Method for manufacturing color separation film

A manufacturing method and a technology for a color separation film, which are applied in optical elements, optics, instruments, etc., can solve the problems of limiting the quality of the filter material 24, the photoresist 116 cannot withstand high temperature, and the characteristics of the extinction ratio are not ideal.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

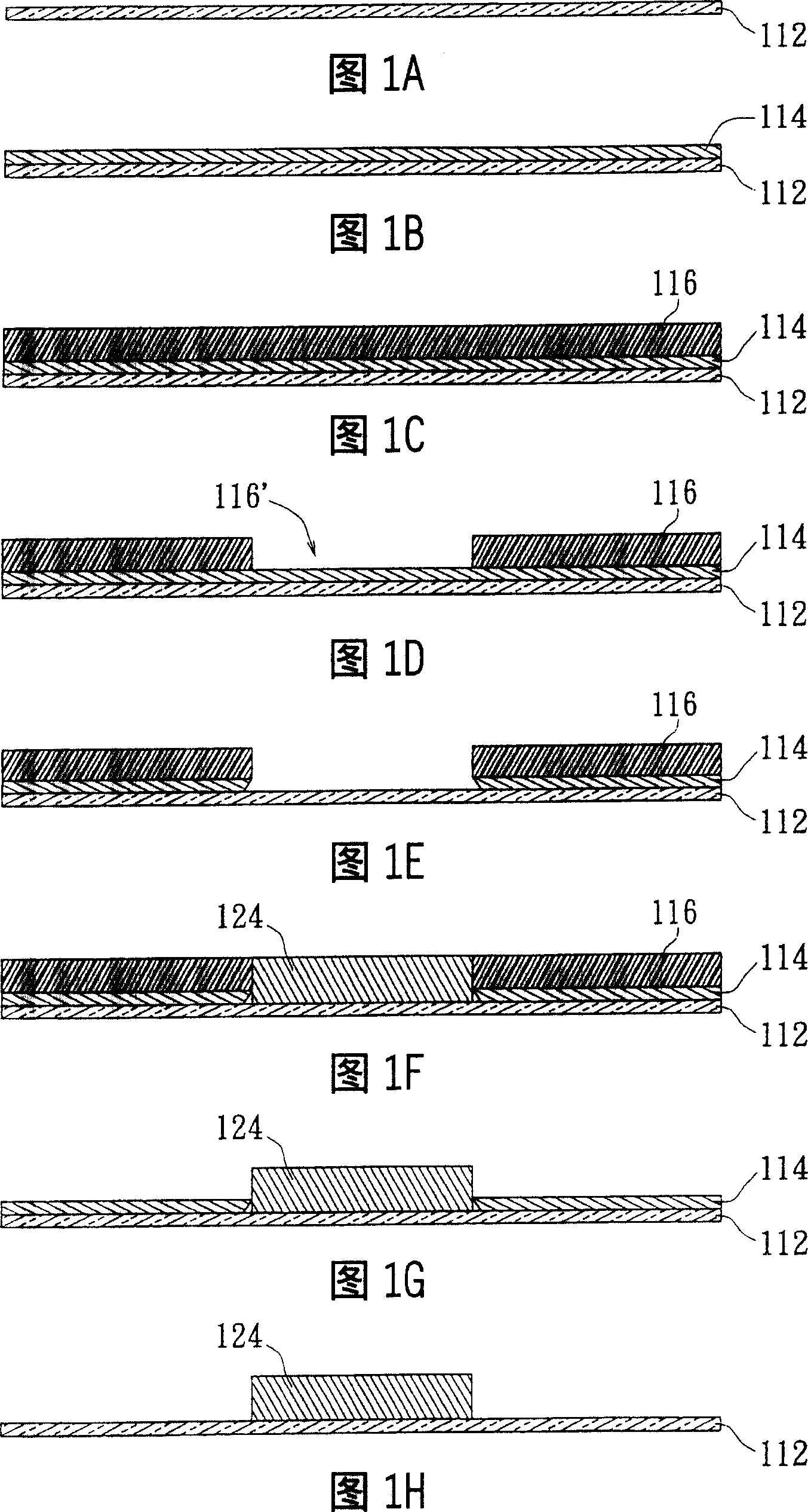

[0019] In order to make the object and features of the present invention more comprehensible, preferred specific examples of the present invention are described with reference to the accompanying drawings.

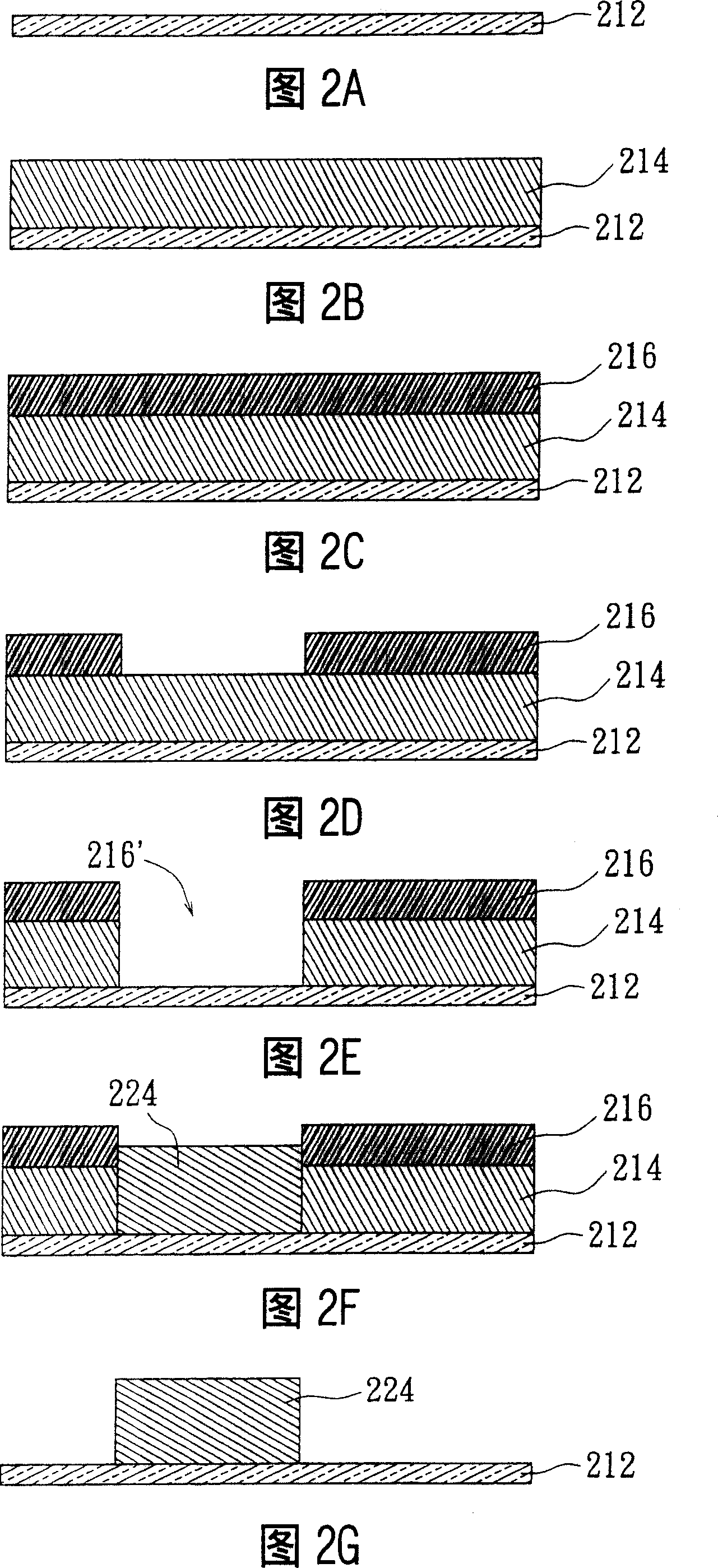

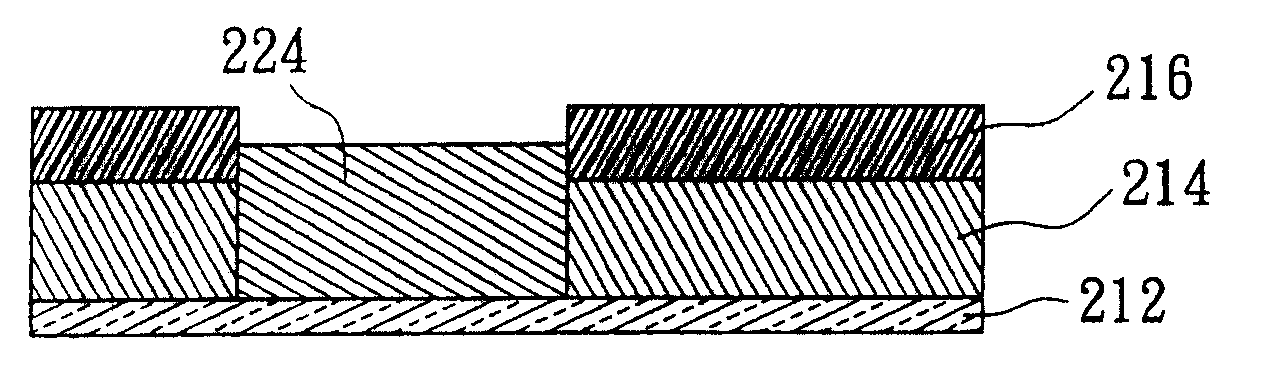

[0020] Referring to Fig. 2A to Fig. 2G, it is the flow process of the present invention, comprises the following steps:

[0021] S200, as shown in FIG. 2A, first prepare a base material 212;

[0022] S202, as shown in FIG. 2B , forming a metal layer 214 on the substrate 212 by vapor deposition;

[0023] S204, as shown in FIG. 2C , applying a photoresist 216 on the metal layer 214 by spin coating;

[0024] S206 is soft roasted;

[0025] S208 using lithography and a photomask with a predetermined pattern to expose certain predetermined portions of the photoresist 216;

[0026] Baking after S210 exposure;

[0027] S212, as shown in FIG. 2D, develop and remove part of the photoresist 216 to define a gap 216';

[0028] S214 is soft-baked at a low temperature at room temper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com