Paste, resistor paste, methods for producing them, and variable resistor

A paste and resistor technology, applied in the manufacture of resistors, adjustable resistors, resistors, etc., can solve the problems of substrate materials such as ammonia resistance, poor storage stability, and environmental impact, and achieve good adhesion , good storage stability, resistance value change and the effect of low noise of sliding resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Hereinafter, embodiments of pastes, resistor pastes, their manufacturing methods, and varistors related to the present invention will be described with reference to the drawings.

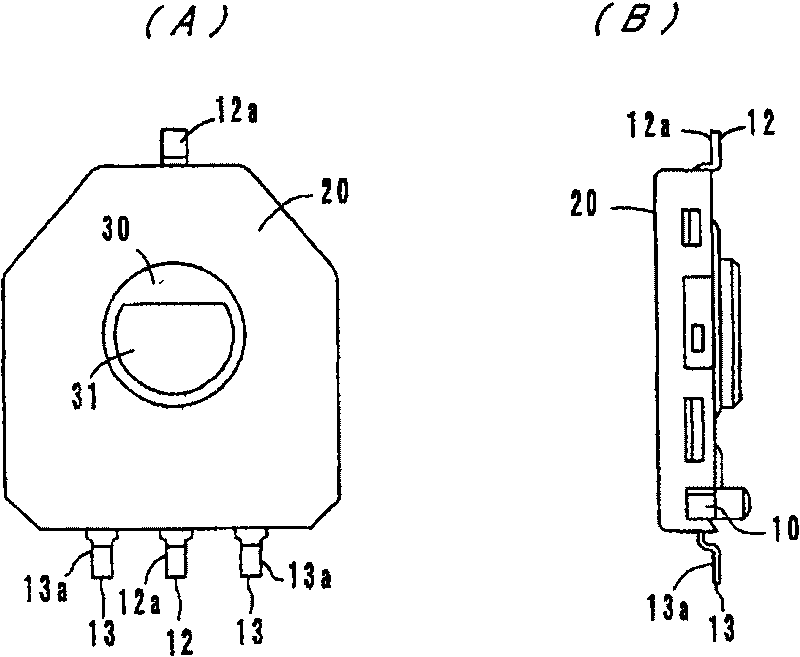

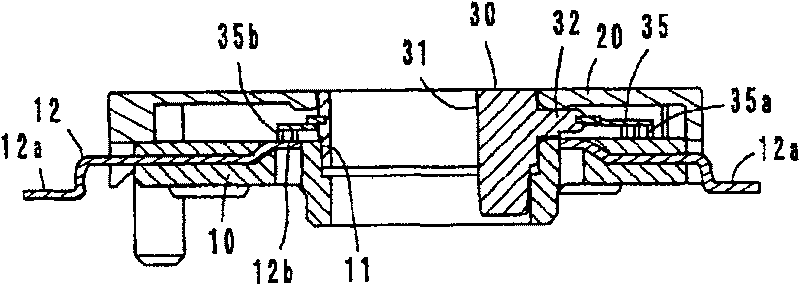

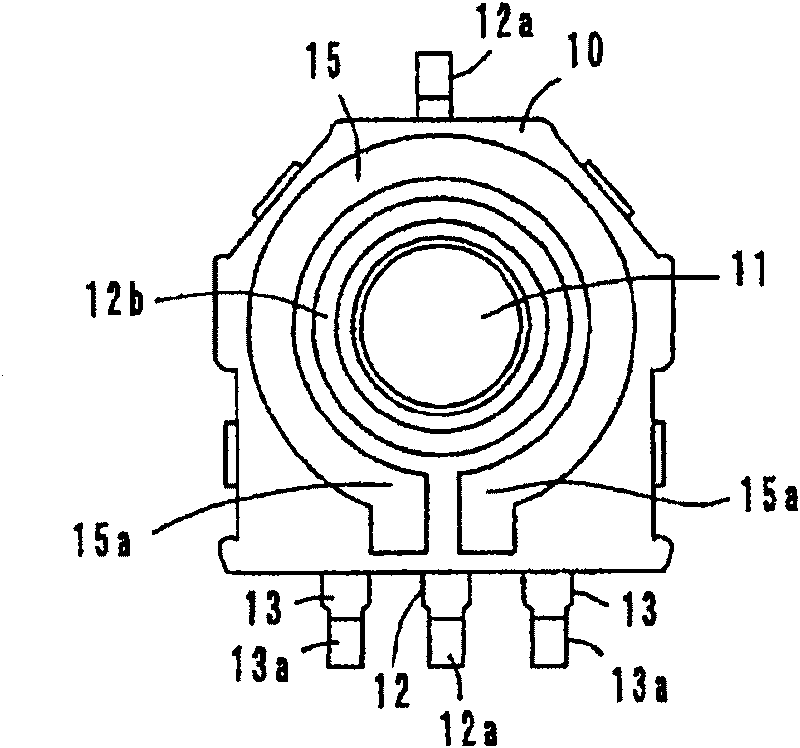

[0028] First refer to Figure 1 ~ Figure 4 One embodiment of a variable resistor related to the present invention and its structure will be described.

[0029] This varistor includes a resistor substrate 10 made of a resin molded product, a cover layer 20 made of a resin molded product, and a shaft 30 made of a resin molded product including a slider 35 . The substrate 10 has a central hole 11, and the terminals 12, 13 are embedded therein. End portions 12 a of terminals 12 protrude from the side surfaces of substrate 10 , and central portions are exposed on the surface of substrate 10 as annular current collectors 12 b. End 13a of terminal 13 (refer to Figure 4 ) protrudes from the side of the substrate 10, and the other end 13b is exposed on the surface of the substrate 10.

[0030] Su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com