Method for flow improvement and reduction of fouling in process equipment

A process equipment and fouling technology, applied in chemical instruments and methods, pollution prevention methods, heat transfer modification, etc., can solve the problem of reducing the scaling rate and achieve the effect of reducing the deposition rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will now be described in more detail with reference to preferred embodiments of the invention.

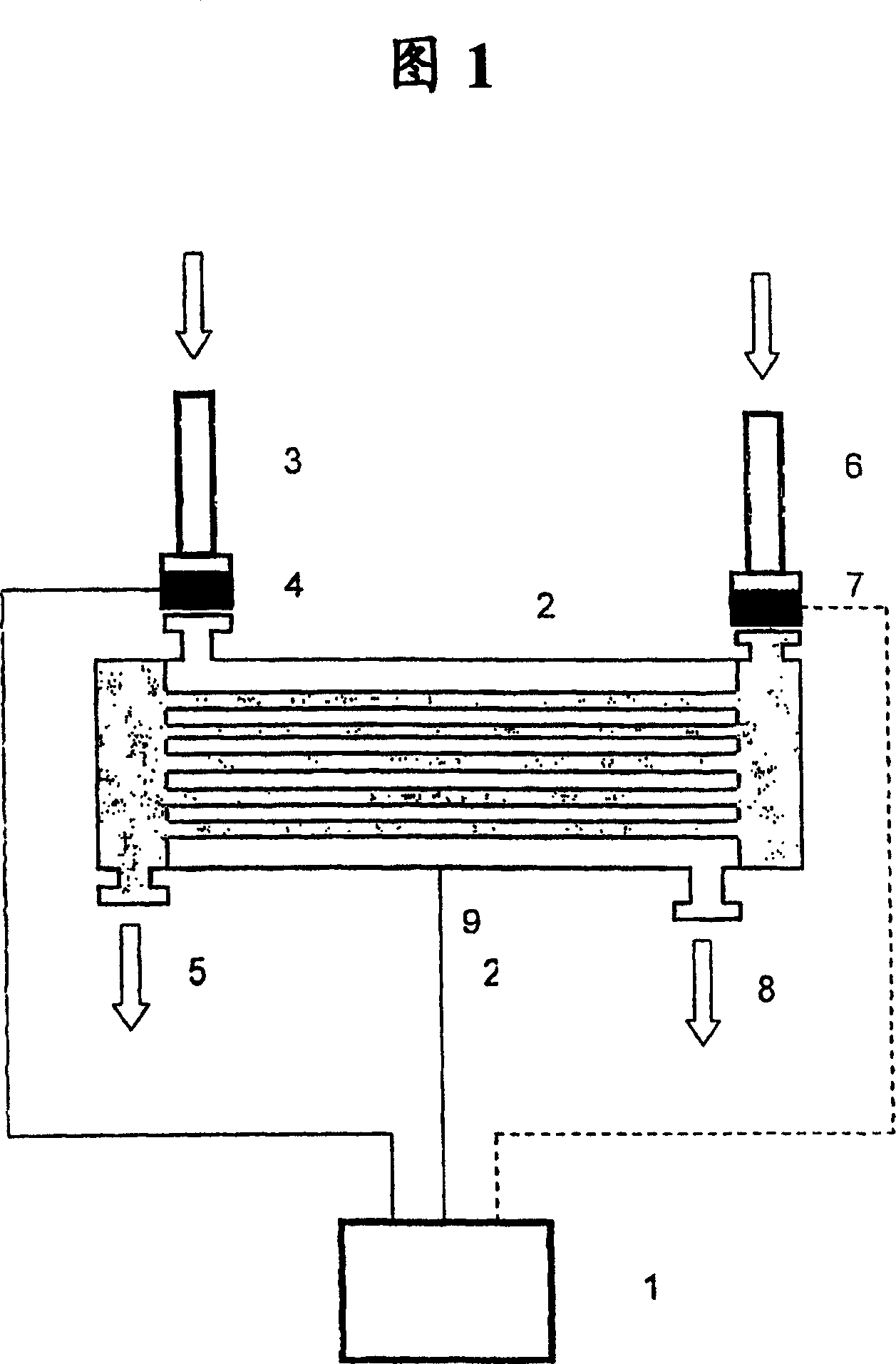

[0028] A preferred embodiment of the invention as implemented on a shell and tube heat exchanger is schematically shown in FIG. 1 . Arrows indicate flow direction. The invention 1 can be connected to the heat exchanger 2 by conventional two or more connectors (not shown in the figure). A connector is attached to the ring 4 in the inlet for the cooling / heating medium 3, which is electrically insulated from the rest of the system. A connector is connected to the ring 7 in the inlet for the process fluid 6, which is also electrically isolated from the rest of the system. The third connector is connected at point 9 on the heat exchanger itself. If the invention is used to improve the flow of a process fluid, the connection point 9 will be at the outlet of the process fluid 5 . In order to improve the flow of the cooling / heating medium, a connection poin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com