Production equipment for dewater and desolvent of lubricating oil additive and its technological method

A lubricating oil additive and desolventizing technology, which is applied in the fields of hydrocarbon oil dehydration/demulsification, petroleum industry, processing of hydrocarbon oil, etc. problems, to achieve significant technical effects and economic benefits, shorten the use time and the amount of heating steam used, and shorten the dehydration time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

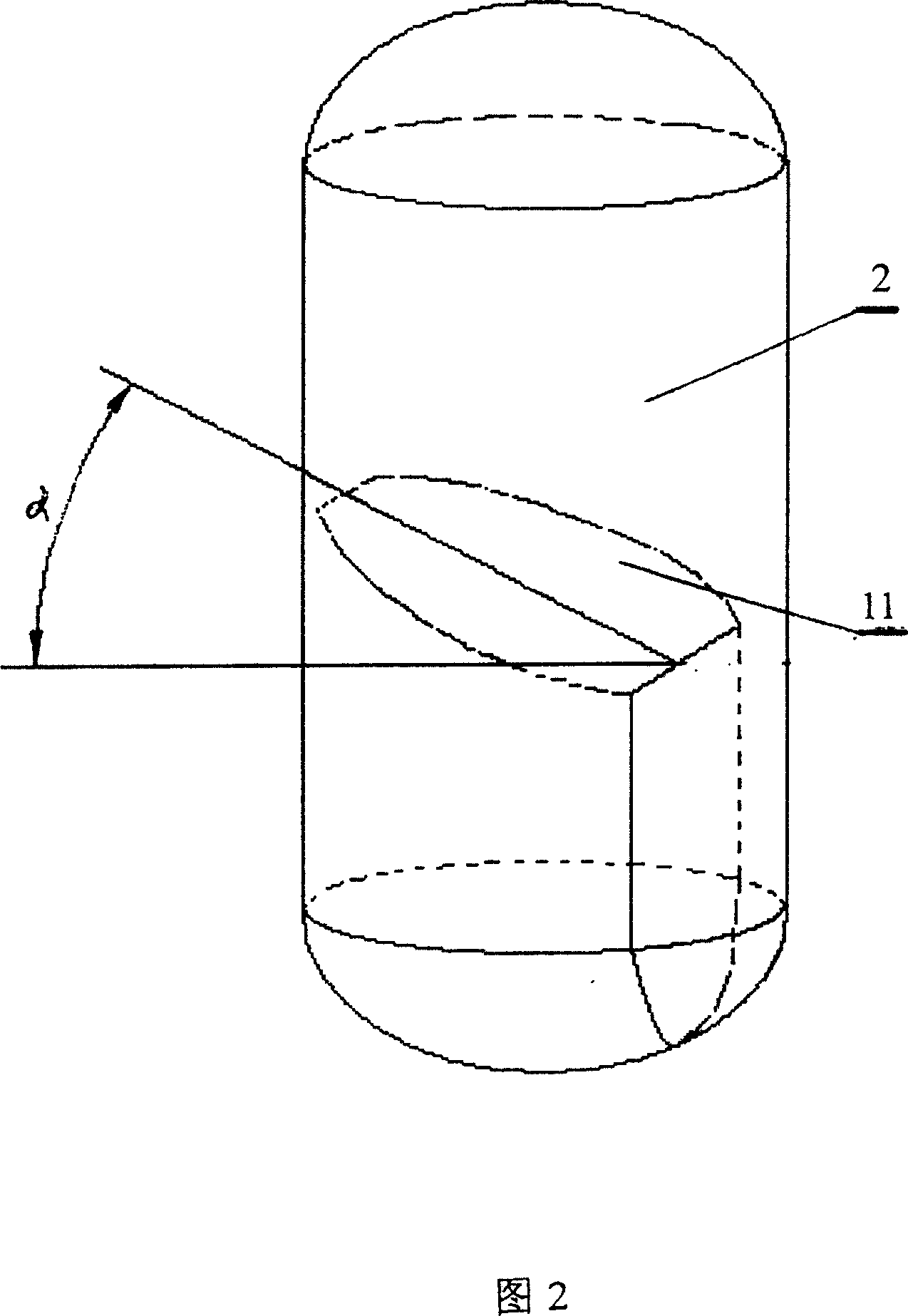

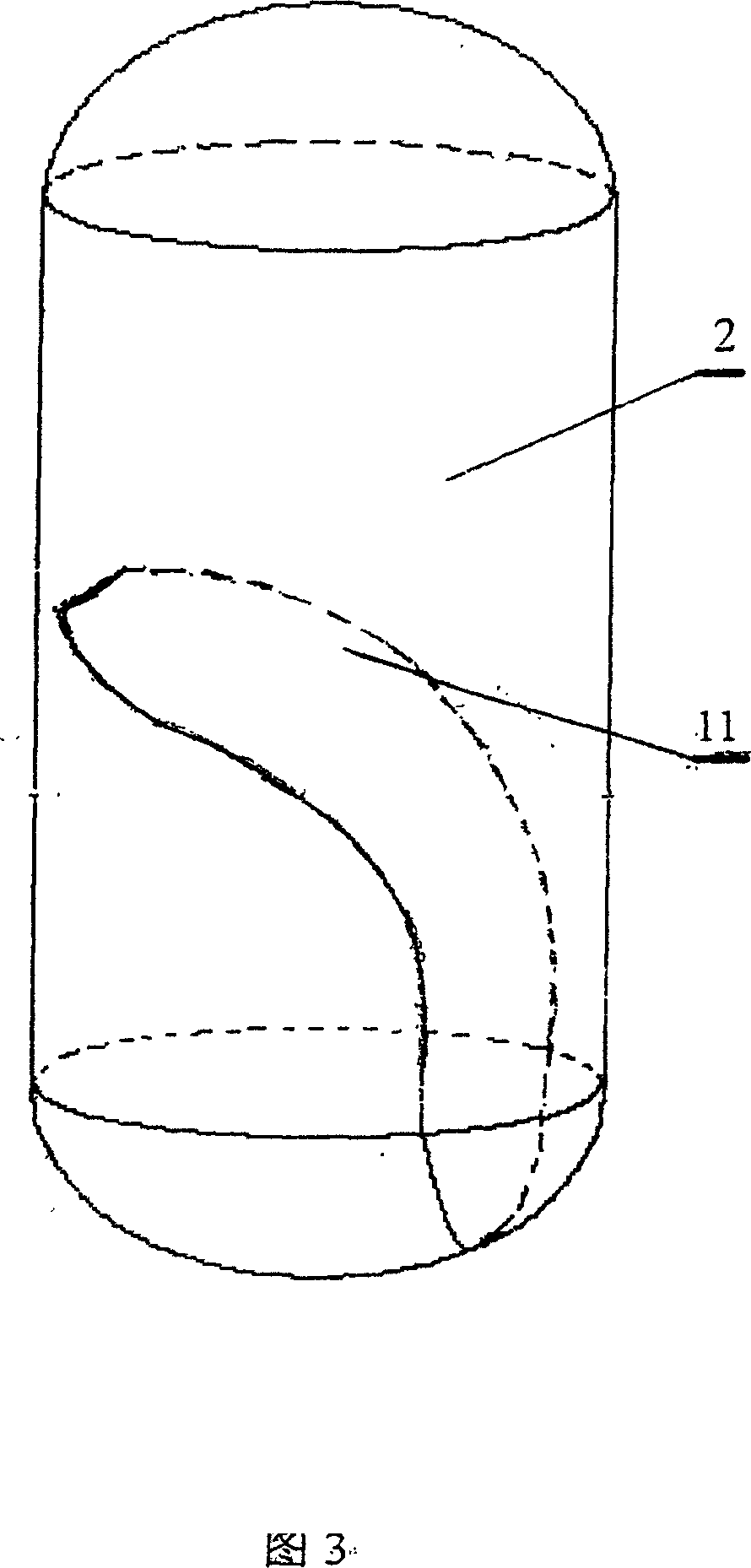

[0019] Equipment Embodiment 2: Equipment Embodiment 2 is basically the same as Embodiment 1. The difference is: the shapes of the flow-blocking baffles (11) in the receiving tank (2) are different. Refer to accompanying drawing 3. What the shape of the flow blocking baffle (11) adopted is arc shape.

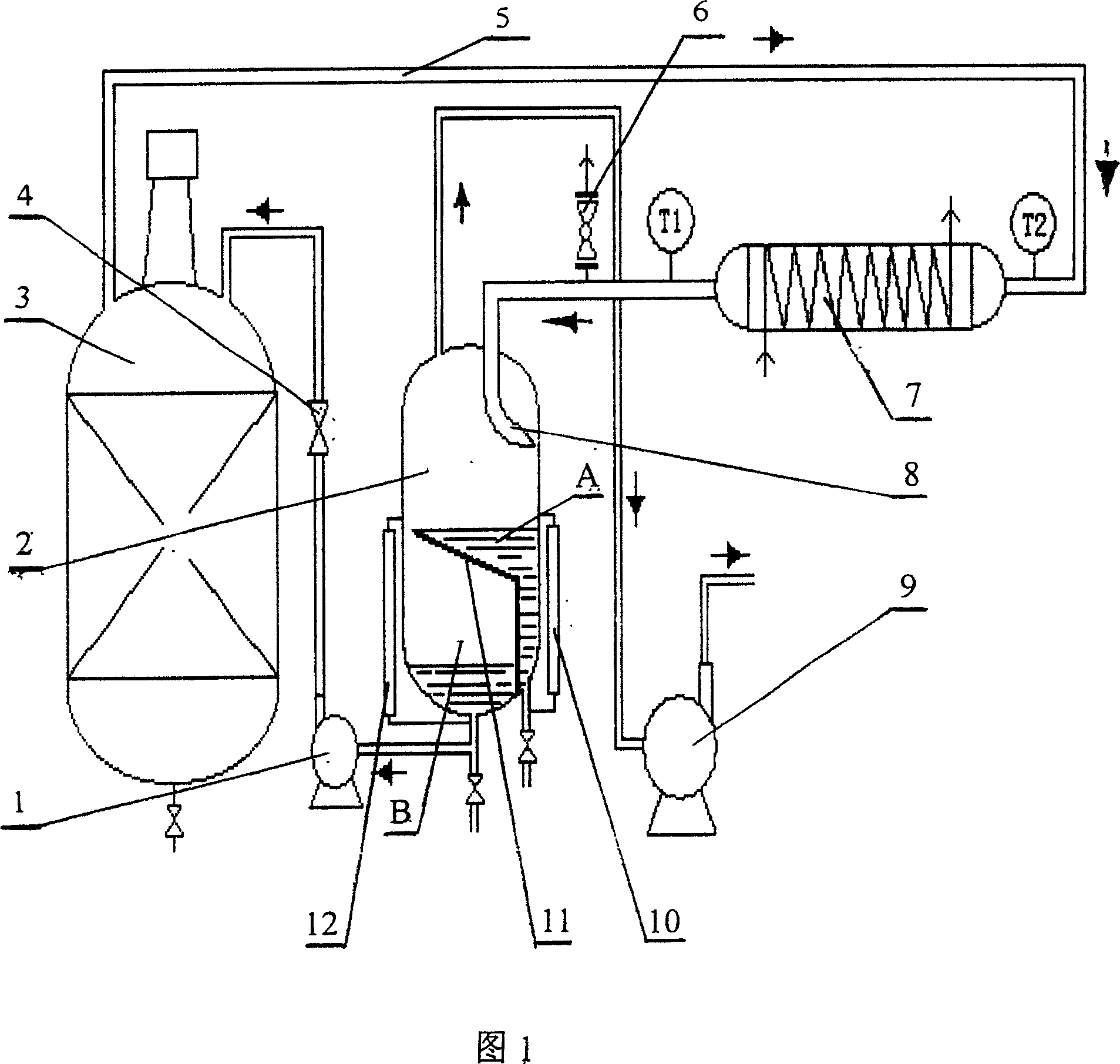

[0020]Lubricating oil additive dehydration, desolvent operation procedure embodiment: refer to accompanying drawing 1. In the production of lubricating oil additives, 500 kg of crude products are obtained through filtration. The crude product enters the dehydration and desolventization equipment of the present invention. First open the vent valve (6) to keep the whole dehydration and desolventization equipment system at normal pressure. Pass into the superheated steam of 160 ℃ to heat the additive crude product in the vacuum still (3) again. The gasoline solvent and water vapor contained in the crude product are precipitated and transported to the condenser (7) through the pi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com