Integrated cleanable burning plate for gas stove

A technology of integral combustion disc, which is applied in the field of integral cleaning combustion discs for gas stoves, can solve problems such as complex burner structure, difficult to clean nozzles, complex burner structure, etc., to achieve increased gas combustion effect, uniform firepower distribution, The effect of lowering the temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

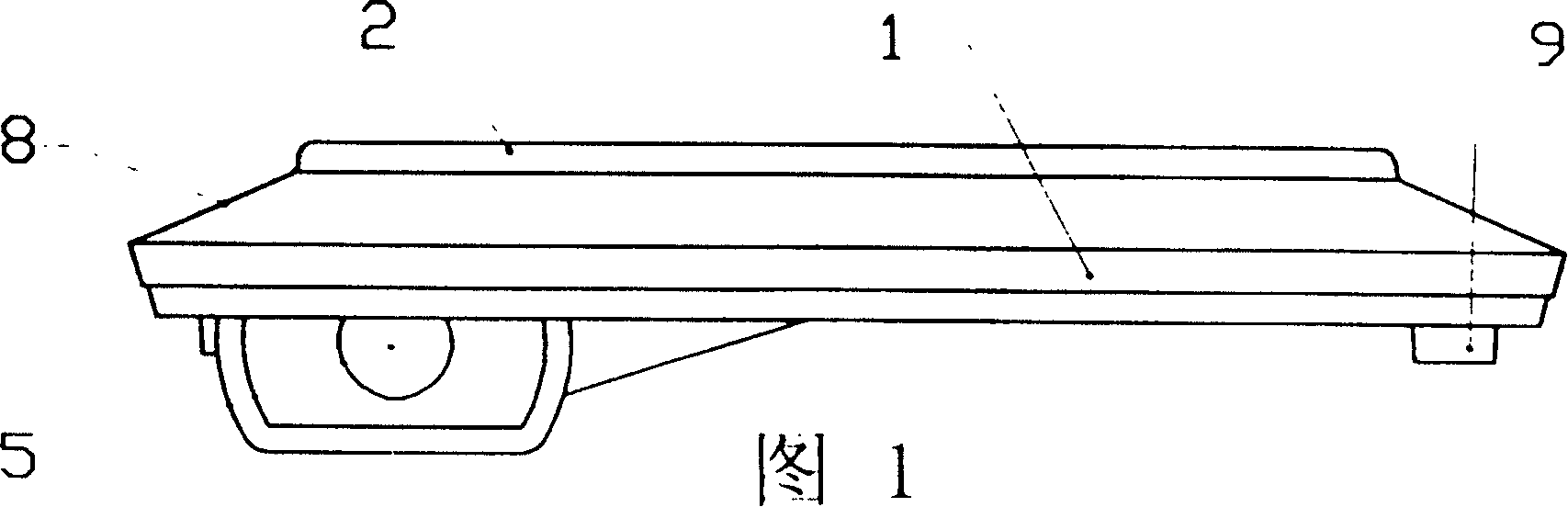

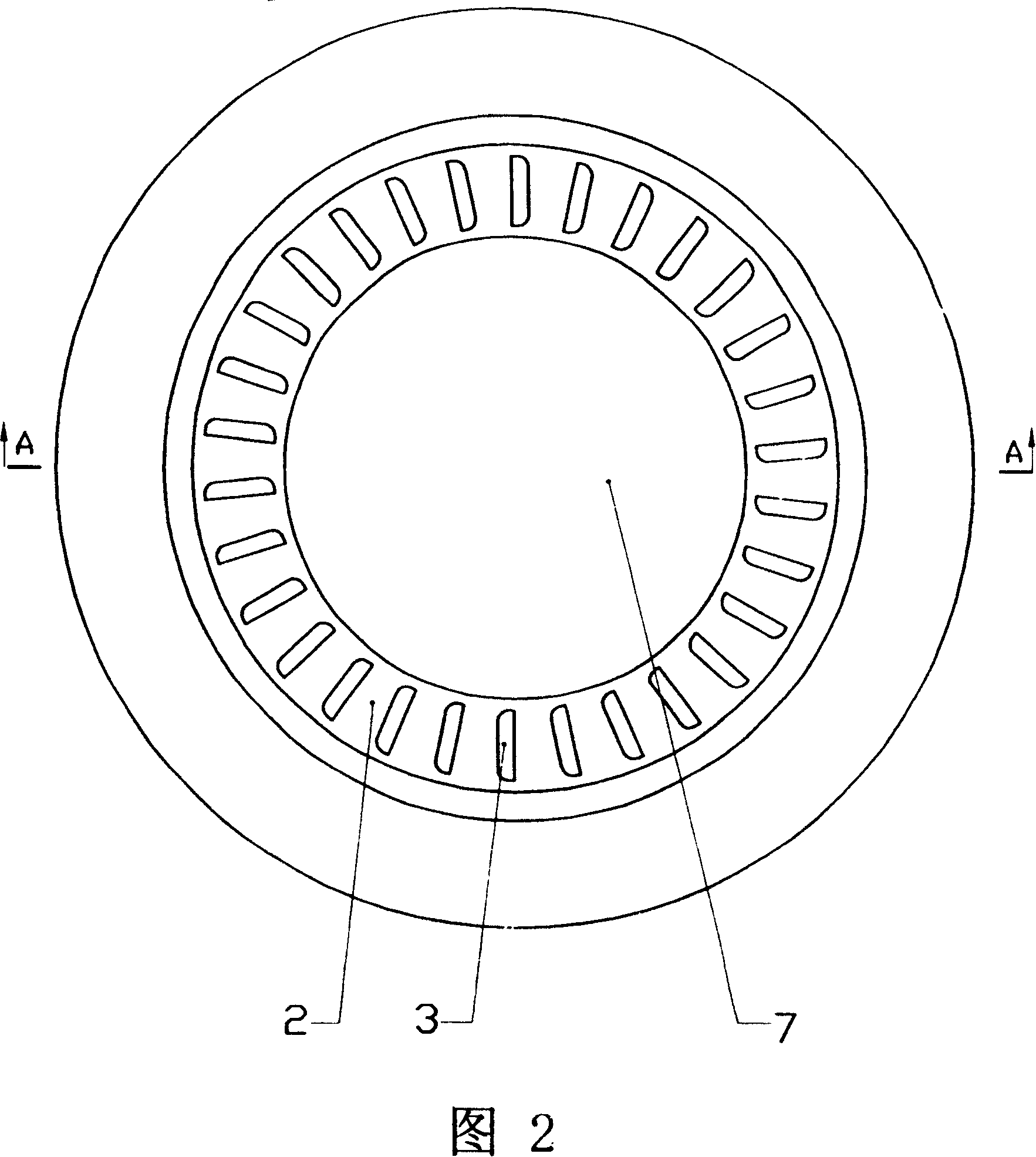

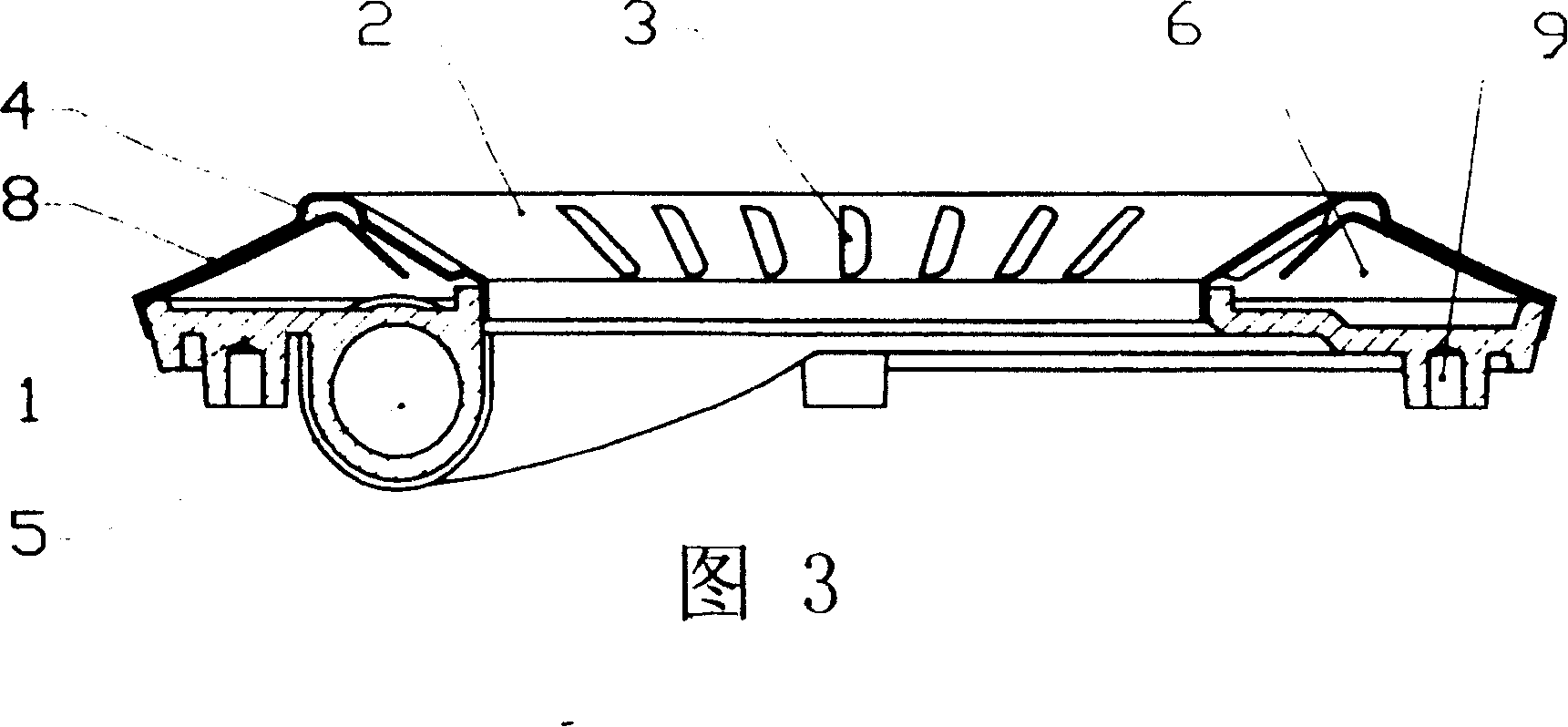

[0027] Embodiment 1, see Fig. 1, Fig. 2, Fig. 3. Fire outlet cover 2 is to form fire outlet cover with stamping processing of stainless steel plate, and it comprises the conical fire cover of band fire hole 3 and decorative slope 8, and decoration slope 8 is to extend outwards downwards by the tapered fire cover upper end of band fire hole and form. The structure of the disc body 1 is as described above. The fire outlet cover 2 is covered on the disc body 1. In order to make the gas mixing and distribution more uniform, a gas equalizing plate 4 is installed in the mixing cavity 6 formed by the fire outlet cover 2 and the disc body 1. The fire hole 3 is an elongated slit formed by stamping, which constitutes a swirl slit integral type cleaning burning disc.

Embodiment 2

[0028] Embodiment 2, the fire outlet cover 2, the decorative slope 8 and the disc body 1 are divided into three parts and manufactured (see Fig. 4), the fire outlet cover 2 is a conical ring cover, and its bottom is inserted on the inner wall of the disc body 1, and its top is passed through The decorative slope 8 is connected to the outer wall of the disc body 1 . The fire hole 3 is a point fire hole. A gas mixing cavity 6 is arranged after the fire outlet cover 2, the decorative slope 8 and the chassis of the disc body 1 are assembled. The structure of the disc body 1 is as described above.

Embodiment 3

[0029] In Embodiment 3, the disc body 1 includes a decorative slope 8, and the rest of the structure is the same as that described above, see FIG. 5 . Fire outlet cover 2 is a conical ring cover. The lower end of the fire outlet cover 2 is inserted on the inwall of the disc body 1, and the upper end is mounted on the decorative slope of the disc body, and the fire hole 3 of the fire outlet cover is a point fire hole. There is a gas mixing cavity 6 after the fire outlet cover 2 and the disc body 1 are closed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com