Concrete convenient spelled waler system and its construction process

A concrete and convenient technology, applied in the direction of formwork/formwork/work frame, connection parts of formwork/formwork/work frame, building components, etc., can solve the problem of large loss of formwork, large supports and fasteners, and cannot be repeated Use and other issues to achieve the effect of small template loss, uniform force, and guaranteed quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

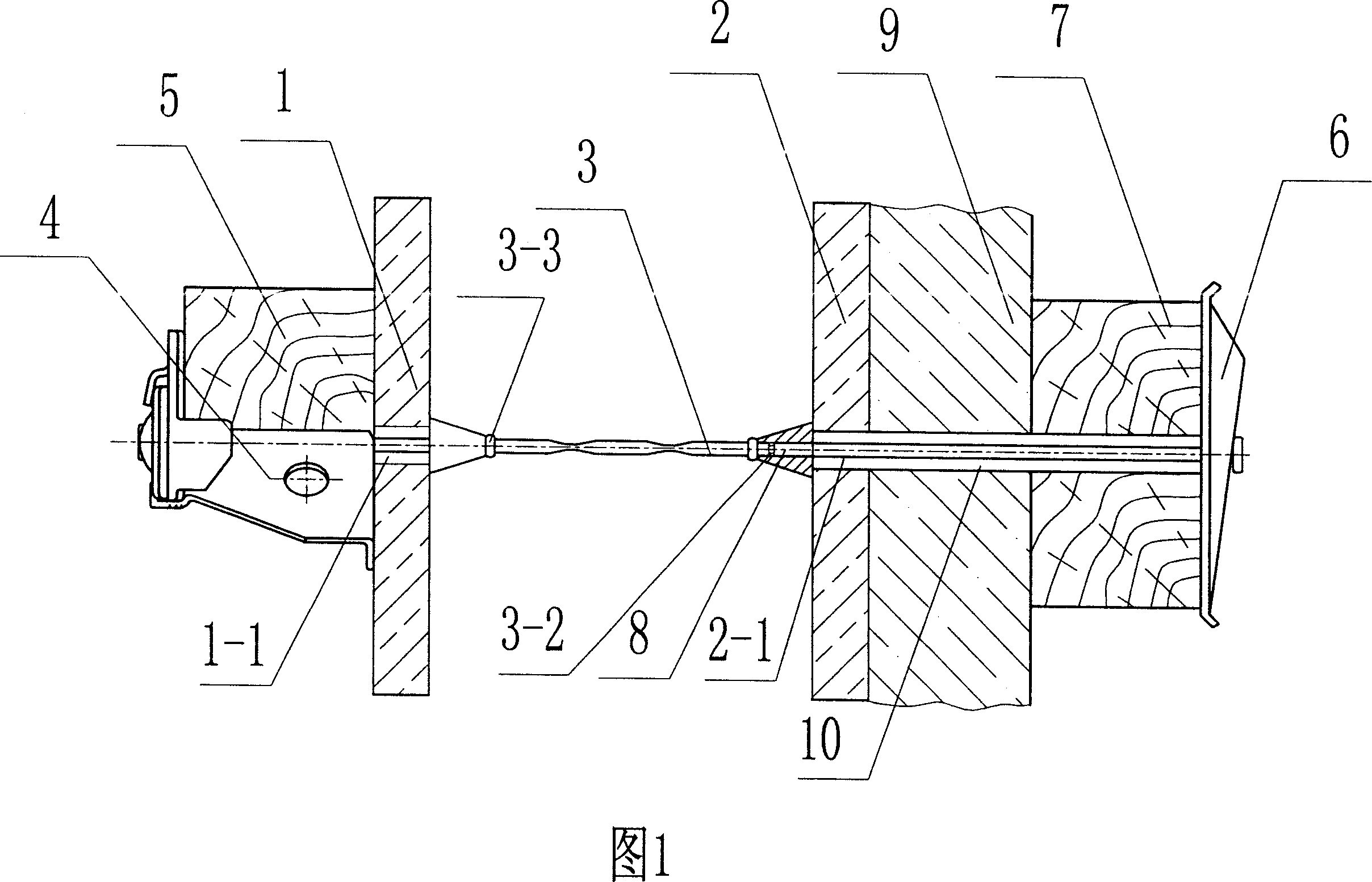

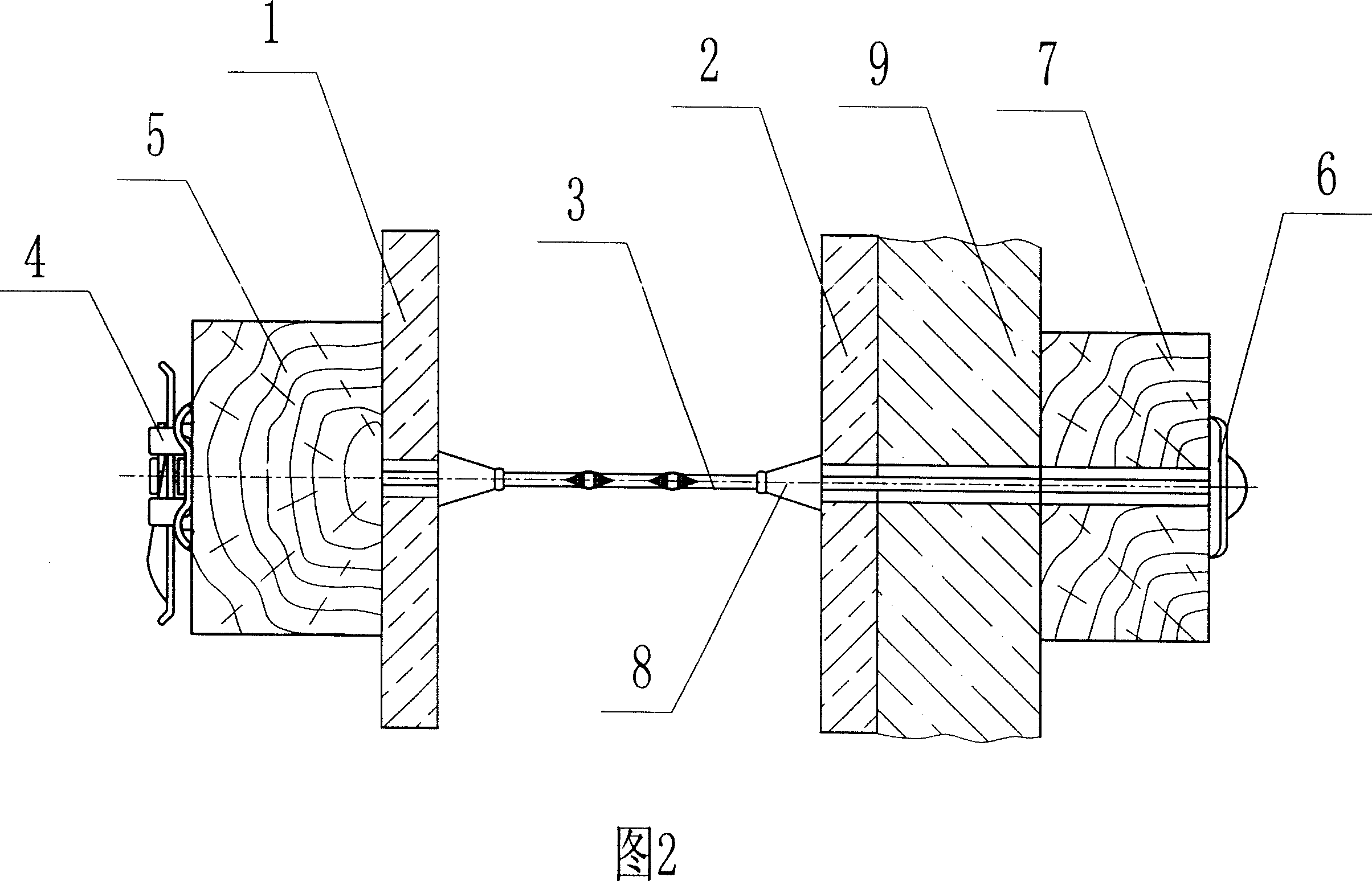

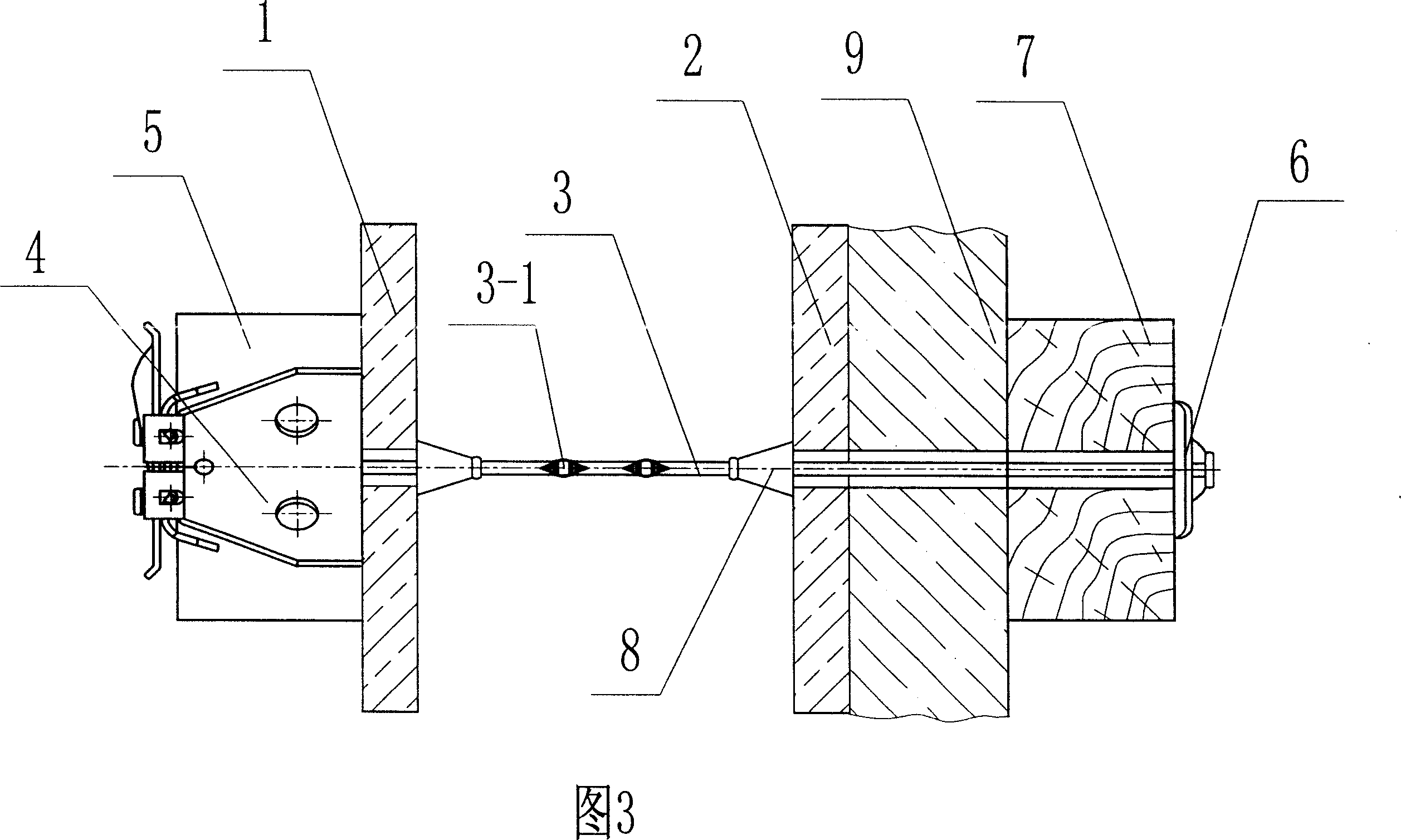

[0029] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

[0030] As shown in the figure, this convenient concrete formwork cross brace structure mainly includes a left formwork 1 and a right formwork 2, which are erected and fixedly connected to the starting wooden square at the bottom. There is a group of left template prefabricated holes 1-1 on the left template 1, and a group of right template prefabricated holes 2-1 are opened on the right template 2, and the left template prefabricated holes 1-1 and the right template prefabricated holes 2-1 are connected to each other. One-to-one correspondence; steel bars 3 run through each left formwork prefabricated hole 1-1 and right formwork prefabricated hole 2-1, and one end of the steel bar 3 is connected with a three-in-one clamping piece 4, through the three-in-one clamping piece 4 the first wooden The square 5 is tightly pressed and fixed between the three-in-one cl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com