Method and device for preparing metal-based composite material by electric current direct heating dynamic sinter hot pressing

A technology for composite material and preparation device, which is applied in the field of current direct heating dynamic sintering and hot pressing preparation of metal matrix composite materials, can solve problems such as technical and theoretical problems yet to be studied, and achieves shortening powder sintering time, improving production efficiency and saving energy. energy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

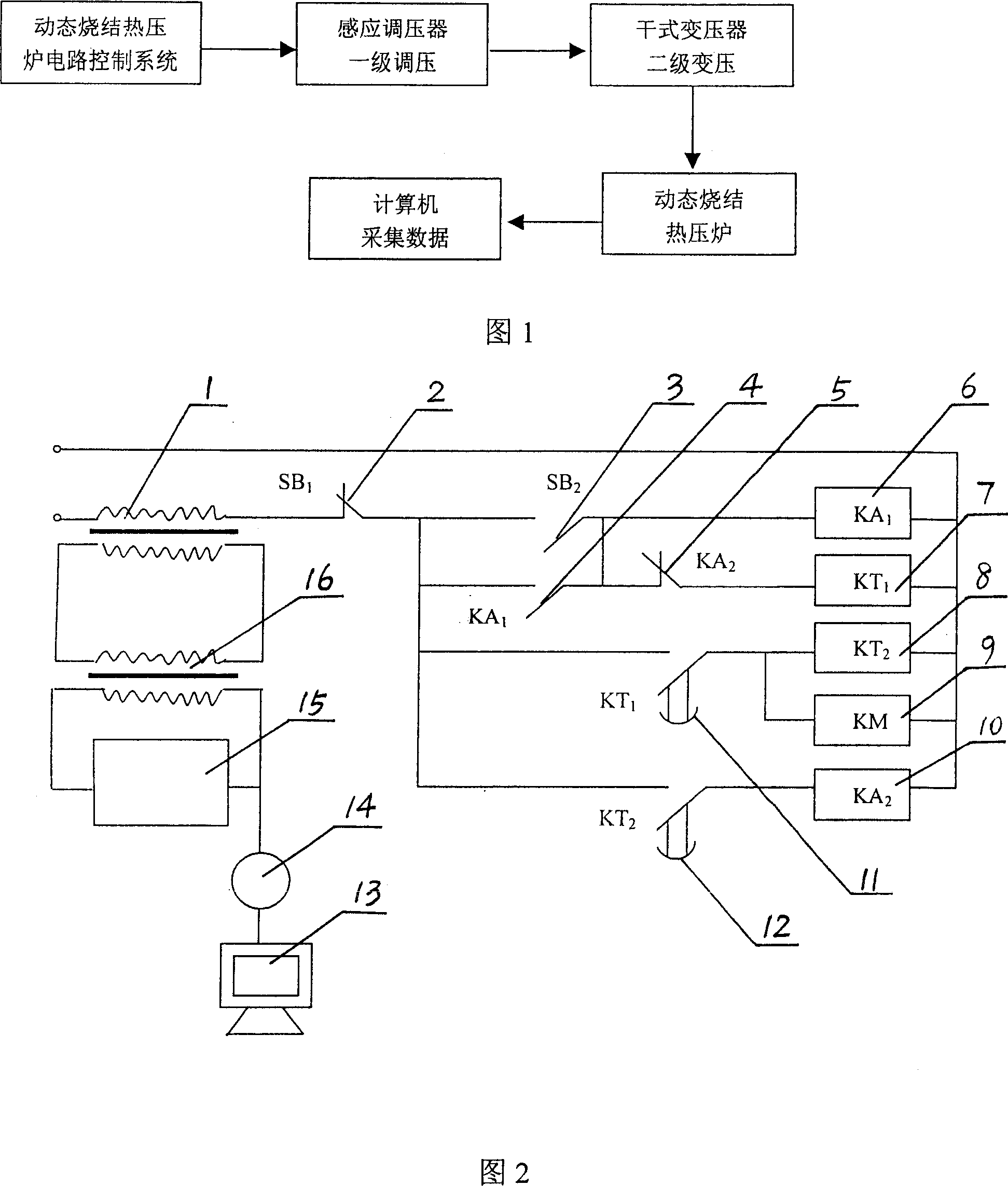

[0049] The present invention adopts a current direct heating dynamic sintering hot pressing furnace. As shown in Figure 1, the current direct heating dynamic sintering hot pressing furnace consists of five parts. The order of connection is: circuit control system, induction voltage regulator, dry transformer, Hot pressing furnace and computer data acquisition system.

[0050] As shown in FIG. 2, the output terminal of the circuit control system is connected with the input terminal of the induction voltage regulator 1, and the circuit control system provides a periodically changing working current, which is output to the induction voltage regulator 1. The function of the induction voltage regulator 1 is to complete the first voltage regulation, and the input voltage can be changed by controlling the induction voltage regulator 1. It can adjust the voltage from 220V to 100~500V. The input end of the dry-type transformer 16 is connected to the output end of the induction voltage regu...

Embodiment 2

[0054] The preparation of iron-based composite material reinforced with 10% SiC particles by volume percentage (additional 0.5-1% zinc stearate by mass fraction) is formed by pressing by the general powder metallurgy sintering method, in a protective atmosphere for decomposing ammonia Sintering, the sintering temperature is 1110~1150℃, and the holding time is 1~1.5 hours. Its performance is shown in Table 2:

[0055] Table 2 Mechanical properties of ordinary powder metallurgy sintered materials

[0056] SiC volume

[0057] Using the current direct heating dynamic sintering hot pressing process of the present invention, the mechanical properties of the iron-based composite material containing 10% SiC by volume percentage prepared by direct heating and sintering under the output voltage of the induction transformer at 360V for different time (interval 100s) are shown in Table 3:

[0058] Table 3 Mechanical properties of sintered materials under direct current heating

[00...

Embodiment 3

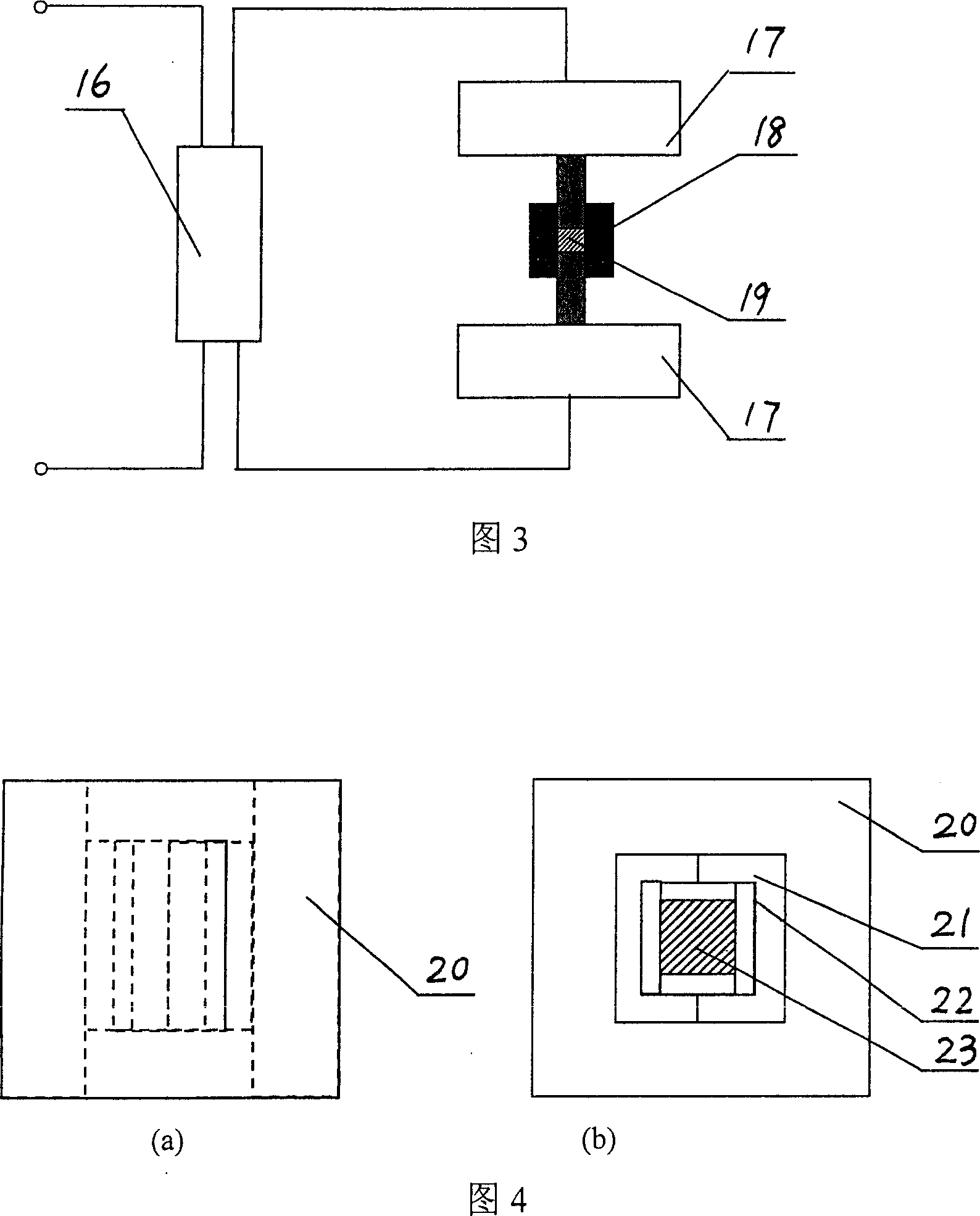

[0062] For the current direct heating sintering process, if the mold is not processed, the current will pass through the mold and the sintered material at the same time. The comparison process can be defined as an ordinary current dynamic hot pressing sintering process; while the current direct heating dynamic sintering hot pressing process of the present invention Through the processing of the mold, the current completely passes through the sintered material. The mechanical properties of 10% SiC iron-based composites sintered by these two processes are shown in Table 4:

[0063] Table 4 Preparation of 10% SiC by different processes p Density and mechanical properties of / Fe composite

[0064]

[0065] It can be seen that the density and mechanical properties of the samples prepared by the electric current direct heating dynamic sintering process are higher than those of the ordinary electric current heating hot pressing sintering process. Therefore, the improvement of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| current | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com