End-clearance-free piston ring provided with positioning groove

A piston ring, no end gap technology, applied in the field of piston rings, can solve the problems of increasing fuel consumption, reducing the compression pressure of internal combustion engines, reducing the power of internal combustion engines, etc., and achieving the effects of reducing emissions, reducing emissions, and improving power.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

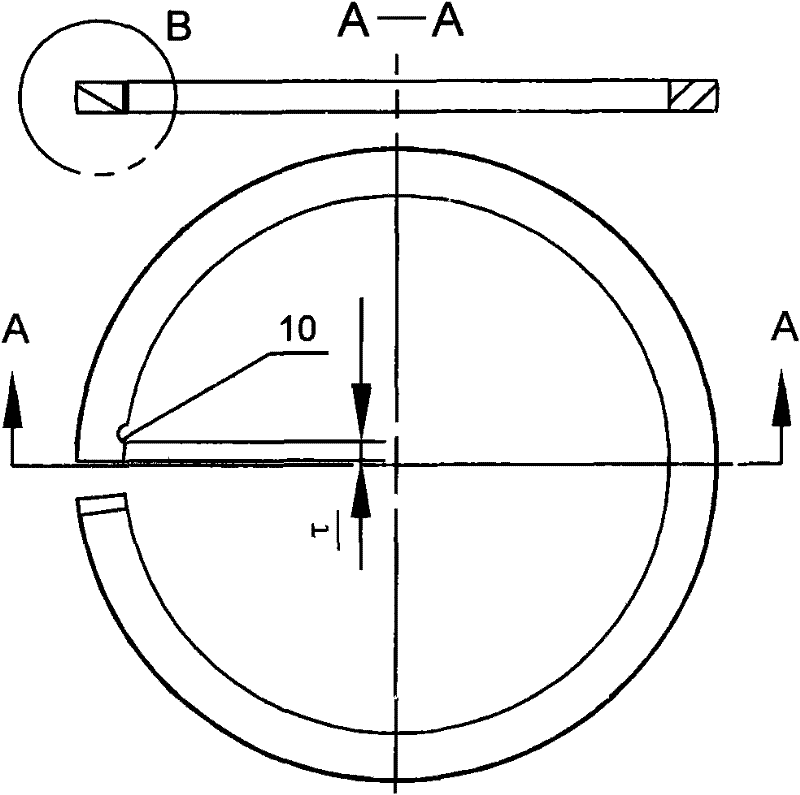

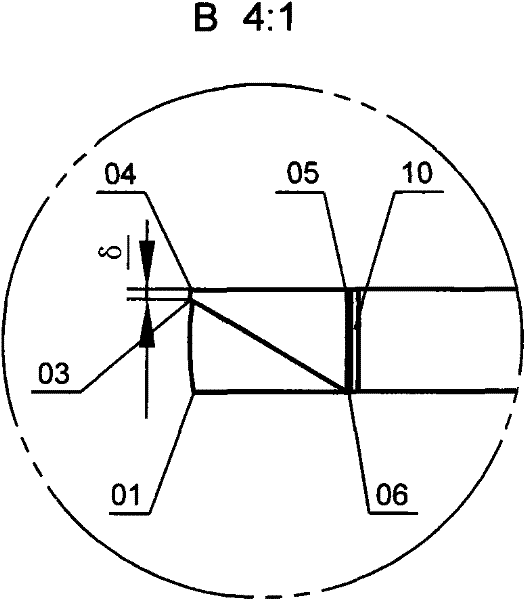

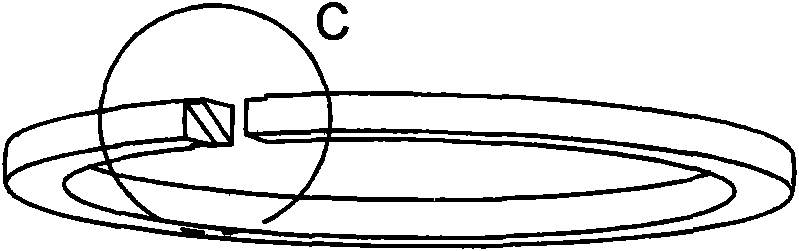

[0025] figure 1 , figure 2 , Figure 13 , Figure 14 , Figure 15 and Figure 16 The comparison shows that the piston ring changes from the natural state to the working state where the opening is closed by being placed in the cylinder or in the ring gauge. End-to-end lap length for fully sealed diagonal cutouts for backlash-free piston rings shown T , the expansion gap required for heating s , the distance between the cylindrical surface of the piston ring and its end surface τ Establish a small circular arc positioning groove 10, or at the other end from its end face τ Establish a small circular arc positioning groove 10 such as Figure 18 shown. Section line I-I symmetrically passes through the lap length T and piston ring shaft. lap length T Add expansion gap s is the dimension from the shoulder face to the boss face of the end face. Such as figure 2 , Figure 14 The diagonal line shown is a small distance from point 04 along the projected line of the ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com