Refrigerator and vacuum thermal insulating material and producing method thereof

A technology of vacuum heat insulation material and manufacturing method, which is applied in the direction of chemical instruments and methods, heat exchange equipment, household refrigeration equipment, etc., can solve the problems of poor strength and sufficient progress, and achieve high strength, excellent heat insulation performance and effective use Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Hereinafter, several embodiments of the present invention will be described with reference to the drawings. In addition to domestic and commercial refrigeration-freezers, the so-called refrigerator of the present invention also includes: automatic vending machines, commodity display racks, commodity display cabinets, cold storage boxes, cold boxes, refrigeration-freezer cars and the like.

[0034] Next, a refrigerator and a vacuum insulation material according to a first embodiment of the present invention will be described with reference to FIGS. 1 to 7. FIG.

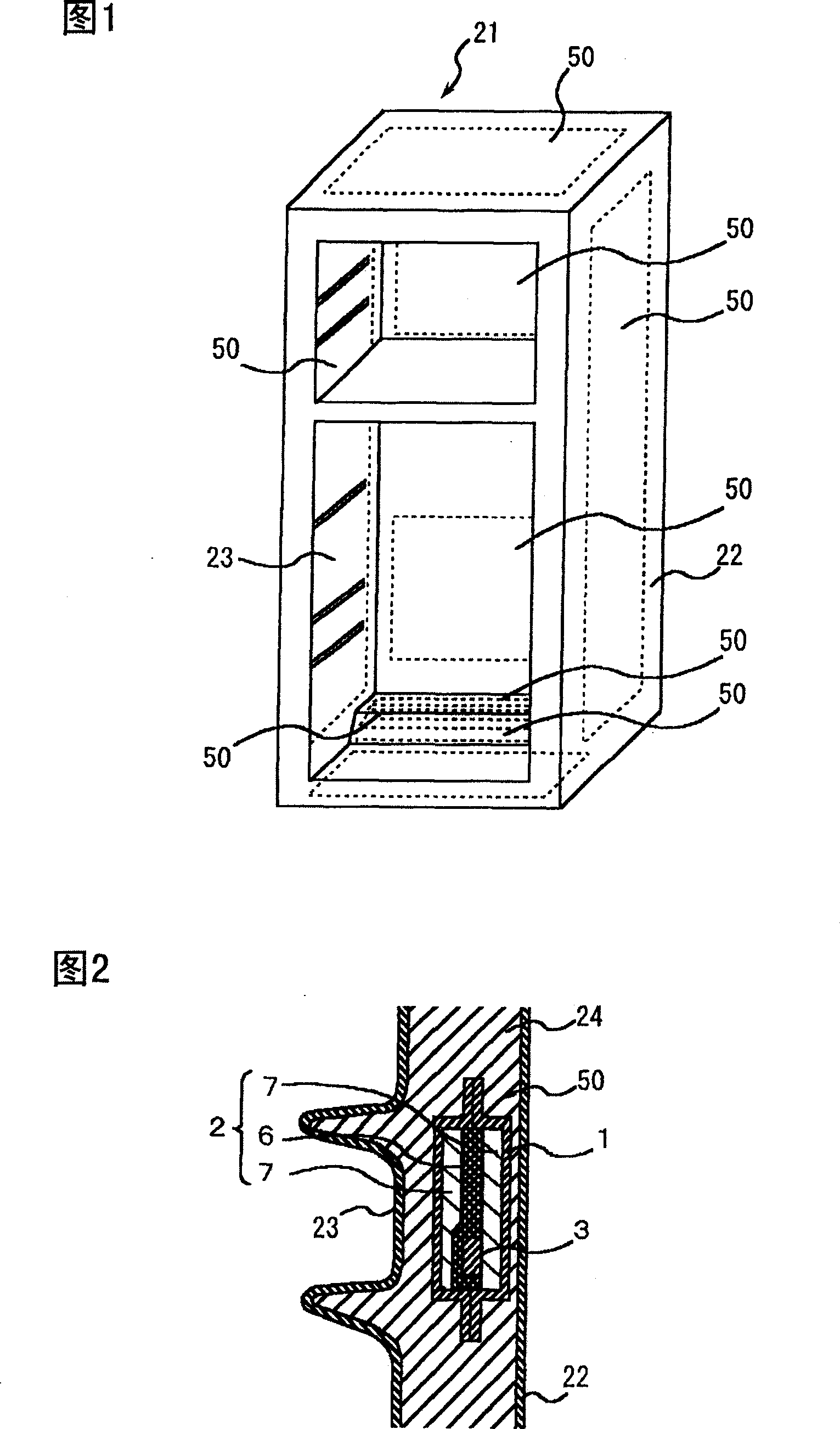

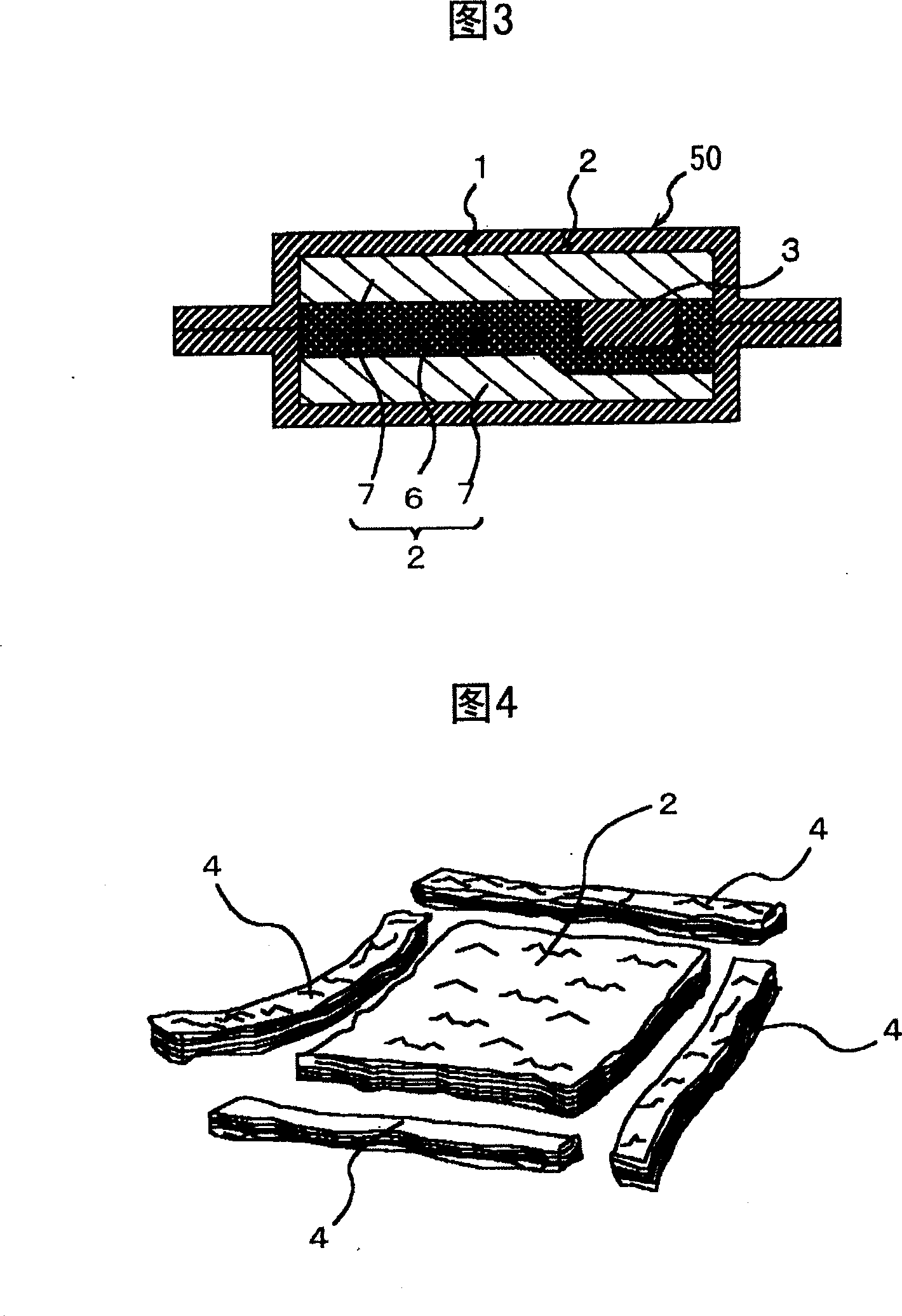

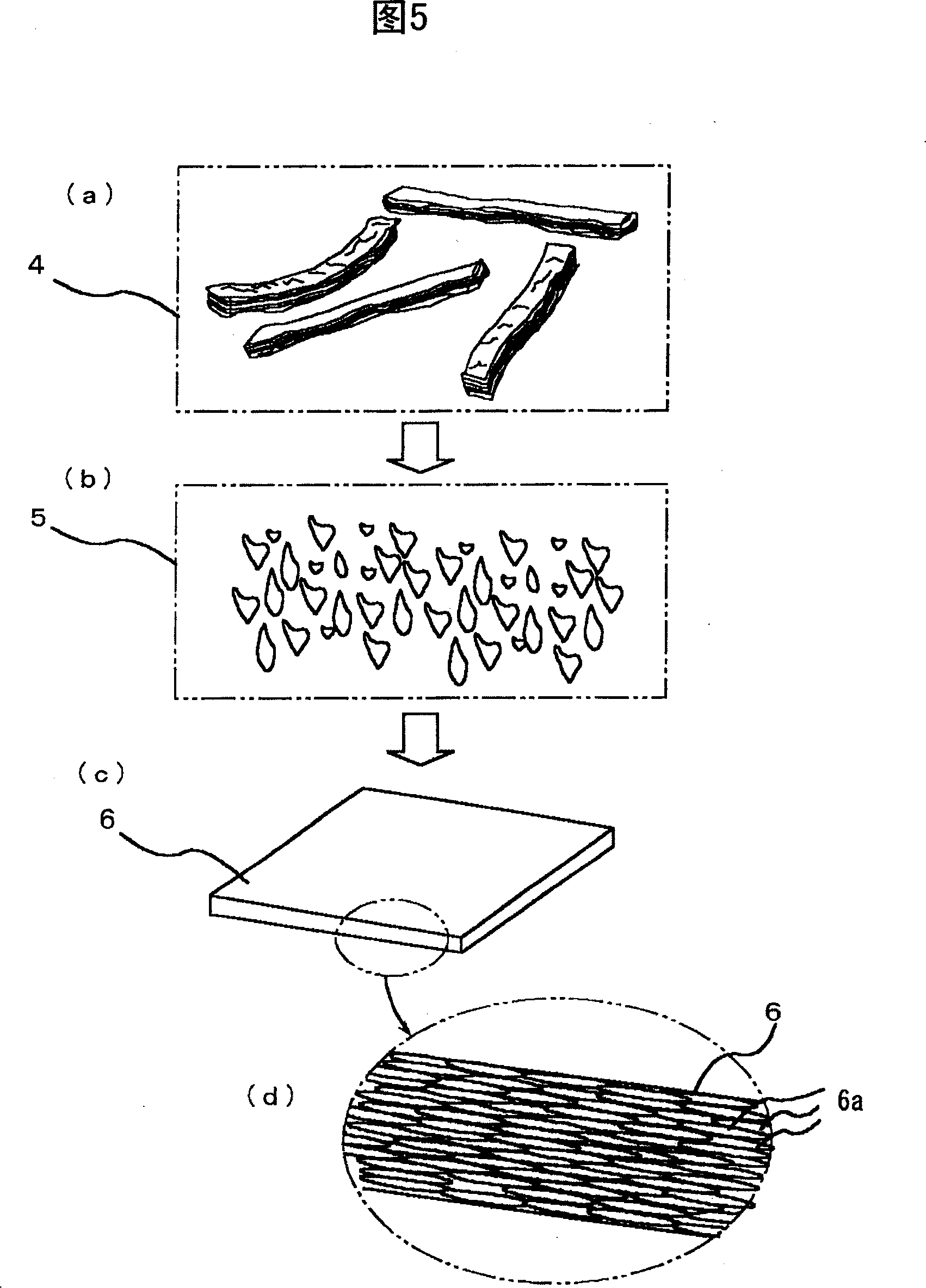

[0035] The overall structure of the refrigerator of this embodiment and its manufacturing method will be described with reference to FIG. 1 and FIG. 2 . Fig. 1 is a perspective view of a refrigerator according to a first embodiment of the present invention; Fig. 2 is a schematic diagram of a section of important parts in Fig. 1 .

[0036]The refrigerator of this embodiment is composed of two parts: an insulatin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com