Method and apparatus for endpoint detection using partial least squares

A technology of endpoints and equipment, applied in the field of endpoint detection, which can solve problems such as strict requirements and lack of mathematics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

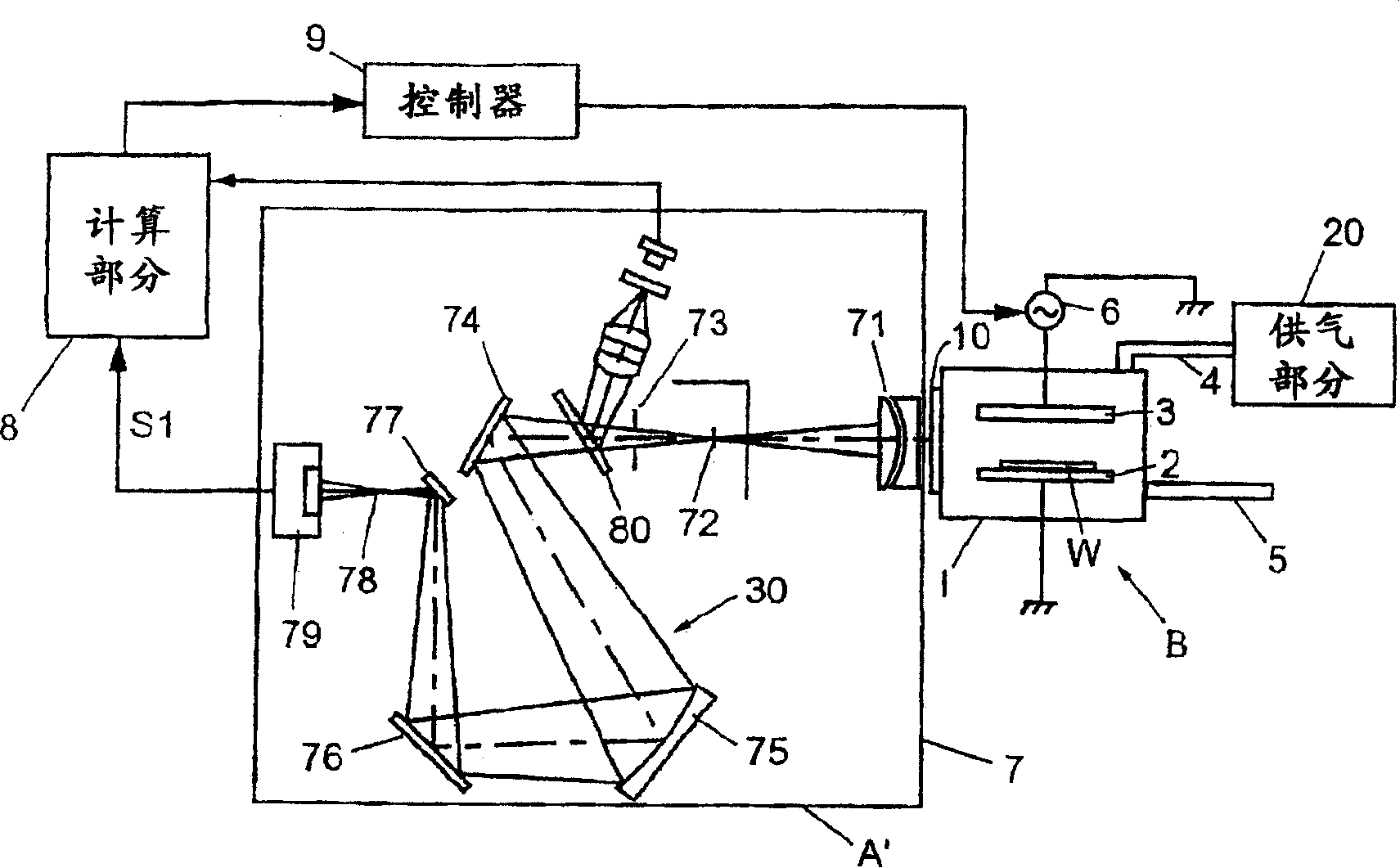

[0034] As noted above, the present inventors have recognized problems with conventional fabrication of reaction chambers and methods of using those reaction chambers that can be addressed by use of the present invention. Accordingly, the present invention provides an improved apparatus and method for endpoint detection that overcomes the disadvantages associated with conventional processing chambers.

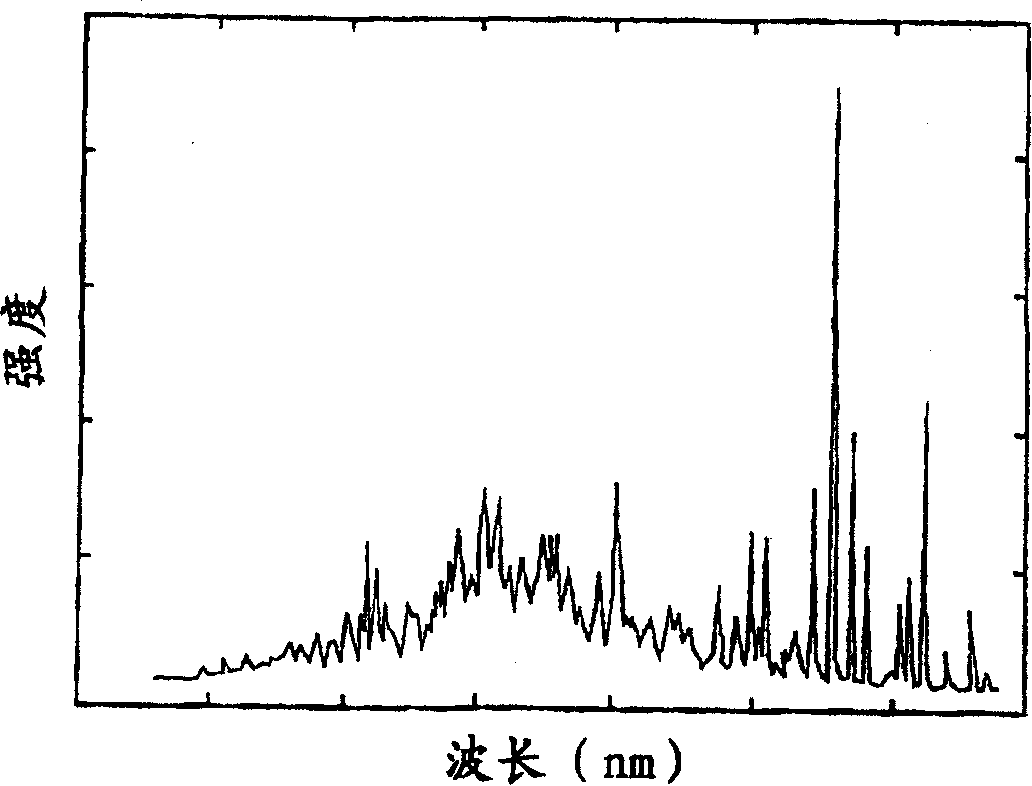

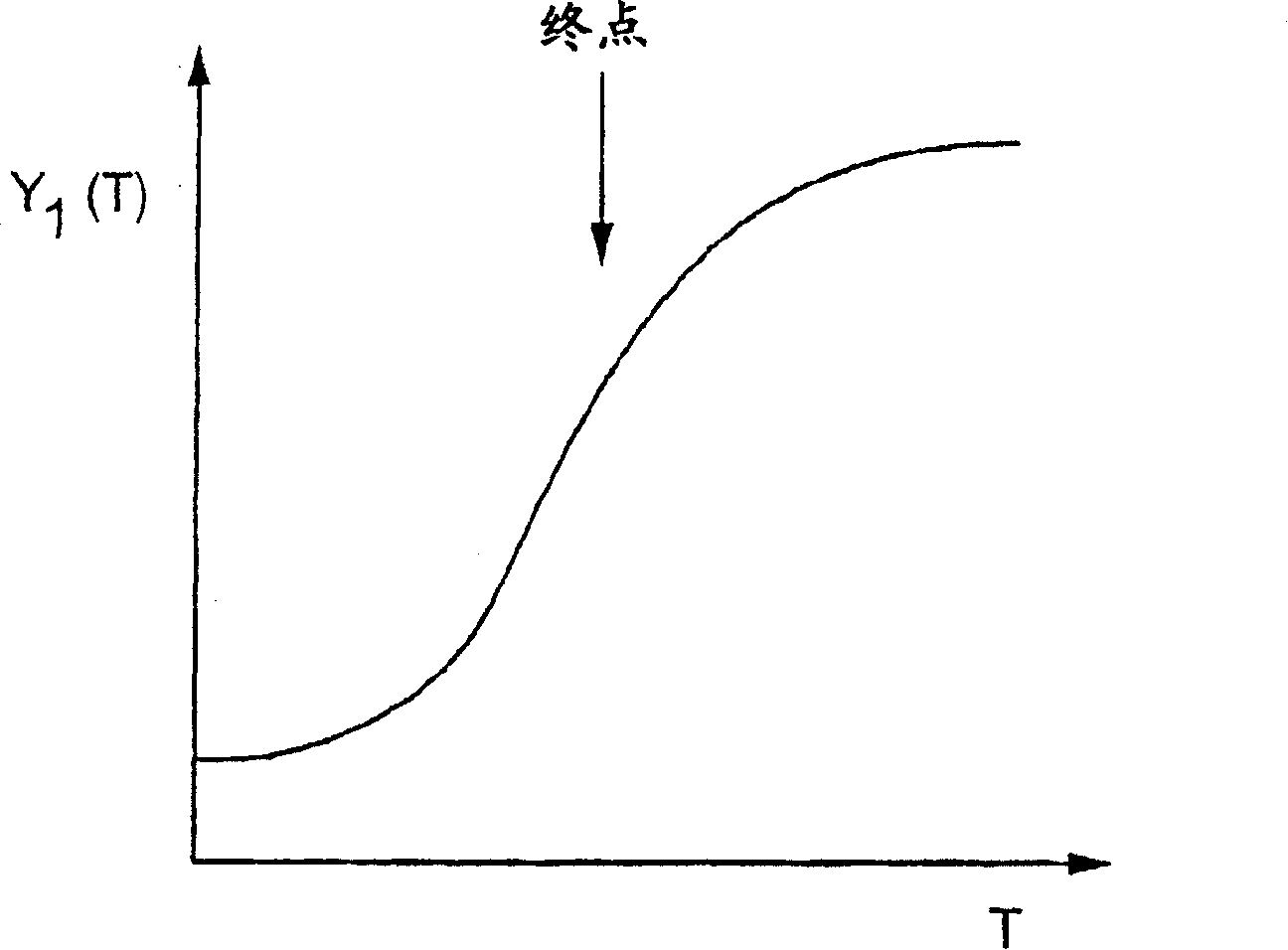

[0035] The inventors have recognized that it is difficult to accurately detect the endpoint of an etch process for a substrate with a small opening area. As the device size decreases, the opening area decreases, and the endpoint signal and signal-to-noise ratio decrease accordingly. What is needed is a simplified multivariate analysis method for selecting endpoint signals using known physical criteria set by the etch process.

[0036] In addition, the inventors have realized that it is difficult to repeatedly detect the endpoint for the etch process of different wafers. The en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com