Component belt conveyor wheel, component belt conveyor system and method for operating a component belt conveyor system

A technology of conveying system and component belt, applied in the direction of electrical components, electrical components, etc., can solve the problem of unable to pick up position correction, etc., and achieve the effect of high positioning accuracy and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

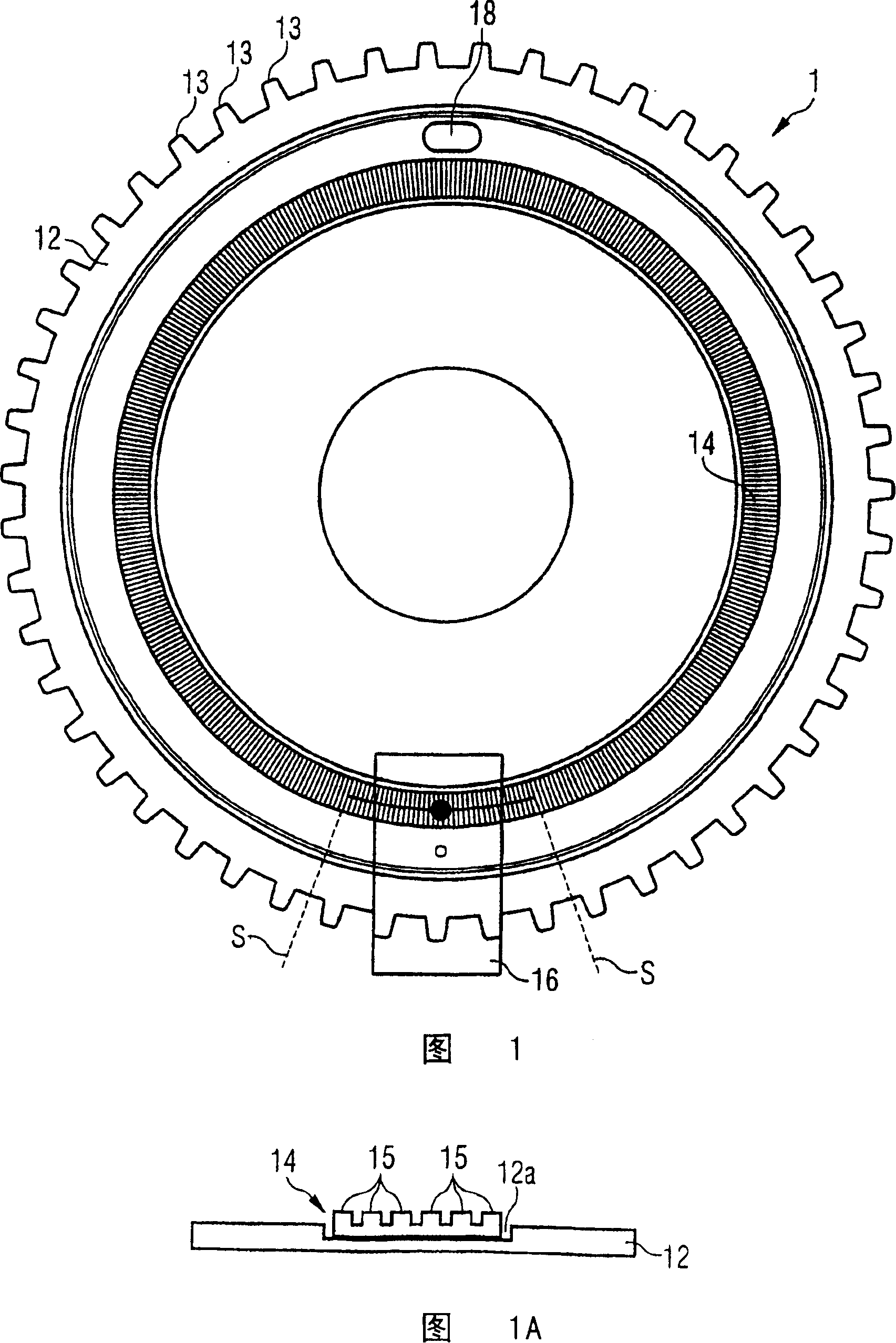

[0030] It can be seen from FIG. 1 that a schematic top view of a component belt conveyor wheel according to the invention is shown. The conveyor wheel 1 has an essentially disk-shaped body 12 provided with a plurality of conveyor pins 13 which are each arranged radially. The transport pins 13 are suitable to engage in their transport openings during the transport of the component strips in order to enable the transport of the component strips which is brought about by the rotation of the transport wheels.

[0031] An encoder wheel 14 is mounted on the disk-shaped body 12, for example in an annular groove. The encoder wheel 14 is firmly coupled to the disc-shaped object 12, so that a one-to-one correspondence between the conveying pins 13 and the encoder elements of the encoder wheel 14 is possible. If the component belt conveyor wheel 1 according to the invention passes by a sensor 16, which can detect the encoder element of the encoder wheel, then in cooperation with this se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com