Fibre detaching apparatus with high shearing

A fiber dissociation, high shear technology, applied in the field of fiber disintegrators, can solve the problems of affecting process operation, reducing the content of fiber bundles or fiber fragments, low smoothness, etc., to achieve high surface smoothness, improve physical properties, and surface texture. delicate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

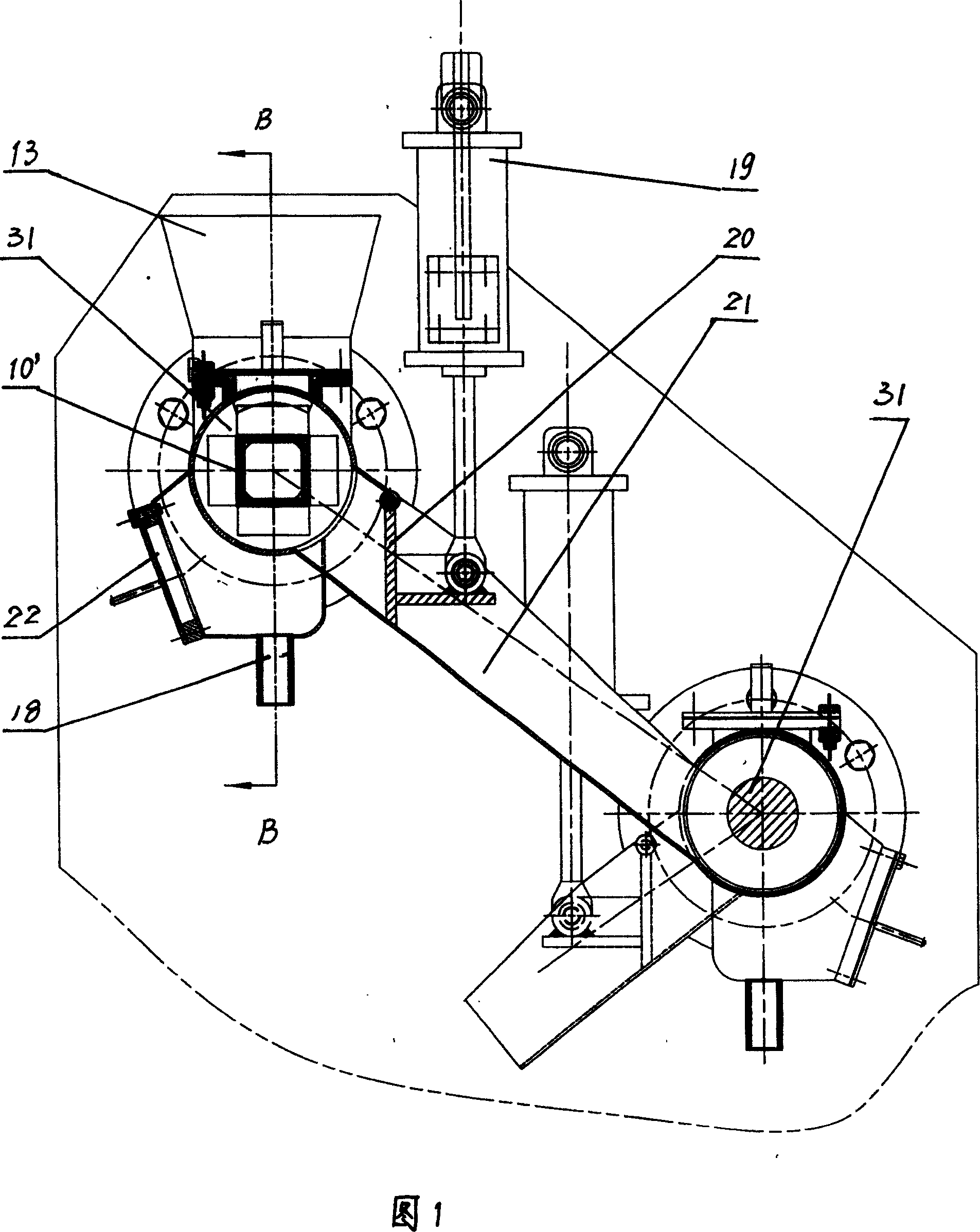

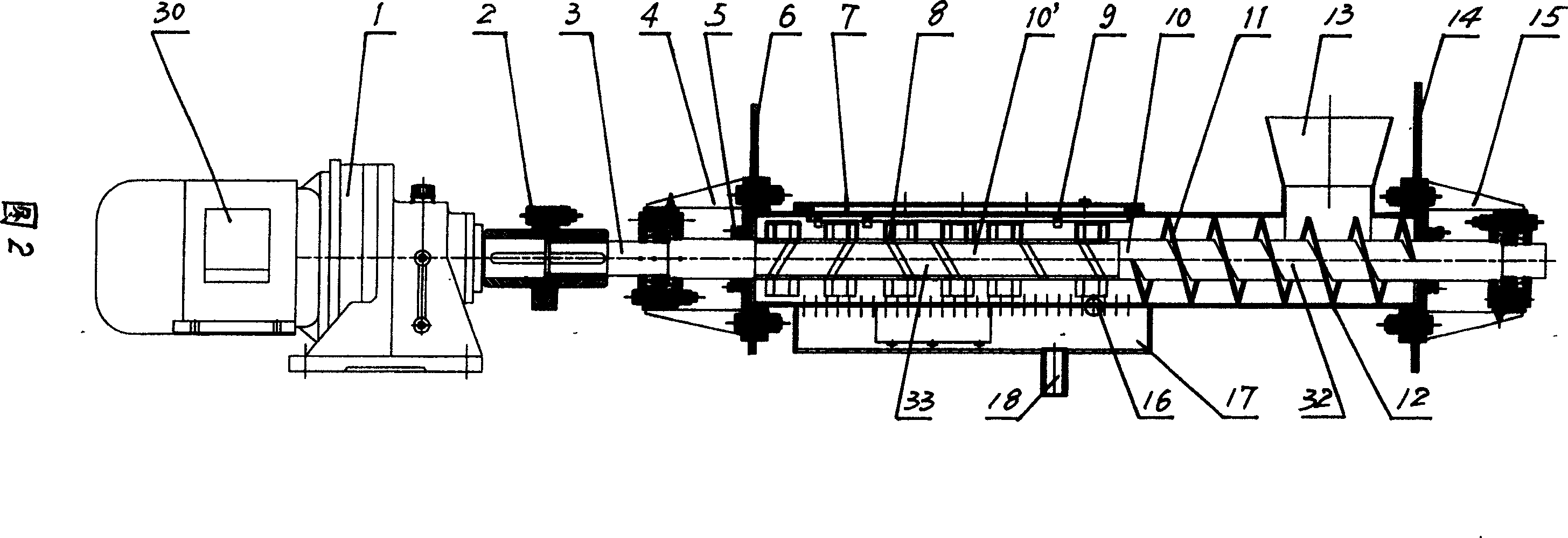

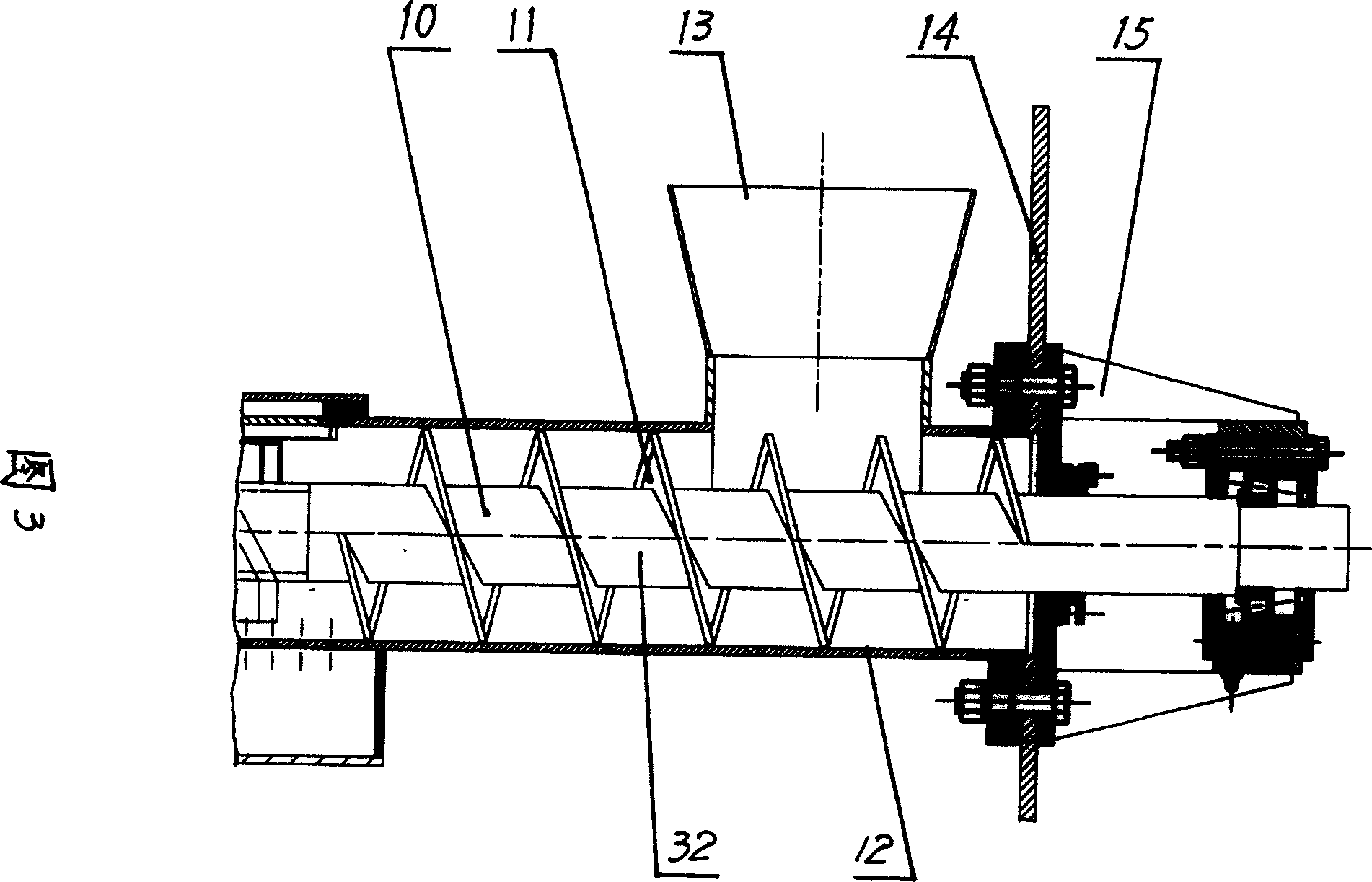

[0023] The high-shear fiber dissociation machine of the present invention will be described in further detail below with reference to the accompanying drawings.

[0024] As shown in Figures 1 to 5, the structure of the high-shear fiber disintegrator of the present invention is composed of frames 6 and 14, a power unit 30, a cylinder 12 and a multi-stage operating unit connected in sequence; the power unit 30 includes Speed-adjusting motor and reduction box 1; the multi-stage operation unit may include a 2-stage or 3-stage operation unit 31, and each stage of the operation unit 31 includes a spiral conveying area 32 and a main working area 33 arranged in the cylinder 12 The spiral conveying area 32 includes an equal-pitch spiral blade 11 on the spiral shaft 10, one end of the spiral blade 11 is connected to the main working area 33, and its main function is to treat the pulp (concentration of 8-30%) Disperse and evenly transport to the main work area 33. The screw shaft head 3 at t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com