Clamping device for a cutting insert

a technology of cutting inserts and clamping devices, which is applied in the field of clamping devices for cutting inserts, can solve the problems of blade jaw wear, key wear, and frictional wear of the jaw and/or key

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

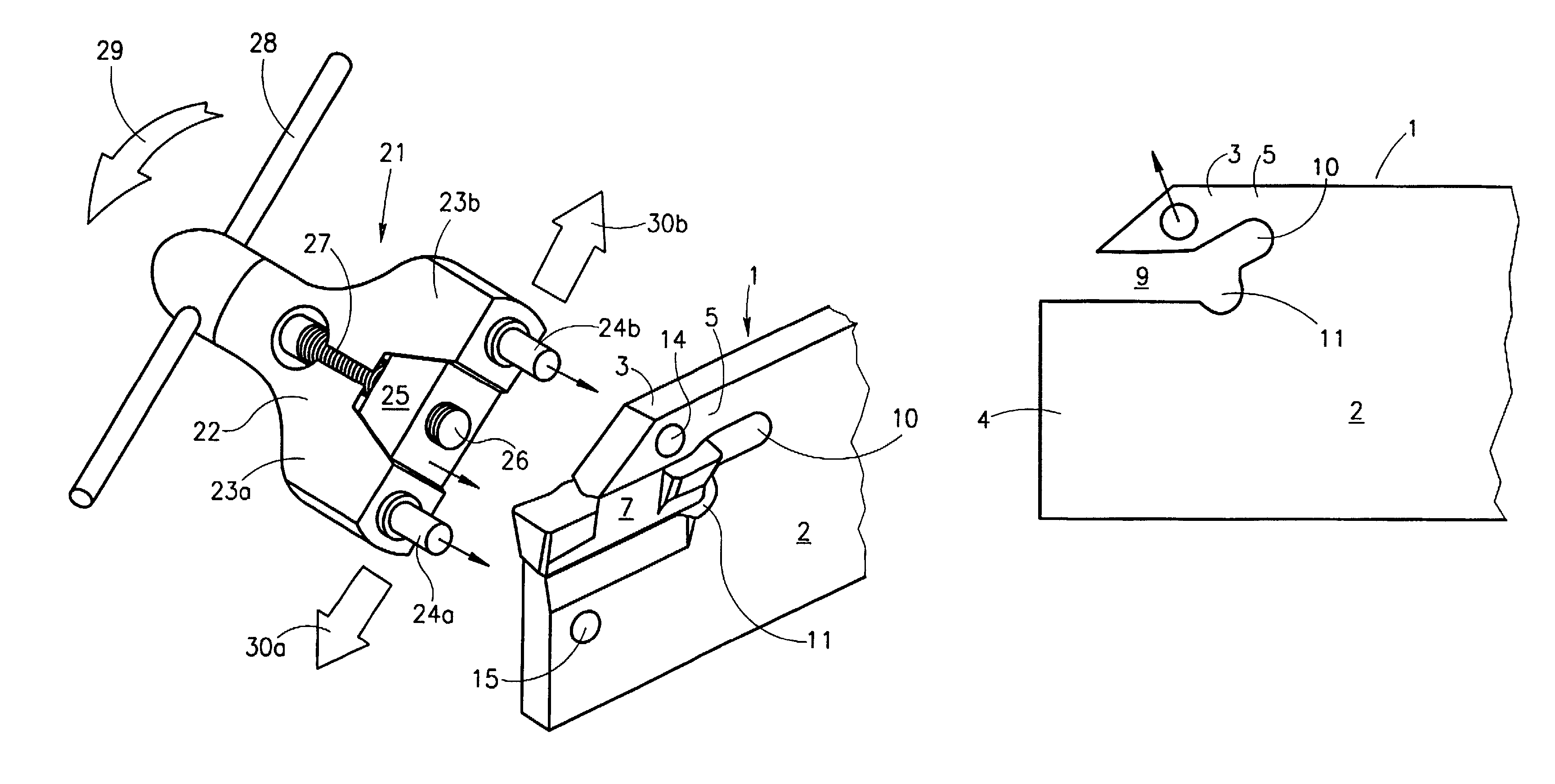

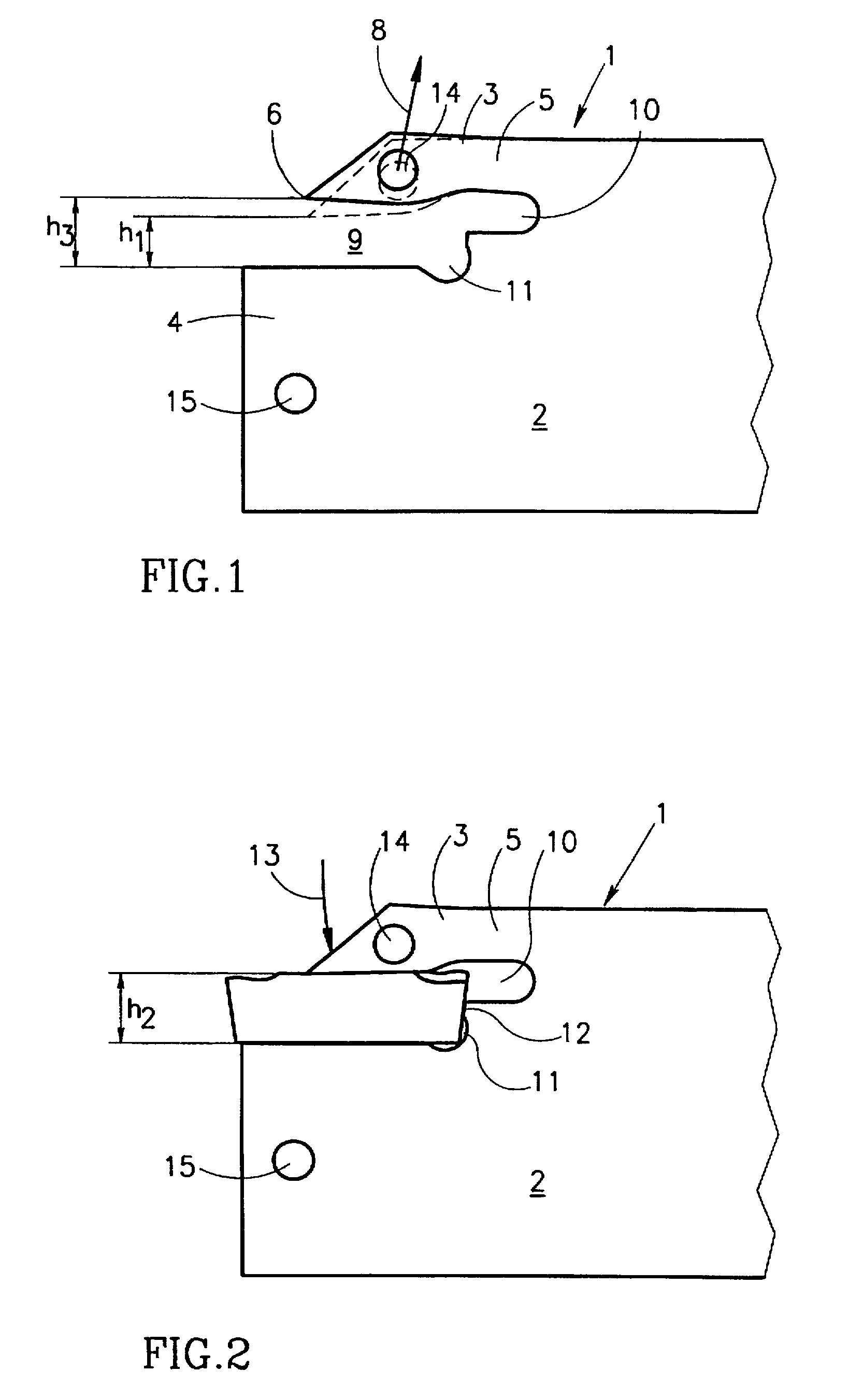

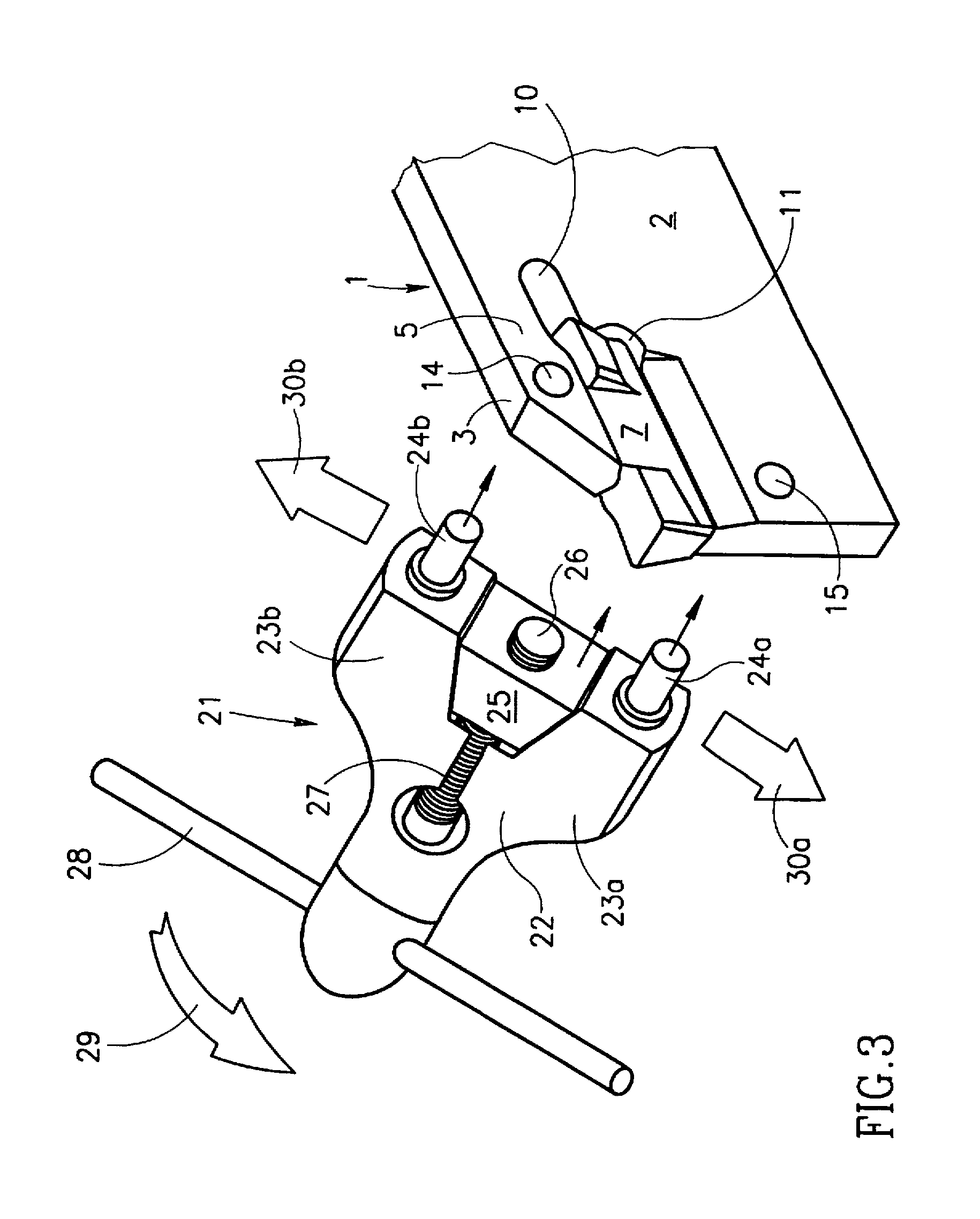

[0023]As seen in FIG. 1 of the drawings, a holder blade 1 for a metal cutting tool assembly in accordance with the present invention comprises a rigid body portion 2 with which are formed integrally a clamping jaw 3 and a base jaw 4. The clamping jaw 3 is coupled to the body portion 2 via a relatively narrow neck portion 5, thereby allowing for a limited degree of flexible resilience of the clamping jaw 3 with respect to the body portion 2 and with respect to the base jaw 4, the latter forming a rigid whole with the body portion 2.

[0024]As can be seen in dotted lines in FIG. 1 of the drawings, the clamping jaw 3, in its unstressed position, has its forward tip 6 directed downwardly towards the base jaw 4 and is spaced therefrom by a distance h1.

[0025]In order to allow for the introduction of an insert 7 (shown in FIG. 2 of the drawings) having a height h2, the clamping jaw 3 must be displaced upwardly in the direction of the arrow 8 (FIG. 1) so mat its forward tip 6 is spaced from t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| displacement | aaaaa | aaaaa |

| displacing force | aaaaa | aaaaa |

| force | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com