Wet type dust collection unit

A dust collection device, wet technology, applied in the direction of combination device, disperse particle filtration, use of liquid separation agent, etc., can solve the problem of increasing the load of the septic tank, and achieve the effect of reducing the load of the septic tank and reducing the load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

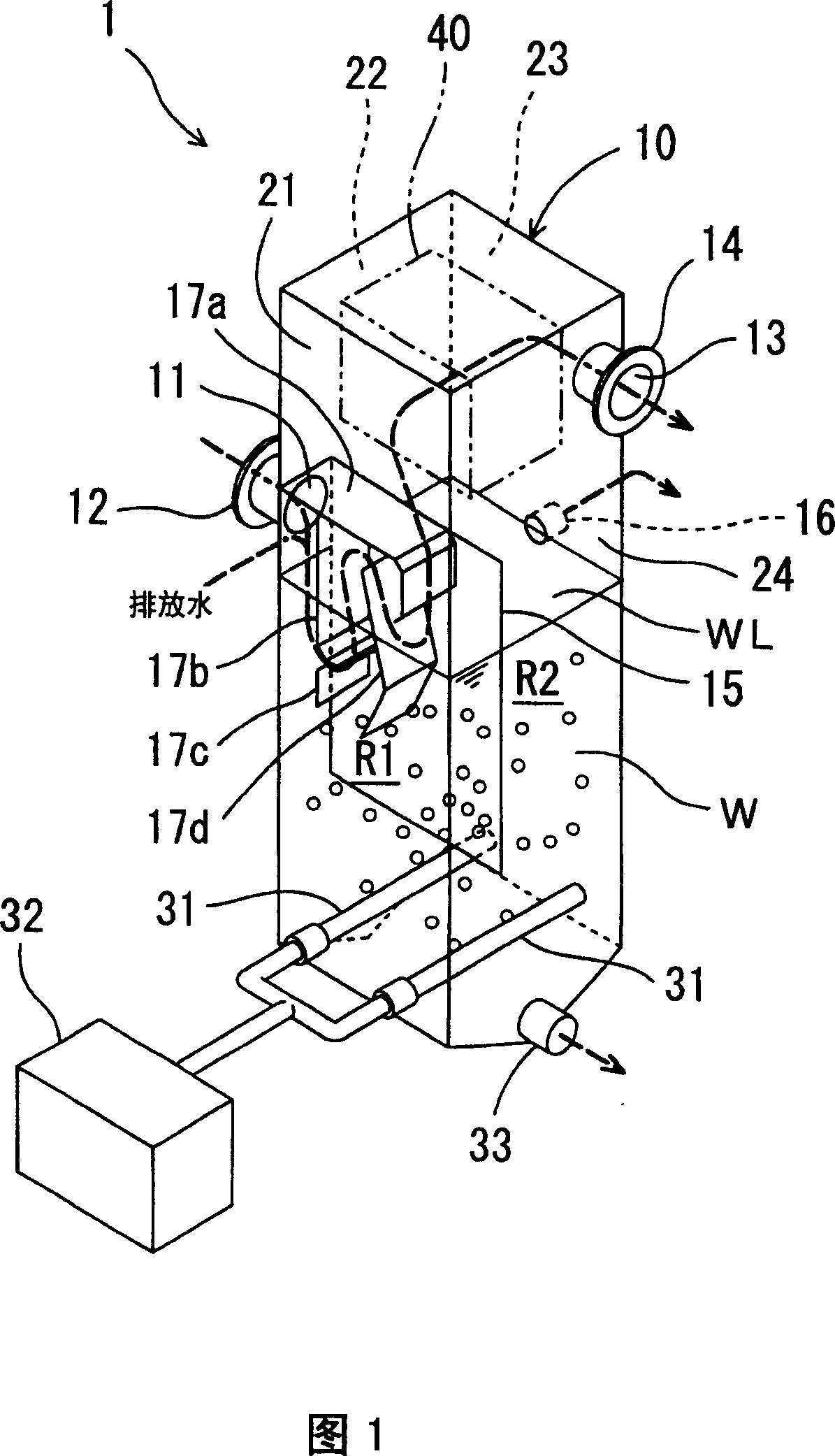

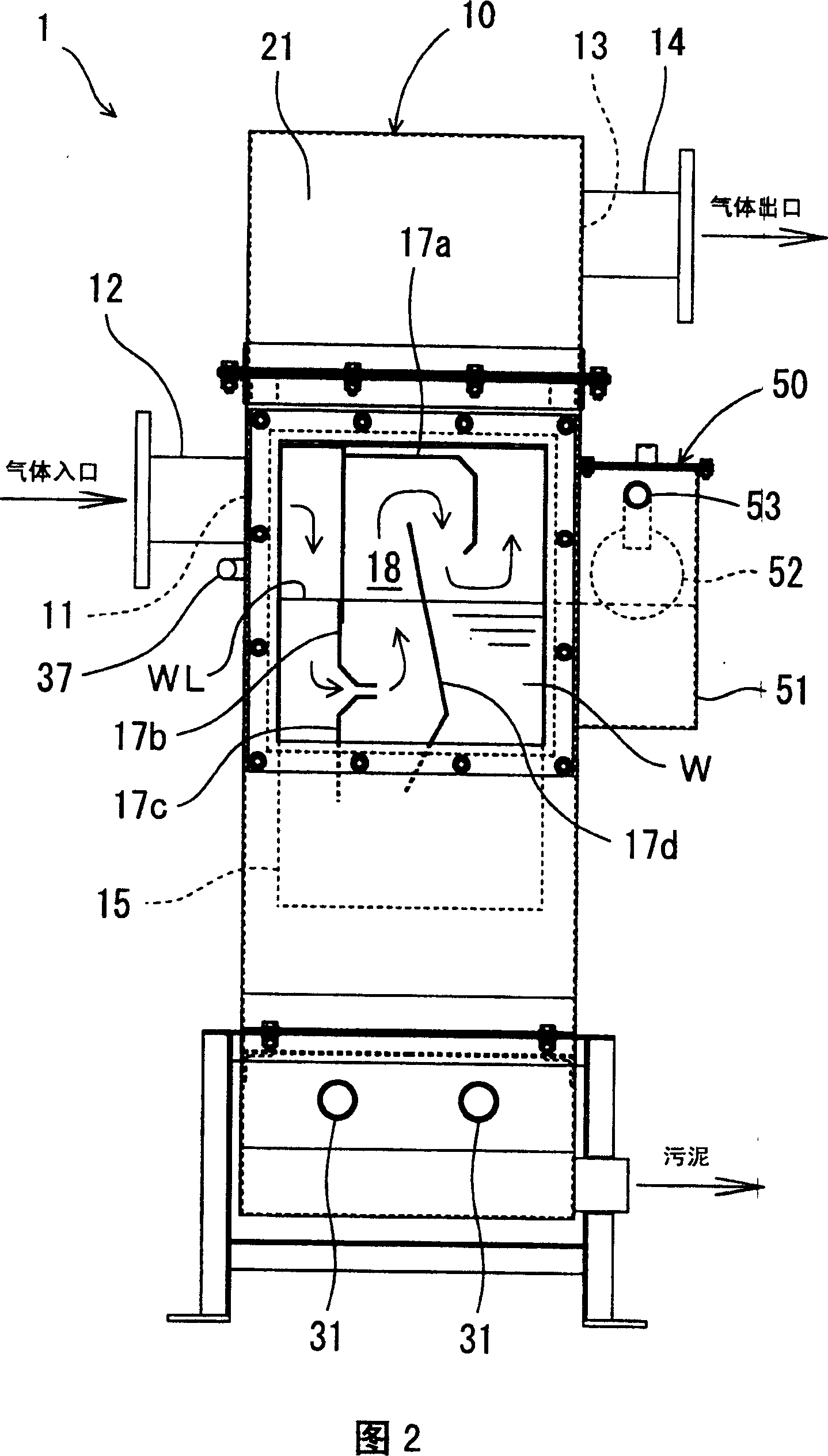

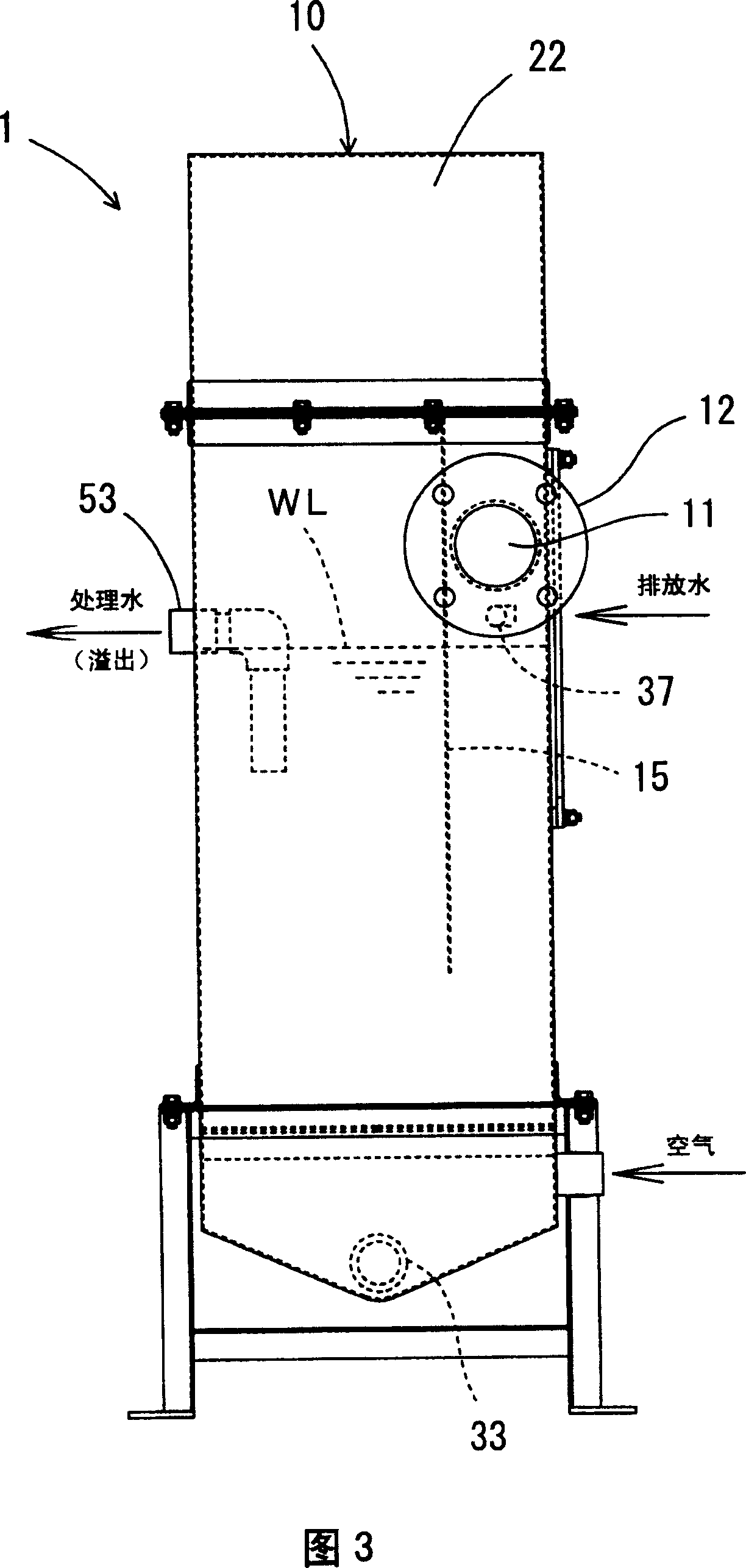

[0032] As shown in FIGS. 1 to 4 , the wet dust collector 1 includes a vertically long substantially rectangular parallelepiped airtight casing 10 . On the left side 22 of the casing 10, an air inlet 11 for introducing gas is formed. The air intake port 11 is located on the upper side slightly higher than the vertically central portion of the left side surface 22 and is formed on the front end side. A suction pipe 12 is provided around the suction port 11 . On the right side 24 of the casing 10, an exhaust port 13 for leading out gas is formed. The exhaust port 13 is formed on the upper end side and the rear end side of the right side surface 24 . An exhaust pipe 14 is provided around the exhaust port 13 .

[0033] Treated water W is stored inside the housing 10 . To the rear side 23 of the casing 10, an overflow pipe 16 for discharging the treated water W whose water volume has been increased is connected. Therefore, the height of the liquid level WL of the treated water ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com