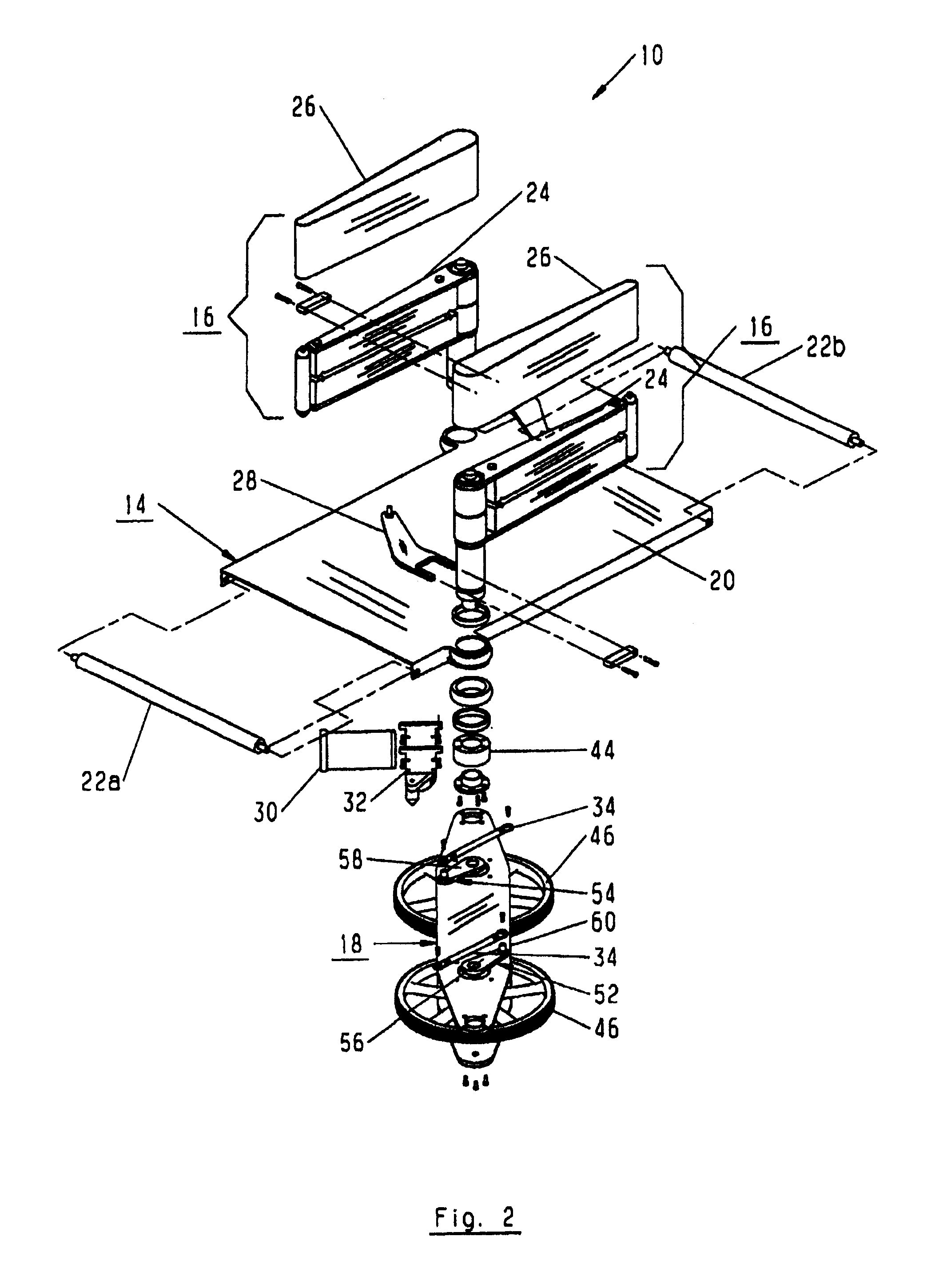

[0052]Referring to the drawings and the illustrative embodiments depicted therein, the numeral 10 generally designates a high-speed diverter assembly of the present invention. High-speed diverter assembly 10 is particularly suitable for diverting articles, such as baggage, and is typically positioned between two conveyor sections C1 and C2 so that articles conveyed on, for example, C1 may be diverted to a take-away conveyor section or chute C3 (FIG. 1), which is positioned adjacent diverter assembly 10. High-speed diverter assembly 10 includes a horizontal conveying surface 14, a pair of flipper assemblies 16, and a flipper actuator or drive assembly 18. Horizontal conveying surface 14 includes a bed or belt support surface 20 and a pair of guide pulleys or rollers 22a, 22b for supporting a driven belt (not shown), which typically would extend well beyond baggage diverter assembly 10. It should be understood that other types of conveying surfaces, such as driven rollers, or the like...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com