High strength and low extending thick Denier polypropylene yarns and production thereof

A production method and technology of polypropylene yarn, applied in the field of textile fiber processing, can solve the problem that polypropylene yarn cannot complete the processing of 3000-14000 d special ply network, achieve excellent mechanical properties and chemical resistance stability, increase output and reduce production costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

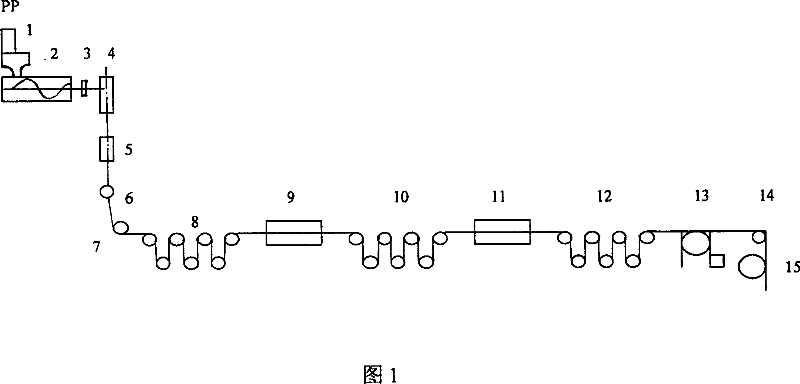

[0040] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0041]The polypropylene raw material of a certain specification is sucked into the hopper through the storage bin, melted by the screw extruder, the screw shell is electrically heated, and the melt enters the spinning box through pre-filtering. There are 12 spinning boxes, each with double spinnerets, each with a metering pump to control the metering. The spinneret is rectangular, and the spinning assembly is a bottom-loading type. The tow is cooled by side blowing, and the formed tow is oiled and sent to the first seven-roller drawing by the traction roller. The drawing rolls are heated by hot oil to preheat the tow to a certain temperature. The tow is uniformly heated to the stretching temperature by the hot air from the upper and lower directions in the first heating box, and each tow stretched by the second seven-roller is stretched and shaped in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| heat deflection temperature | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com