Device for forming shed in weaving loom of jacquard type

A loom and pattern technology, which is applied in the directions of jacquard, textile, textile and paper making, can solve the problem of requiring a lot of space for the device, affecting the positioning of the actuator, etc., and achieve the effect of saving equipment space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

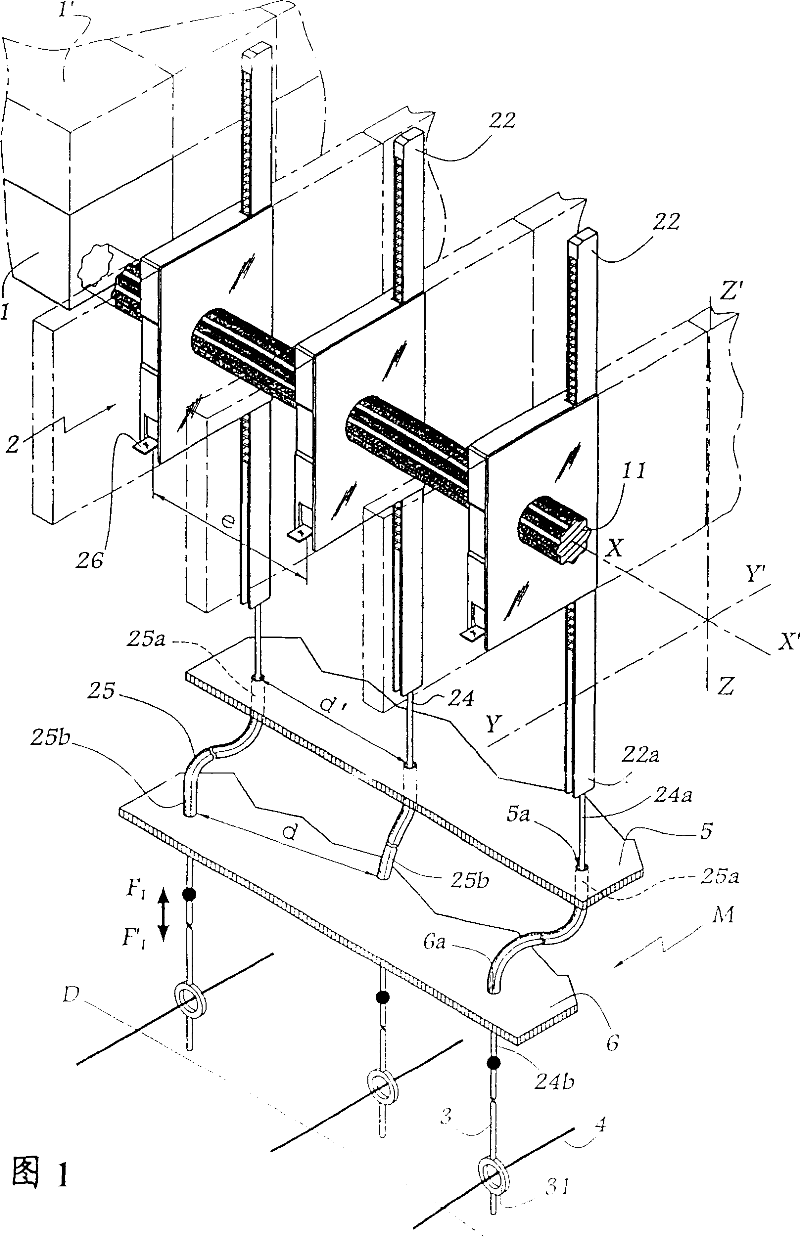

[0026] The electric rotary actuator 1 shown in FIG. 1 is a servo motor with a splined output shaft 11, and X-X' represents the longitudinal geometric axis of the output shaft 11. The axis is parallel to the direction D of the weft of the loom.

[0027] Other actuators 1'of the same type are arranged near the actuator 1. These actuators 1'are shown in dashed-dotted lines in FIG. 1, and their output shafts (not shown) are parallel to the shaft 11. .

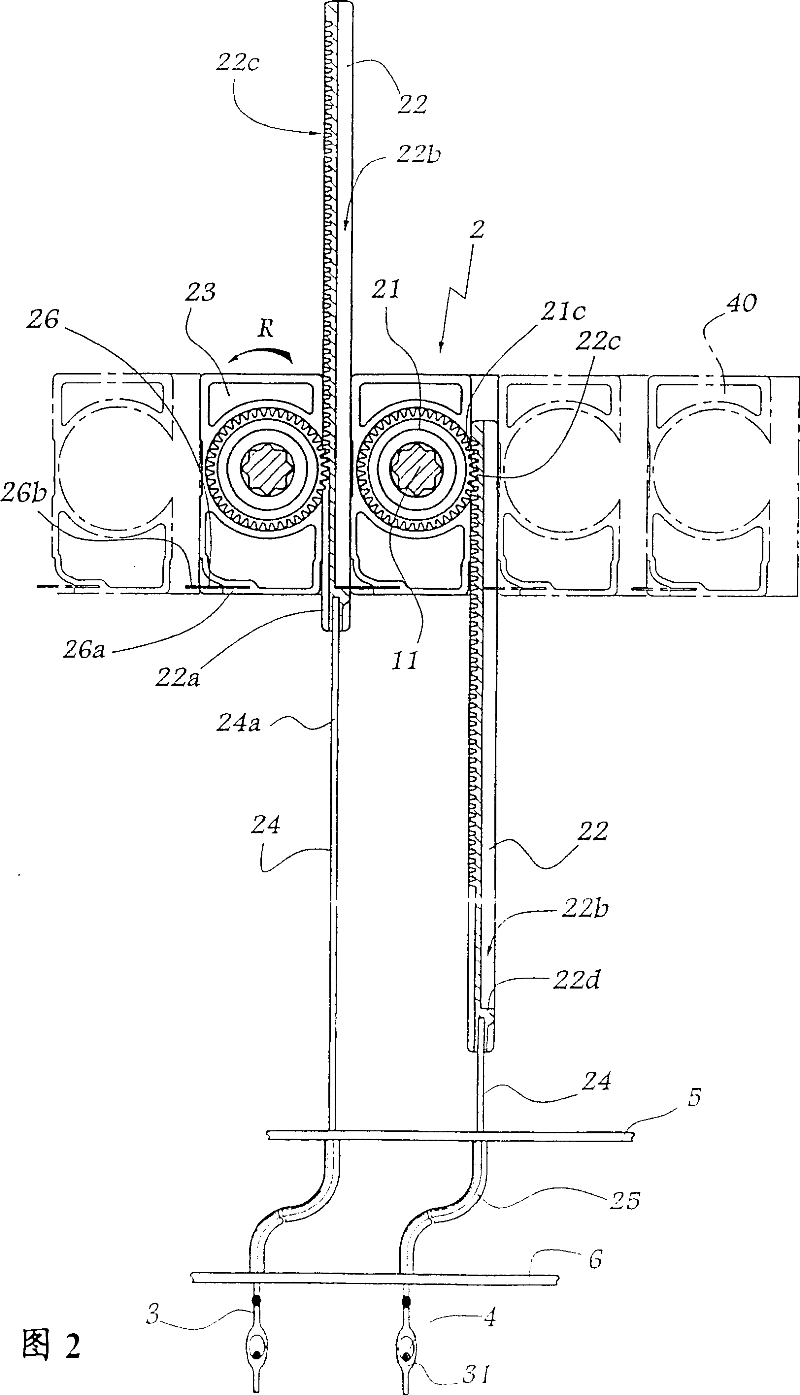

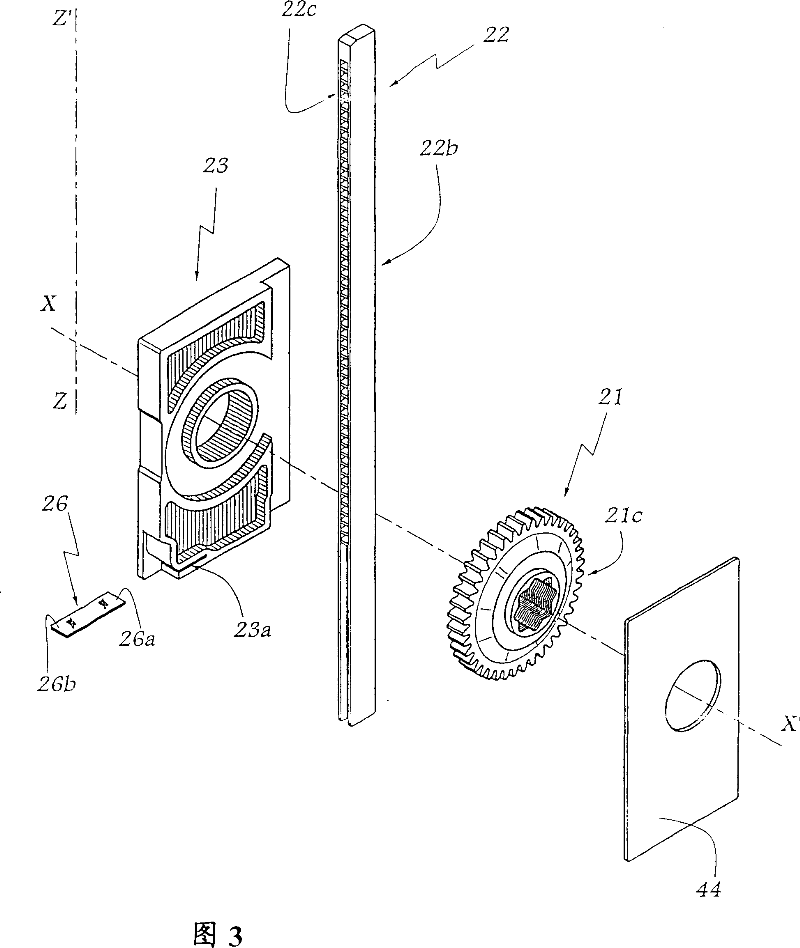

[0028] A plurality of identical modules 2 are installed on the shaft 11. Each module 2 includes a pinion gear 21 arranged around the shaft 11 and having a central opening, which allows the pinion gear to cooperate with the spline of the shaft. It is driven to rotate around the axis X-X'. The module 2 can slide on the corresponding shaft 11 with a reduced gap. Each module 2 also includes a straight rack 22 substantially parallel to an axis Z-Z' inclined with respect to the horizontal direction when the loom M is in the normal use config...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com