Method for manufacturing light weight ceramics

A technology of lightweight ceramics and manufacturing methods, applied in the direction of manufacturing tools, ceramic molding machines, etc., can solve problems such as heavy weight, reduced scope of application, and inability to break through

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to make your examiner clear about the content of the present invention and its overall operation mode, it is described as follows with the help of drawings:

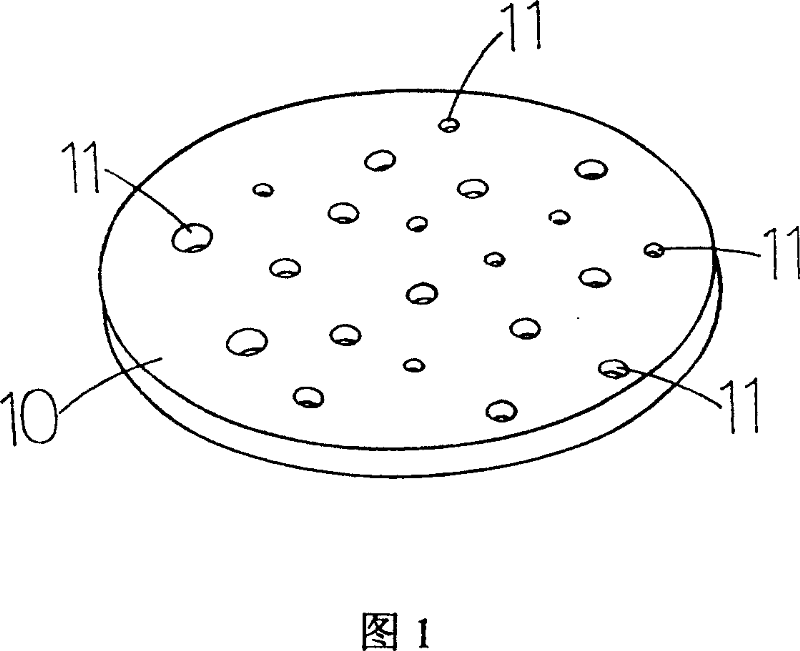

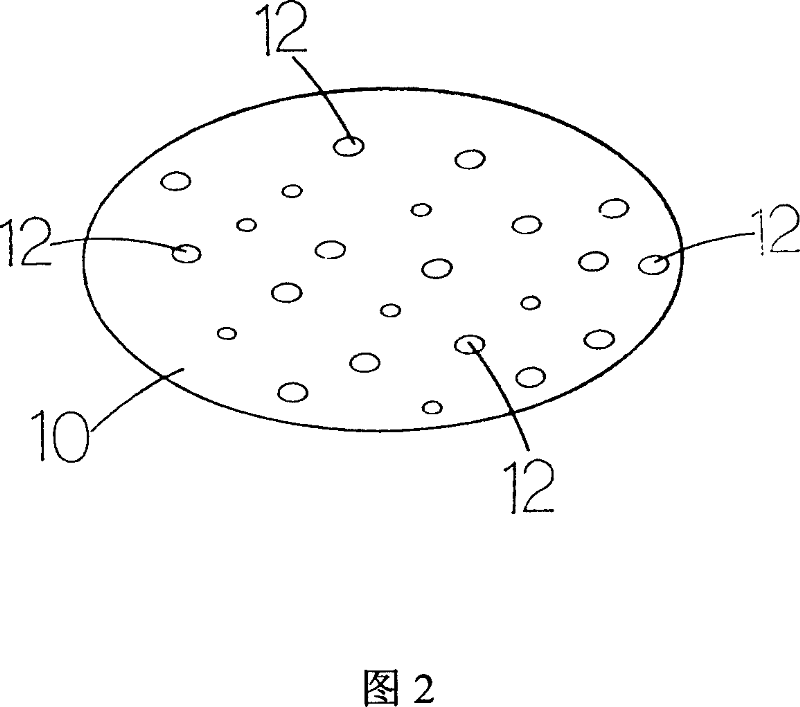

[0033] The present invention "a manufacturing method of lightweight ceramics" is mainly used to manufacture ceramic finished products 10 as shown in Figures 1 and 2, wherein the surface of the ceramic finished product 10 is densely covered with open pores 11 in the form of channels, The inside is densely covered with closed air holes 12 , and the overall ceramic product 10 has the characteristics of light weight, heat insulation, fire prevention and waterproof due to the formation of closed air holes 12 .

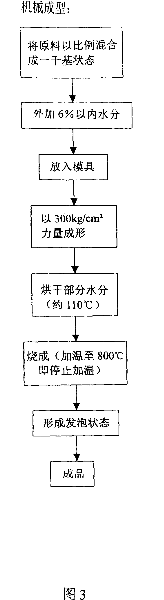

[0034] As for the overall manufacturing process of the present invention "a method for manufacturing a lightweight pottery urn" as shown in Figure 3 and Figure 4, the raw material ratios are as follows:

[0035] a. When the powdered glass frit is low temperature type:

[0036] ①Powdered glass frit (pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com