Improved method for etching vias

An etching and substrate technology, which is applied in the field of plasma processing, can solve the problems such as the serious impact of 150mm substrate, and achieve the effects of reducing residence time, reducing the formation of columns, and eliminating the formation of columns

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

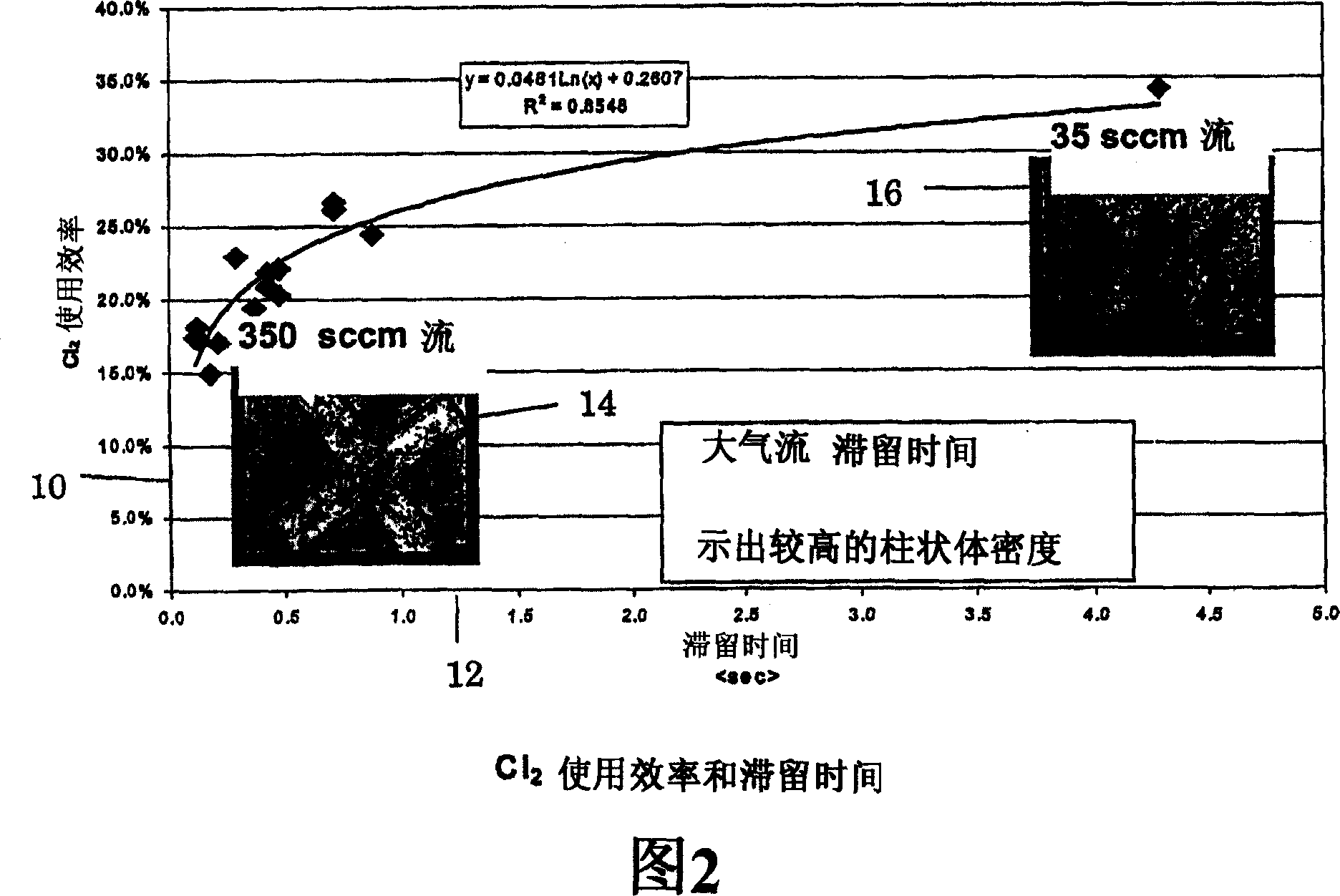

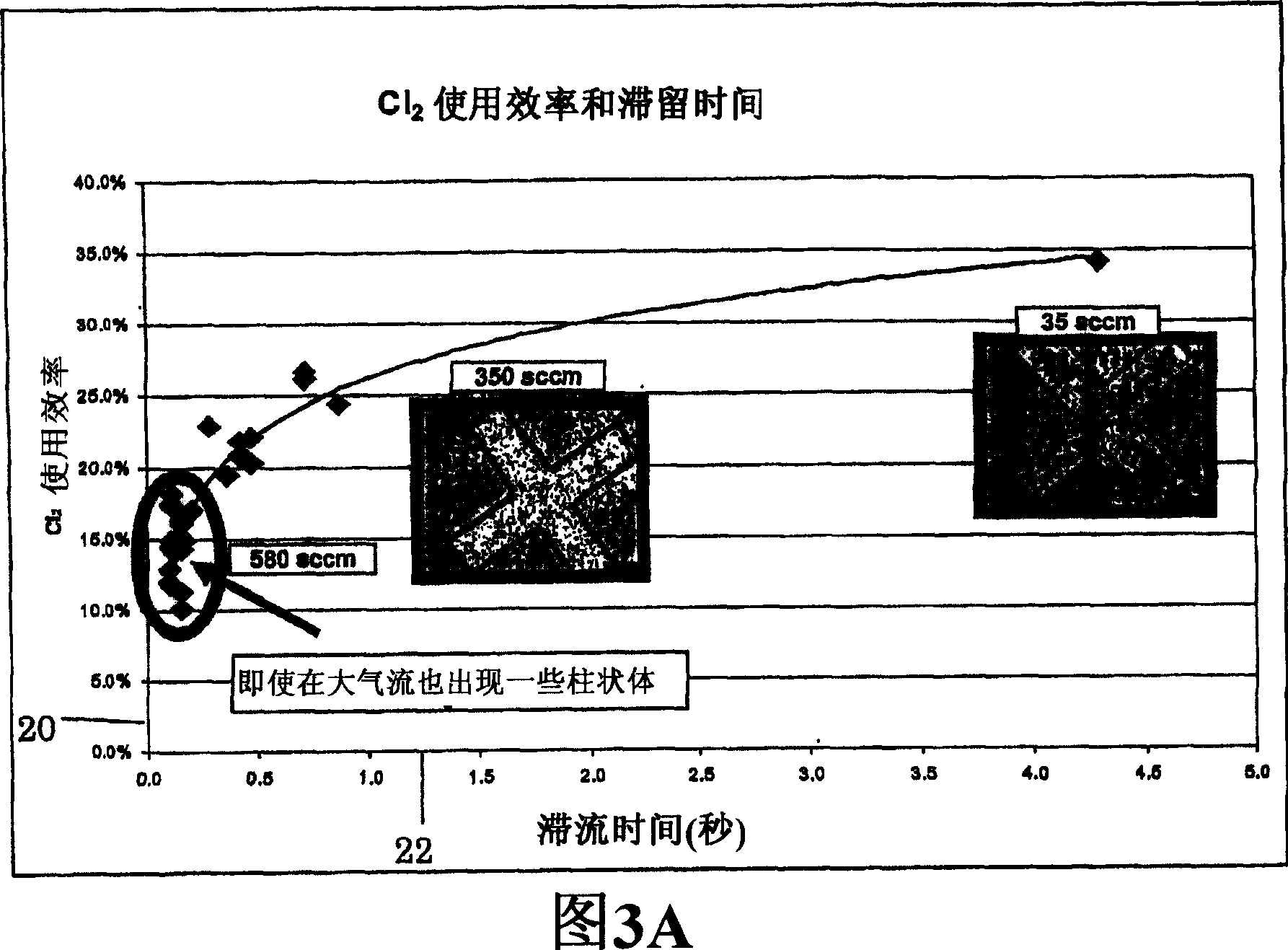

[0034] Preferred embodiments of the present invention are directed to a method utilizing high-speed Cl 2 Gas flow (short dwell time), high inductively coupled plasma (ICP) power, ICP confinement ring, low RF bias etch initiation and RF jump to etch GaAs vias. Discussed in more detail below, these process modifications result in a high-speed (>6 μm / min) via etch process that eliminates pillars. In addition, a sloped via profile is obtained by etching a sloped photoresist mask.

[0035] Dry etching of GaAs vias requires etching relatively deep (~100 μm) features into the thinned GaAs substrate, terminating on a metal etch stop layer (typically gold). As shown in Table 1, due to the relatively high volatility of the etch products, dry etch processes are typically chlorine-based (i.e., BCl 3 / Cl 2 , Ar / Cl 2 , SiCl 4 / Cl 2 Wait). Although fluorine plasma does not chemically corrode GaAs, it can also contain a small amount of precursor (CF 4 etc.) Fluorine is added to the tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com