Impact resistant compact cable

A cable and post-impact technology, applied in the field of cables, which can solve problems such as limiting elastic recovery of elastic materials, shape and size constraints of insulating layers, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

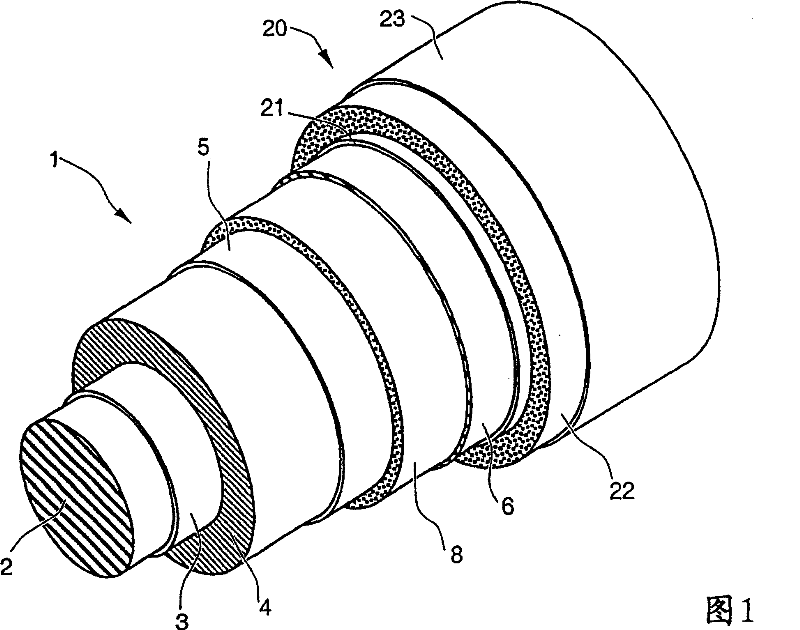

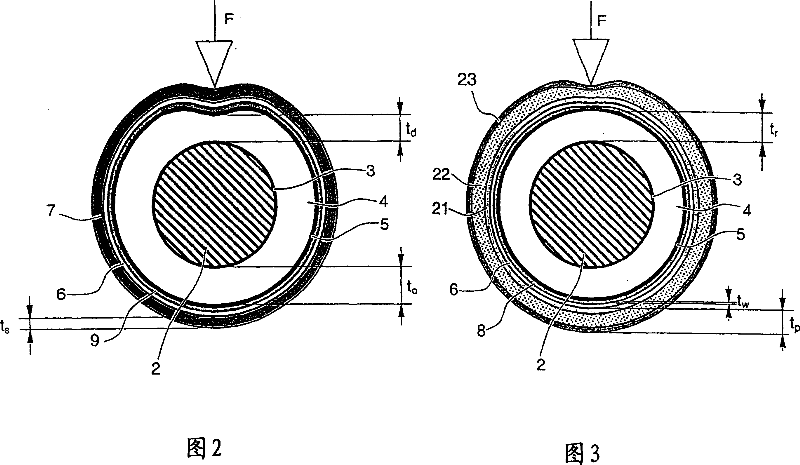

[0087] Figure 1 shows a perspective view of a partial cross-section of a cable 1 according to the invention which is typically designed for use in the medium or high voltage range.

[0088] Here, the type of power transmission cable described is typically operated at a nominal frequency of 50 Hz or 60 Hz.

[0089] The cable 1 includes: a conductor 2 ; an inner semiconductive layer 3 ; an insulating layer 4 ; an outer semiconductive layer 5 ; a metal cover 6 ; and a protection unit 20 .

[0090] Preferably, the conductor 2 is a metal strip, preferably made of copper or aluminium. Alternatively, the conductor 2 comprises at least two wires, preferably copper or aluminum, twisted together according to conventional techniques.

[0091] The determination of the cross-sectional area of the conductor 2 is related to the electric energy to be transmitted under the selected voltage. The cable according to the invention preferably has a cross-sectional area in the range of 16 to 100...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com