Piezoelectric type microdroplet sprayer with membrane

A spray device, piezoelectric technology, applied in printing and other directions, can solve the problems of limited compression effect of piezoelectric elements, inability to generate high pressure, fluid particles are not easy to micronize, etc., to avoid corrosive fluid damage, wide application range, The effect of increasing the fluid compression pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

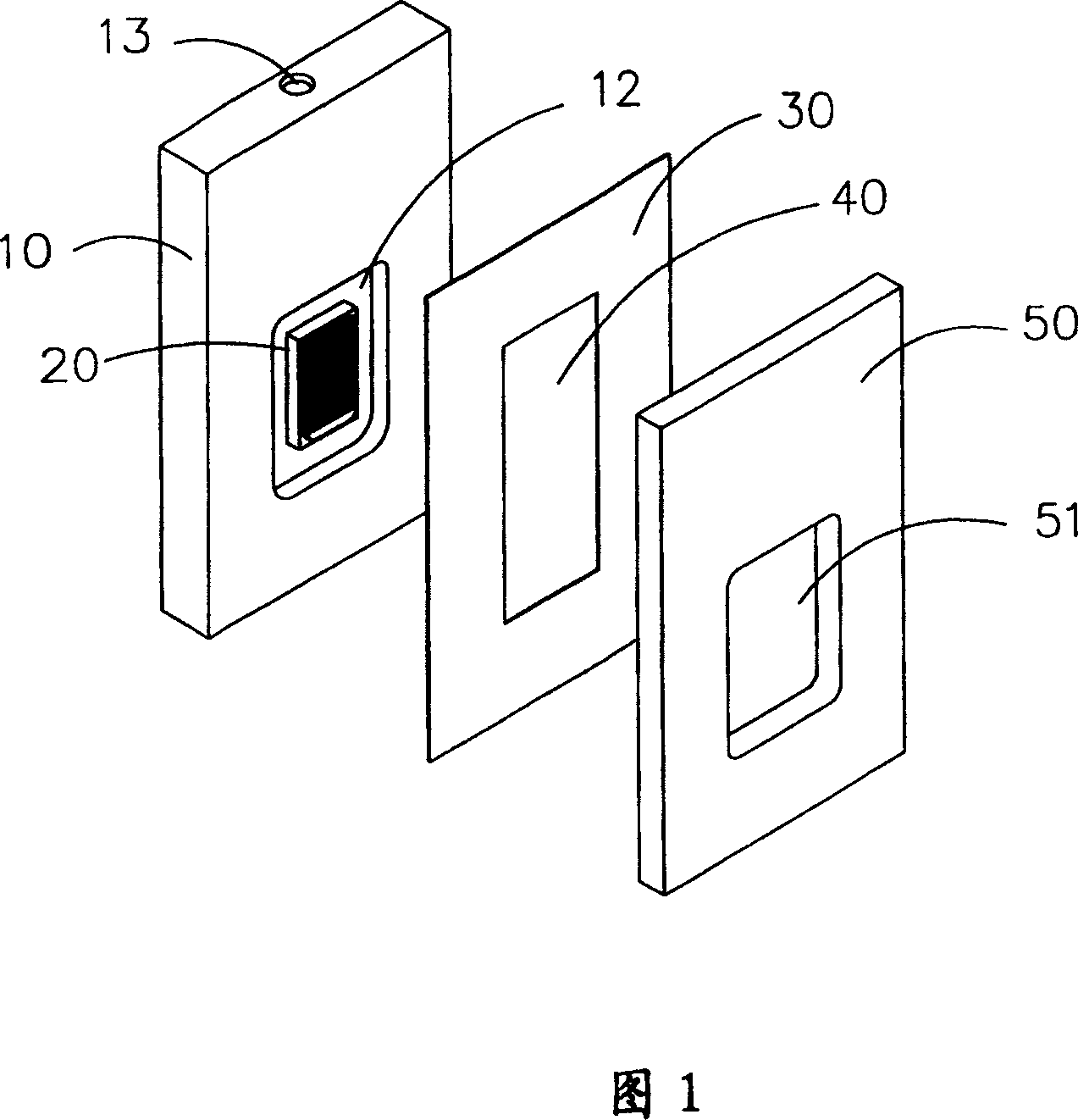

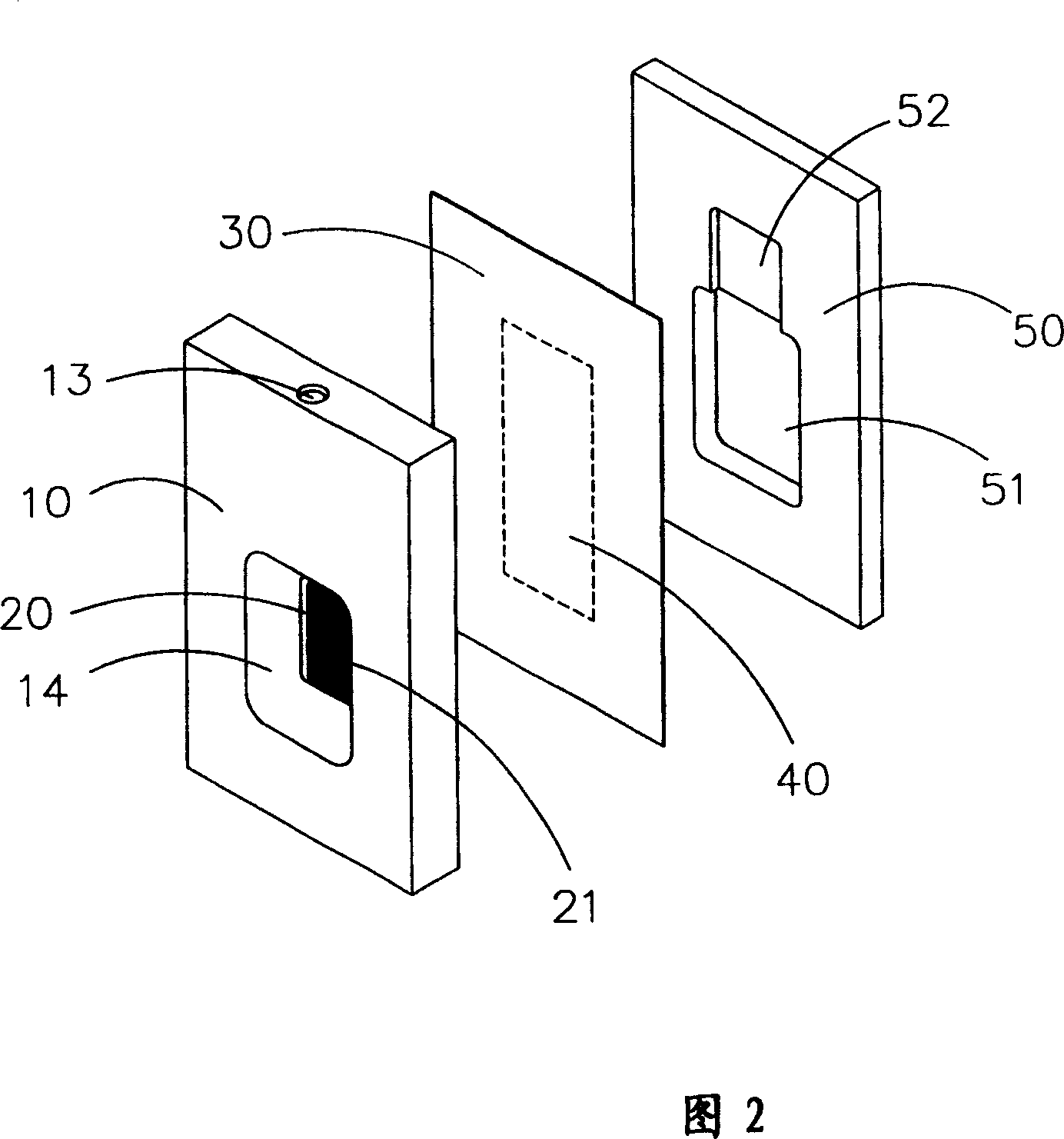

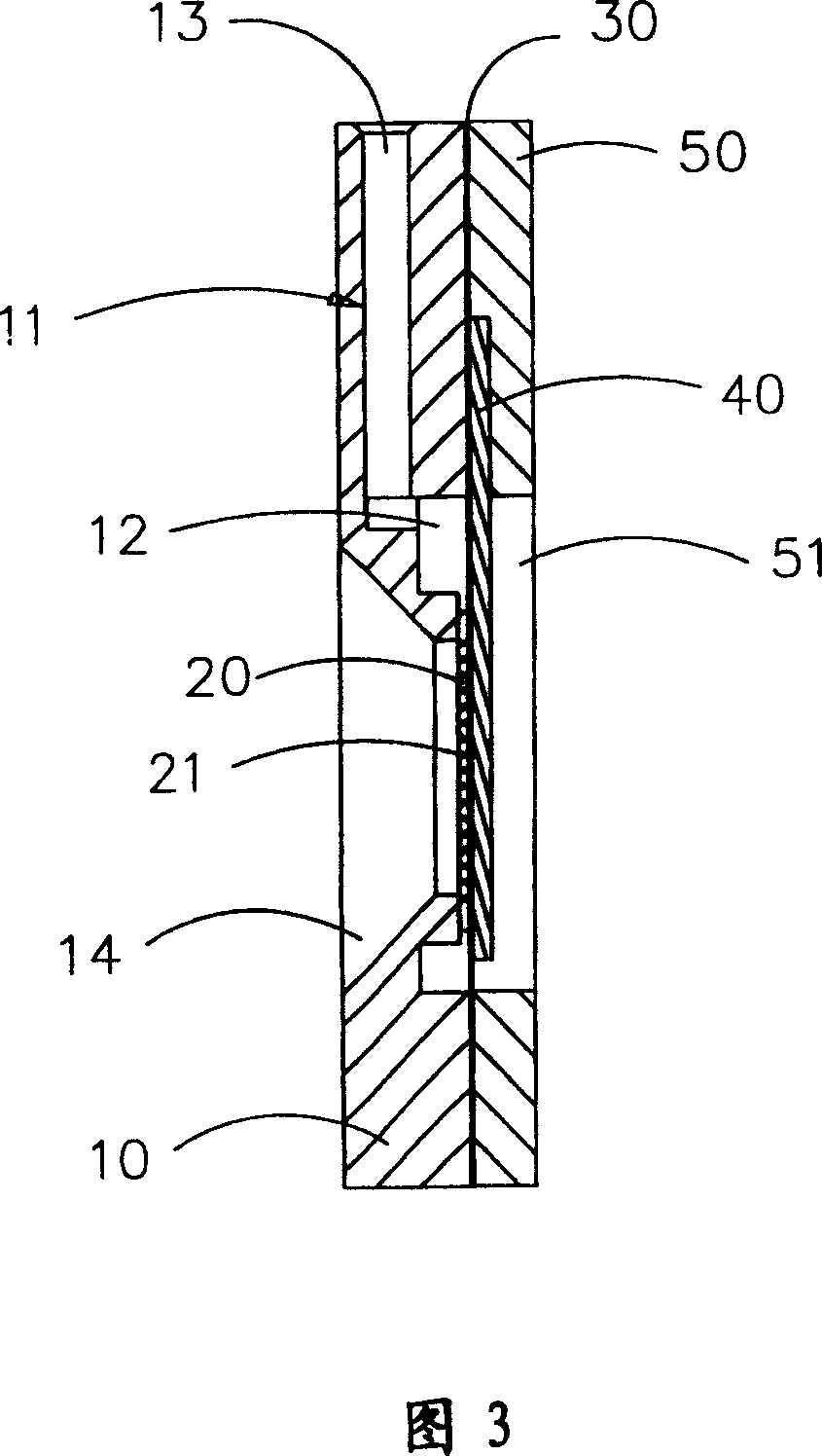

[0026] As shown in FIGS. 1 and 2 , the present invention includes an orifice seat 10 , an orifice plate 20 , a diaphragm 30 , a piezoelectric plate 40 and a piezoelectric plate holder 50 .

[0027] The nozzle hole seat 10 is provided with an installation hole 14 for the nozzle hole plate 20 to be installed in the installation hole 14 . On the nozzle hole seat 10, a fluid passage 11 is provided, and the fluid passage 11 includes a cavity 12 surrounding the surrounding area of the nozzle hole plate 20 and an inlet channel 13 connected from the cavity 12 to the outside of the nozzle hole seat 10. The flow channel 13 can guide the fluid from the outside of the nozzle hole seat 10 into the cavity 12 , and allow the fluid to enter the gap between the nozzle hole plate 20 and the diaphragm 30 from around the nozzle hole plate 20 .

[0028] The orifice plate 20 is a flat plate, on which several tiny orifices 21 are arranged densely, for the fluid to be sprayed out from the orifices ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com