Six-phase permanent-magnet generator of automobile

A permanent magnet generator, six-phase technology, applied to synchronous motors with static armatures and rotating magnets, magnetic circuit rotating parts, magnetic circuit shape/style/structure, etc. The structure of the magnetic generator is complex and other problems, so as to achieve the effect of less reactive power loss, compact structure and more phases.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

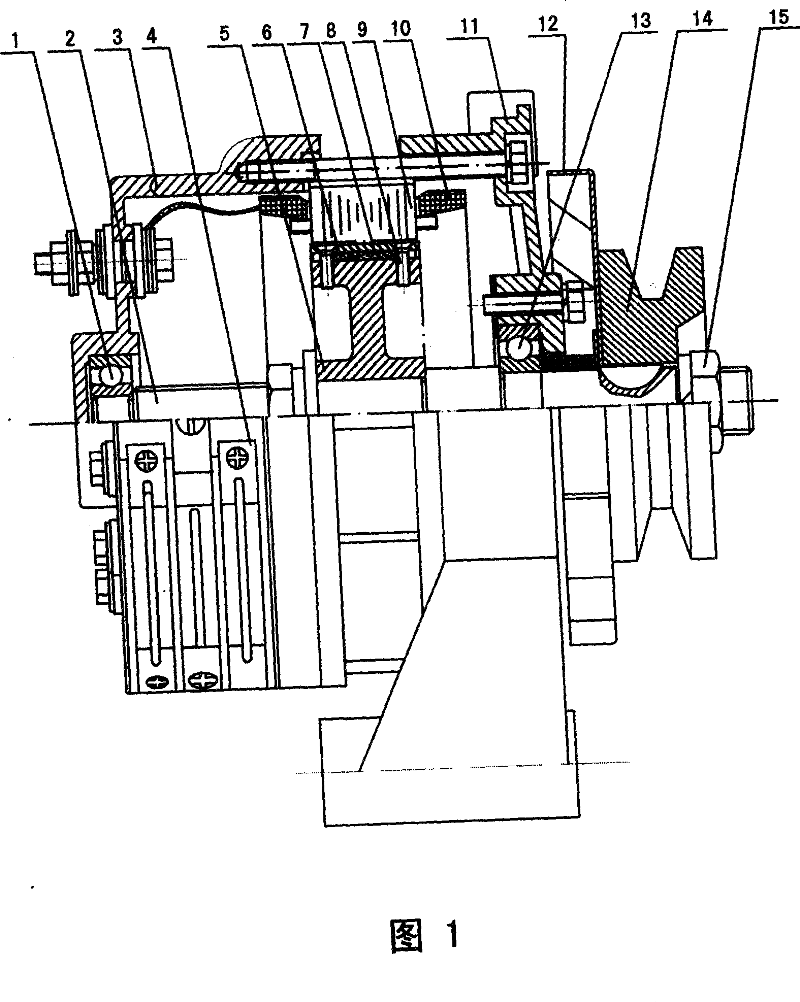

[0008] 1. Rear end bearing 2. Rotating shaft 3. Rear end cover 4. Six-phase half-wave controllable rectifier regulator 5. Rotor core 6. Permanent magnet 7. Pole shoe 8. Non-magnetic screw 9. Stator core 10 .Armature winding 11. Front cover 12. Fan 13. Front bearing 14. Pulley 15. Nut

[0009] The present invention will be further described below in conjunction with accompanying drawing:

[0010] Each phase of the armature windings 10 in the six identical phases of the armature windings 10 respectively crosses the six poles on the stator core 9 and inserts the wires sequentially. The phase difference of the above-mentioned armature windings 10 is 60°. The first end of the armature winding 10 is connected to the positive output end of the generator, and the tail ends of the above-mentioned armature windings 10 are respectively connected to the input end of the six-phase half-wave controllable rectifier regulator 4 to form a six-phase permanent magnet generator. Each permanent m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com