Cleaning device for the shaving head of a dry shaving apparatus

A technology for a washer and a shaving head, applied in the field of liquid propulsion devices, can solve problems such as unpleasant noise, hazards, and limited selection, and achieve the effects of rapid emptying, high flow rate, and reduced pump speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

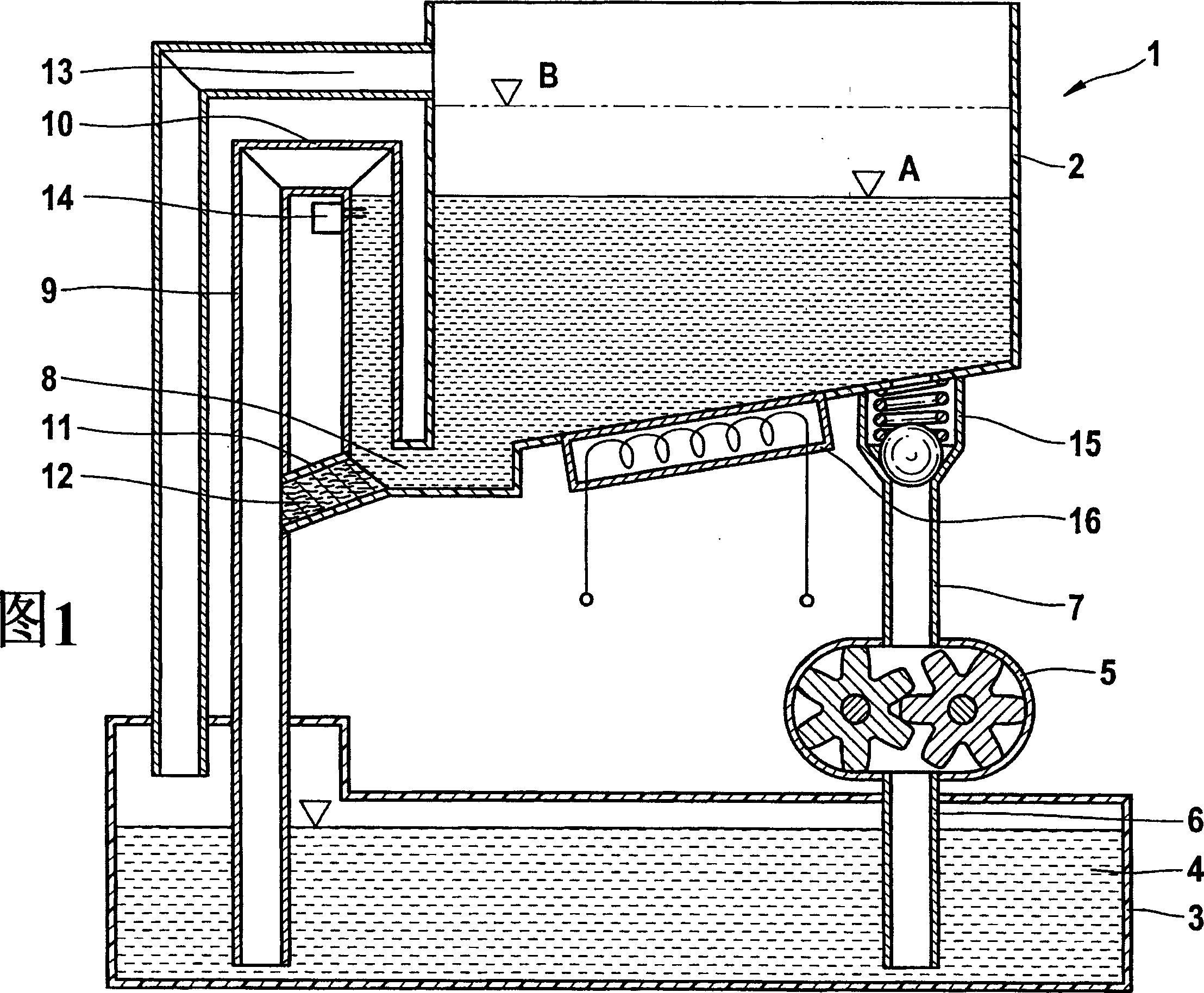

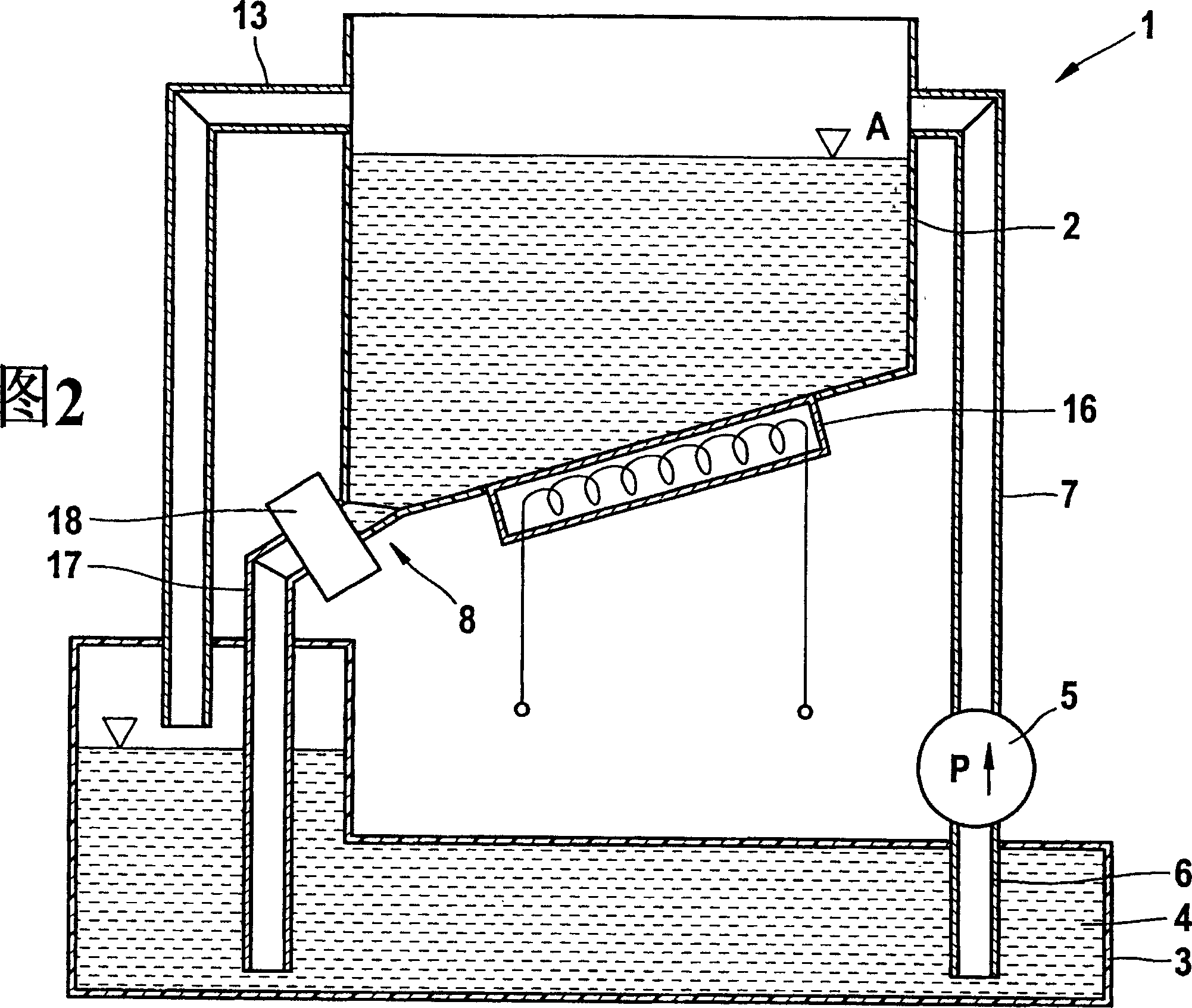

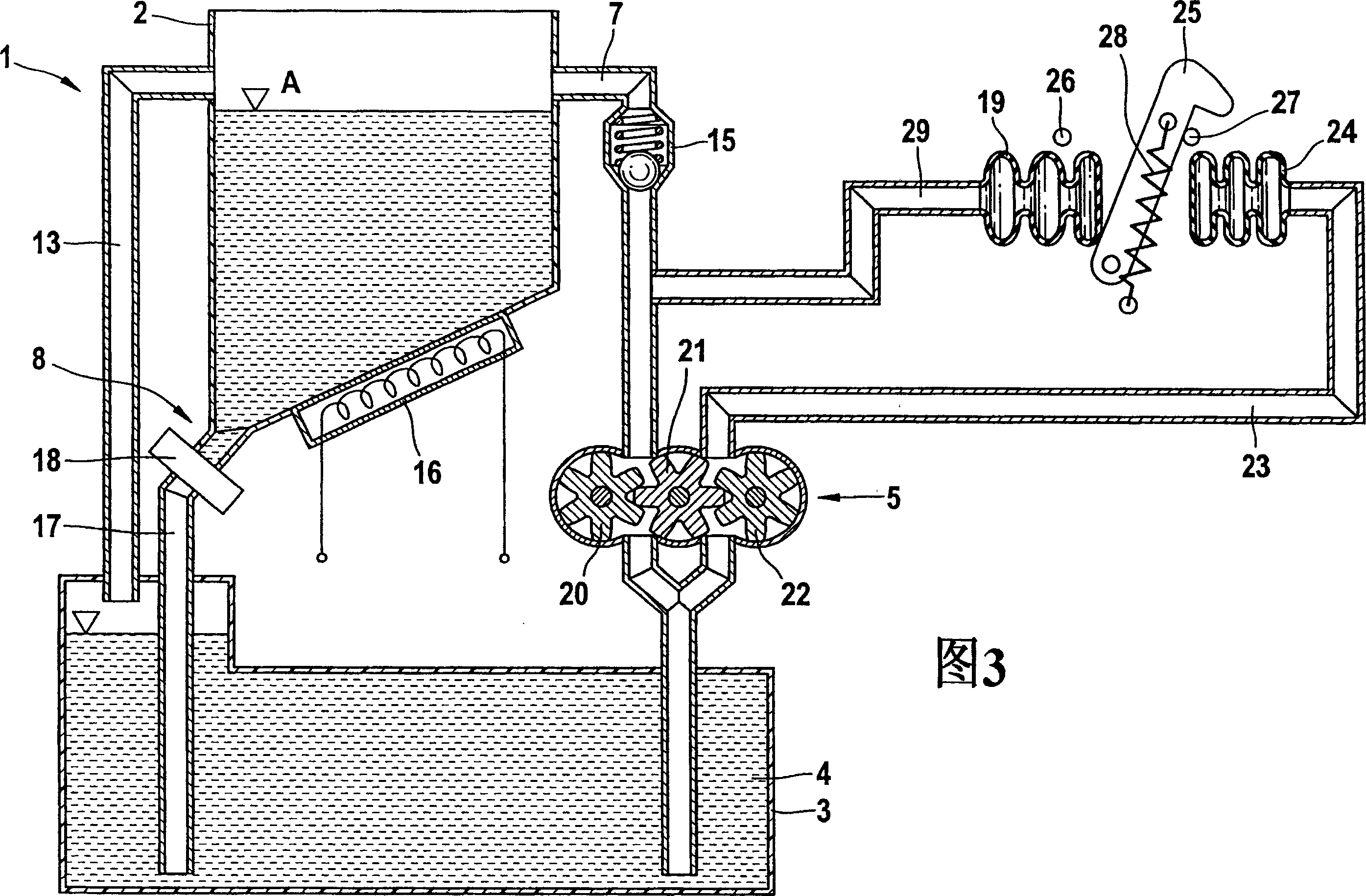

[0030] The washer 1 shown in FIG. 1 has a container 2 and a reservoir 3 for cleaning fluid 4 . The pump 5 is arranged as a propulsion device for driving by an electric motor. The pump 5 is designed as a gear pump. However, any other suitable piston pump or liquid flow pump may be substituted. The pump 5 draws cleaning fluid 4 from the reservoir 3 via a water inlet 6 and delivers it to the container 2 via the inlet 7 . A check valve 15 is disposed in the inlet 7 to prevent the cleaning fluid 4 from being discharged from the inlet 7 . If the pump 5 is designed to prevent the cleaning fluid from returning to the reservoir 3, the non-return valve 15 can be omitted. The shaving head of a dry shaving device (not shown) can be inserted downwards into the container 2 so that the shaving head is completely contained by the container 2 . One end of the pipe 9 is arranged in the lower region 8 of the container 2 . A duct 9 extends upwards from the lower region 8 . In the upper regi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com