Multiturn arranged cocoon brushing set

A technology of mechanical arms and bridge gears, applied in the direction of silk reeling, etc., can solve the problem that the automatic silk reeling machine cannot meet the needs of the cable thread supply cocoon, so as to meet the cable thread supply demand, improve the required capacity, increase the effect of width

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

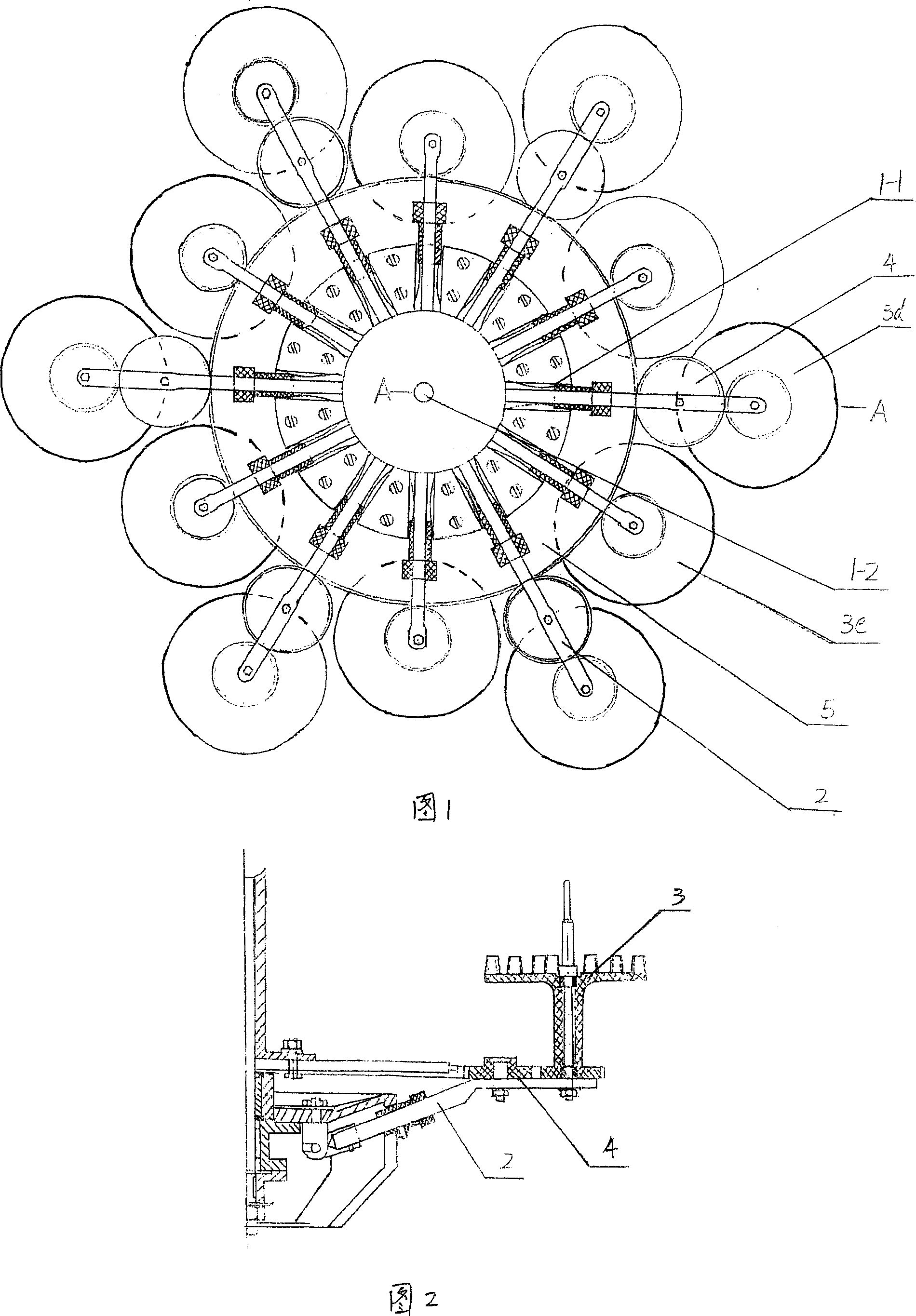

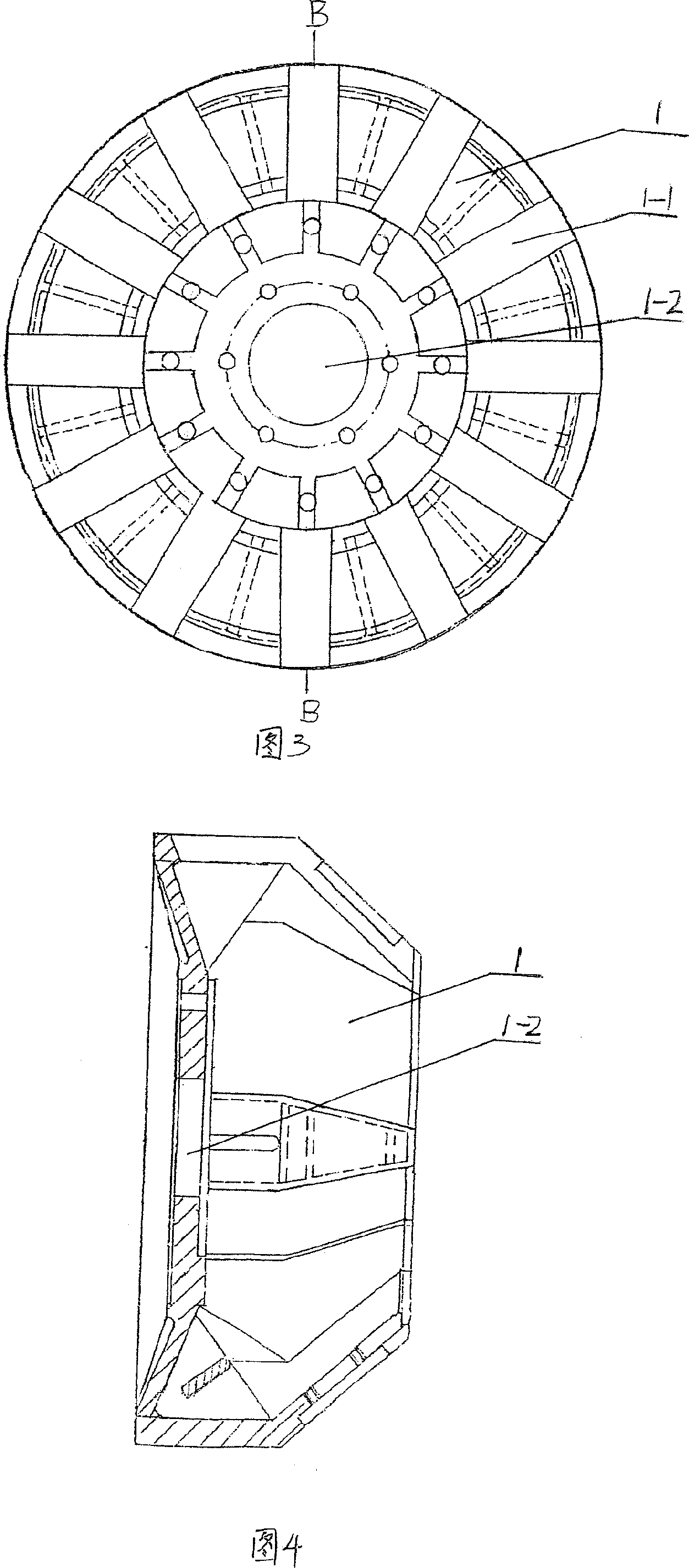

[0017] Embodiment 1: the multi-circle arrangement threading device of this example, as Fig. 3, Fig. 4, has a groove frame 1 that has groove 1-1, and groove frame center is provided with axle hole 1-2, and its size and thread thread suitable for the diameter of the shaft. There are 12 grooves 1-1, which are evenly distributed on the groove frame around the axis hole. As shown in Fig. 1 and Fig. 2, a mechanical arm 2 is arranged in the groove 1-1, and one end of the mechanical arm is connected to the shaft hole of the groove frame by a bolt, and the other end is connected with a cable thread body 3. Among them, the odd-numbered mechanical arms 2 are connected with the cable body 3e by bolts, and the six cable bodies 3e are all meshed with the large gear 5, and form the first circle arrangement; the even-numbered mechanical arms are connected with the bridge gear 4 by bolts, and the bridge One side of the gear meshes with the large gear 5, and the other side meshes with the cabl...

Embodiment 2

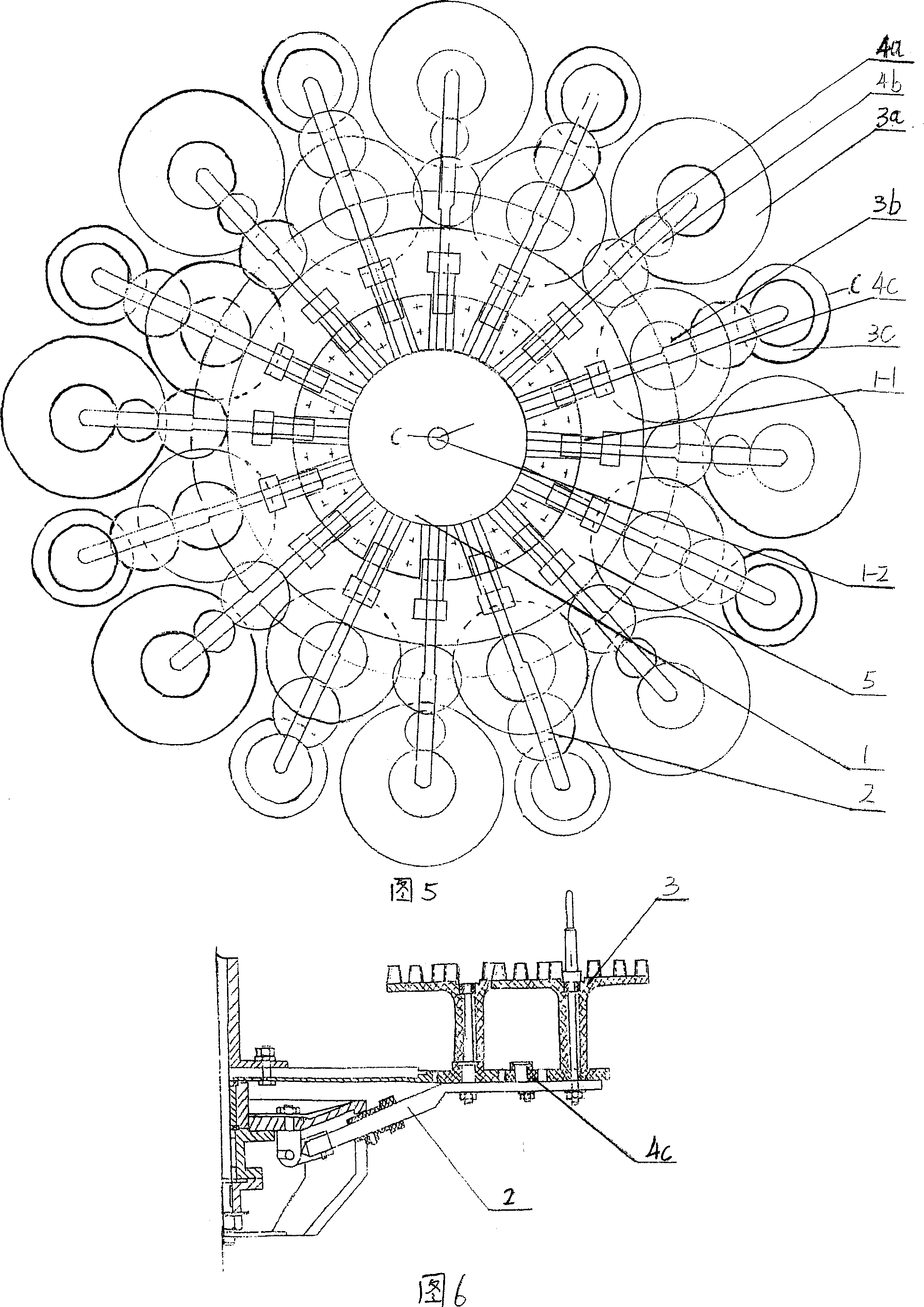

[0019] Embodiment 2: As shown in Figure 5 and Figure 6, there are 16 grooves 1-1, which are evenly distributed on the groove frame around the axis hole. Wherein, on the odd-numbered mechanical arms 2, the first bridge gear 4a and the second bridge gear 4b that are matched are connected by bolts, the first bridge gear 4a meshes with the large gear 5, and the second bridge gear 4b meshes with the second bridge gear 4b. A cable thread body 3a, the diameter of the first cable thread body 3a is greater than the diameter of the first bridge gear 4a and the second bridge gear 4b; the even-numbered mechanical arm 2 is connected with a third bridge gear 4c by bolts, and its two sides Coordinated with the second cable body 3b and the third cable body 3c, one side of the second cable body 3b meshes with the large gear 5, the other side meshes with the third bridge gear 4c, and the other side of the third bridge gear 4c meshes with the large gear 5. The side is engaged with the third cord...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com