Laminated seamless belt, its manufacturing method and imaging device containing the same

An imaging device, a seamless technology, applied in the direction of equipment, lamination, lamination device, etc. of the electrical recording process using charge patterns, which can solve the problems of low durability, poor creep performance, and unfavorable manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

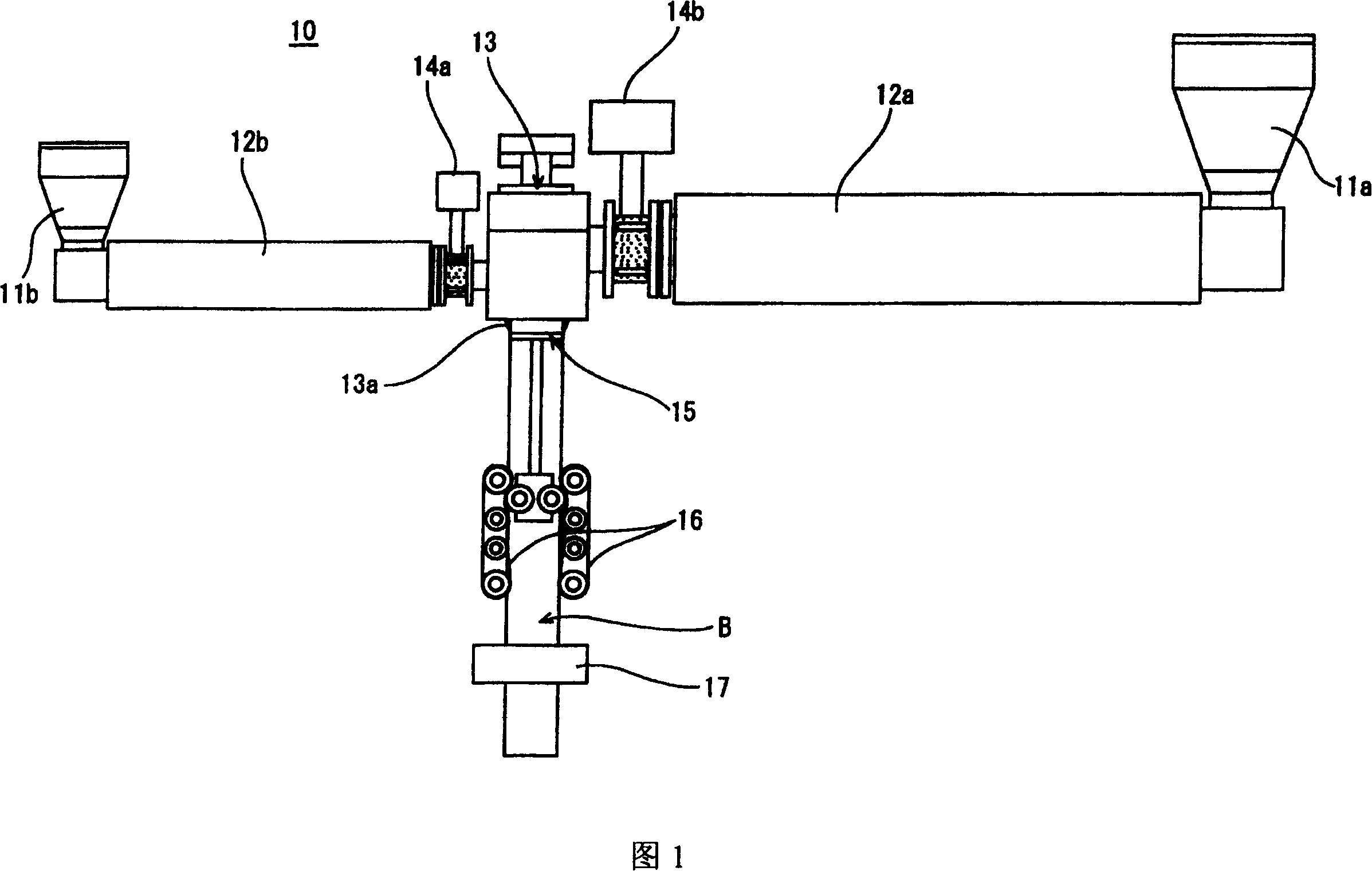

[0114] The conductive masterbatch A and the polyester thermoplastic elastomer were dry-blended, wherein the conductive masterbatch A was added in an amount of 0.5 parts by weight for every 100 parts by weight of the polyester thermoplastic elastomer. The mixture was kneaded at 210° C. using a twin-screw extruder. Granules of base material are thus obtained. The pellets were supplied to the hopper 11a of the lamination extruder as shown in FIG. 1 .

[0115] Pellets made of polyester thermoplastic elastomer are supplied to the hopper 11a. Start the single-screw extruder for the respective pellets. The number of revolutions of the gear pump 14a on the base material side was adjusted to 12.1 rpm, and the number of revolutions of the gear pump 14b on the outer layer material side was adjusted to 1.4 rpm. The molten resin is supplied to the right-angle die 13 .

[0116] The outer layer material and the base layer material were laminated to each other in a square die 13 set at a ...

Embodiment 2

[0118]The polyester thermoplastic elastomer, the conductive masterbatch A and the flame retardant masterbatch are dry mixed to form a base material, wherein the amount of the conductive agent is 0.5 parts by weight relative to the amount of the polymer component, and the amount of the flame retardant additive is relative to the entire tape The weight of is 25 parts by weight. These components were kneaded under the same conditions as in Example 1 using a twin-screw extruder. A laminated seamless belt of Example 2 was produced in the same manner as in Example 1 by using pellets composed of the base material obtained in this way. The belt has high formability.

Embodiment 3

[0120] The conductive masterbatch A of Example 2 was replaced with conductive masterbatch B to form the base material. The components were kneaded in the same manner as in Example 2. The content of the ion conductive agent was 0.7 parts by weight per 100 parts by weight of the polyester thermoplastic elastomer. The content of melamine was 25 parts by weight relative to the weight of the entire belt. A laminated seamless belt of Example 3 was produced in the same manner as in Example 1 by using pellets composed of the base material obtained in this way. The belt has high formability.

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com