Surgical sewing wire for medical use

A technology of surgical sutures and sutures, which is applied in the field of carbon fiber, can solve the problems of low price for patients, high cost of sutures, complicated manufacturing process, etc., and achieve the effects of wide application range, low cost and standardized processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

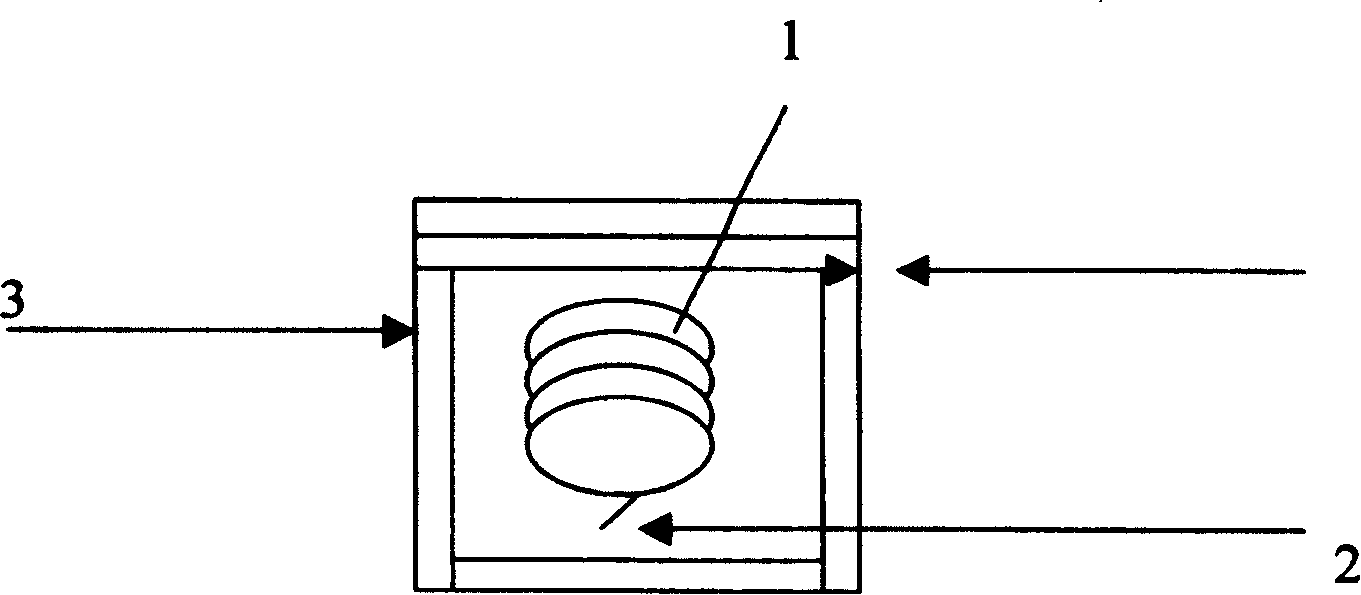

[0007] exist figure 1 In the three-dimensional schematic diagram of a medical surgical suture that replaces traditional medical surgical suture with carbon fiber, the medical surgical suture is mainly composed of a sterile winding shaft 1, a carbon fiber medical surgical suture 2, and a sterile packaging box 3. Polyacrylonitrile-based (PAN) carbon fiber with a carbon content of more than 99.998 is screened as sutures for medical operations. At the same time, it is processed according to the requirements of medical specifications and quality standards. After disinfection, dust removal, sterilization, and vacuum sterilization, it is wound on a sterile winding shaft. on, and then packed in aseptic packaging boxes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com