Bidirectional thermal expansion valve

A thermal expansion valve, valve body technology, applied in the direction of lift valve, valve details, valve device, etc., can solve the problems of high failure rate, poor sealing performance, small cooling (heat) capacity, etc., achieve good sealing performance, improve sealing Good performance and sealing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

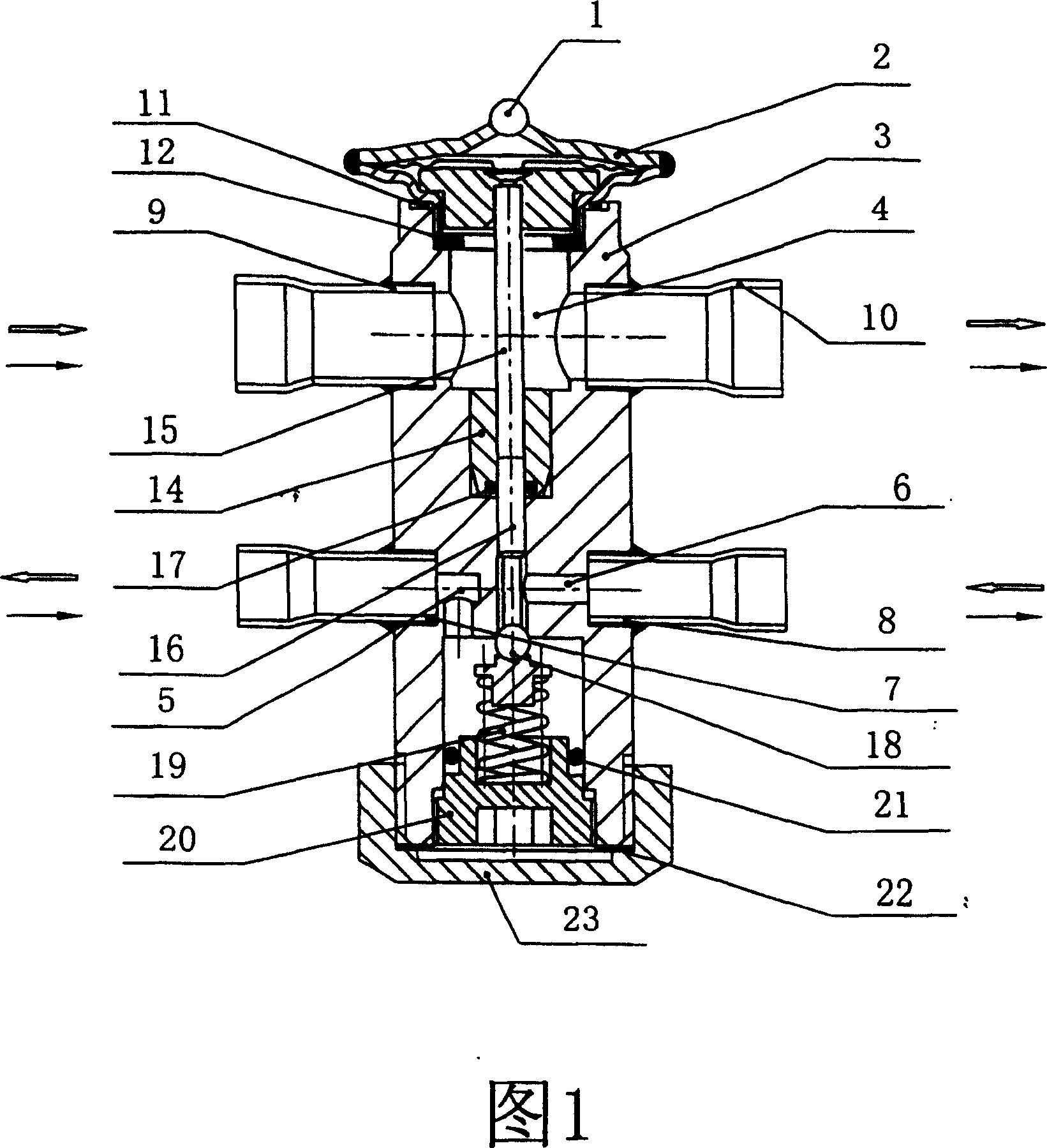

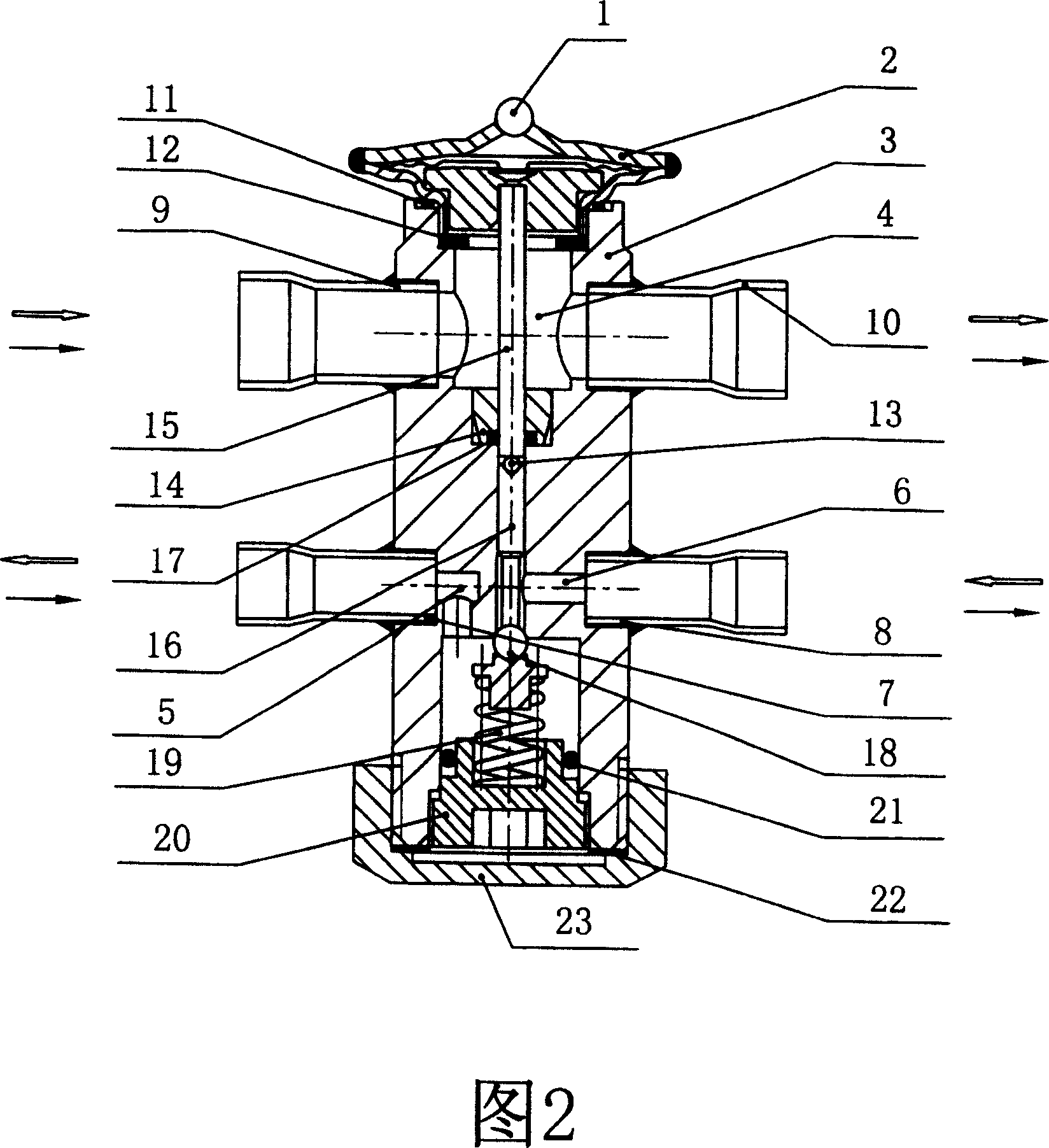

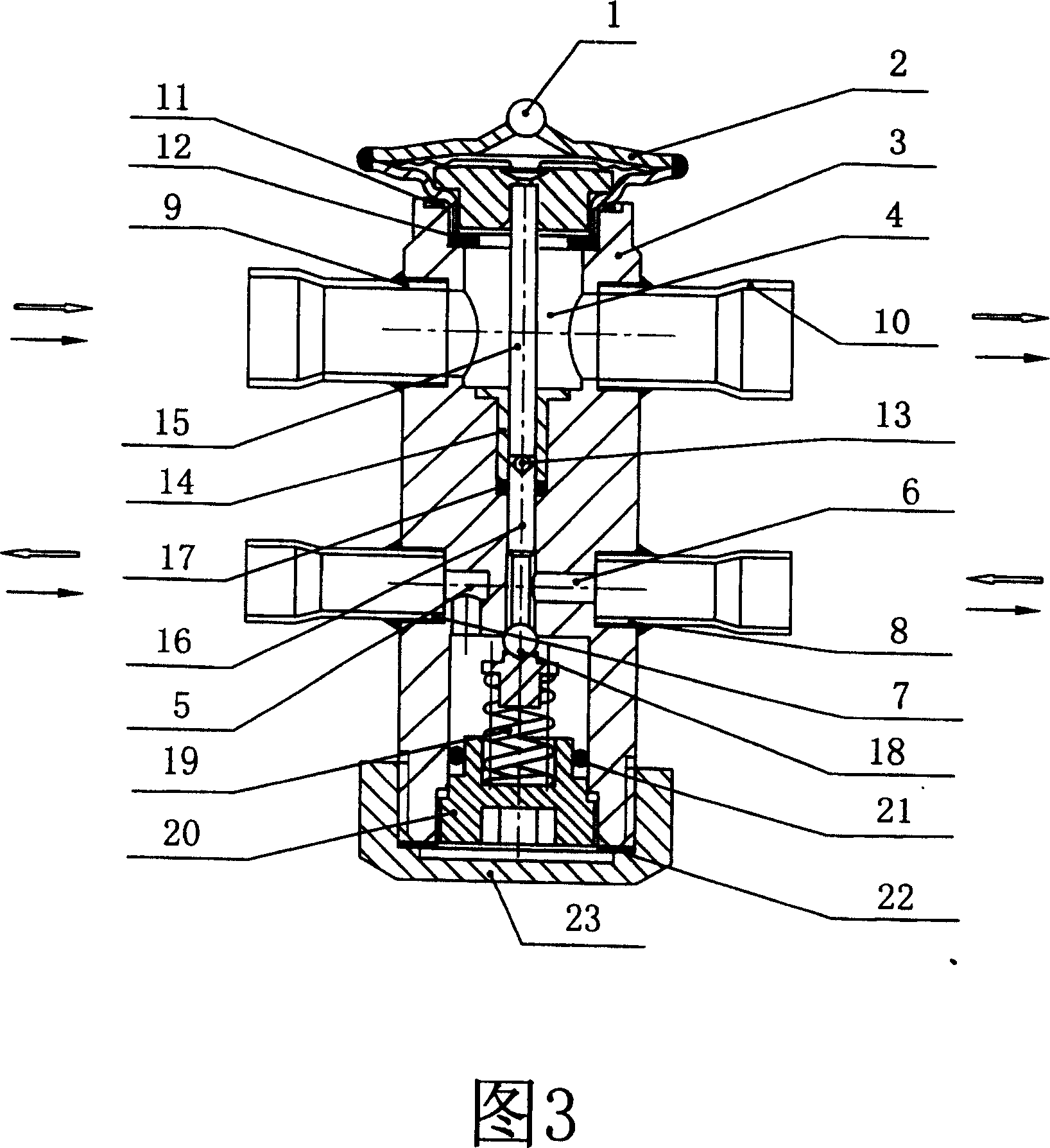

[0021] The present invention mainly consists of a valve body 3 with a membrane box 2 and a gas return passage 4 at the upper end, an air inlet and return pipe 9 and an air return pipe 10 placed at the left and right ends of the air return passage 4, and a liquid inlet pipe 7 placed at the lower part of the valve body 3. The liquid inlet hole 5, the liquid outlet hole 6 with the liquid outlet pipe 8, the valve core 18 placed between the liquid inlet hole 5 and the liquid outlet hole 6, and the balance spring 19 with the adjustment screw 20 placed at the bottom of the valve core 18 , the transmission rod 15, the centering steel ball 13, and the valve needle 16 placed between the bellows 2 and the valve core 18, the positioning block 14 with the rubber sealing ring 17 of the balance part embedded in the bottom of the return air passage 4 of the valve body 3 , The seal nut 23 placed at the bottom of the valve body 3 etc. constitutes.

[0022] Accompanying drawing 1, 2, 3, 4, 5, 6 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com