Video camera rating data collecting method and its rating plate

A technology of camera calibration and calibration data, which is applied in the field of calibration boards, can solve problems such as poor accuracy of self-calibration algorithms, and achieve the effects of strong versatility, simple production, and simple operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

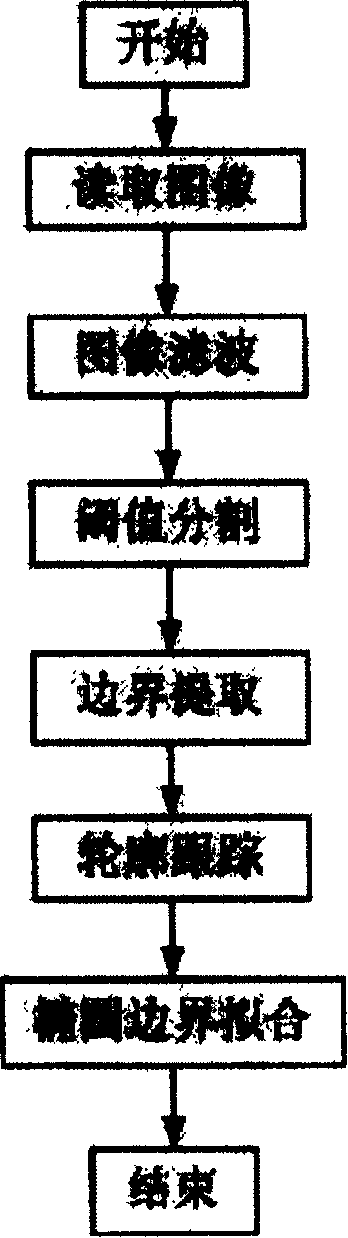

[0034] A method for collecting camera calibration data for collecting calibration data in a camera calibration process:

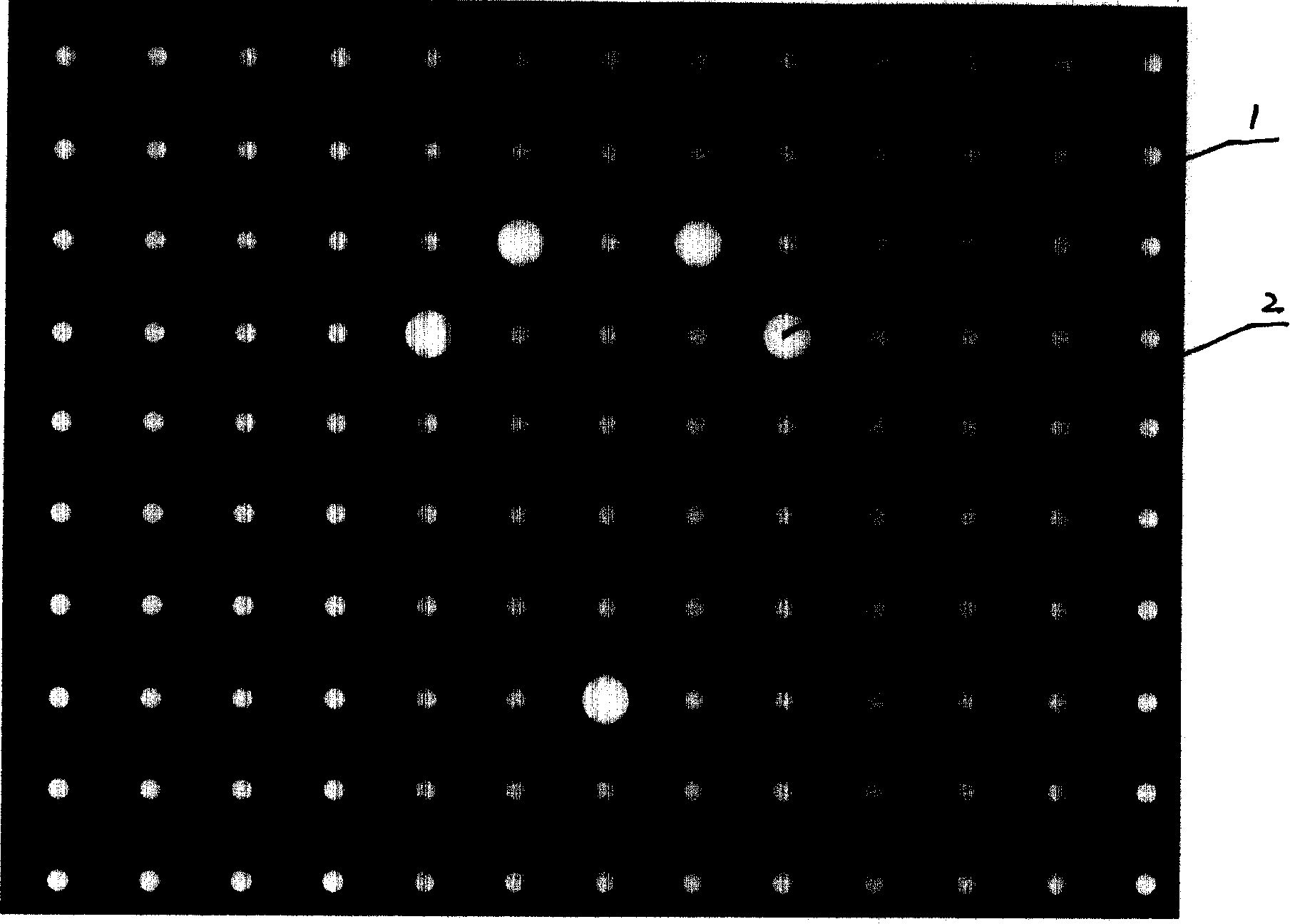

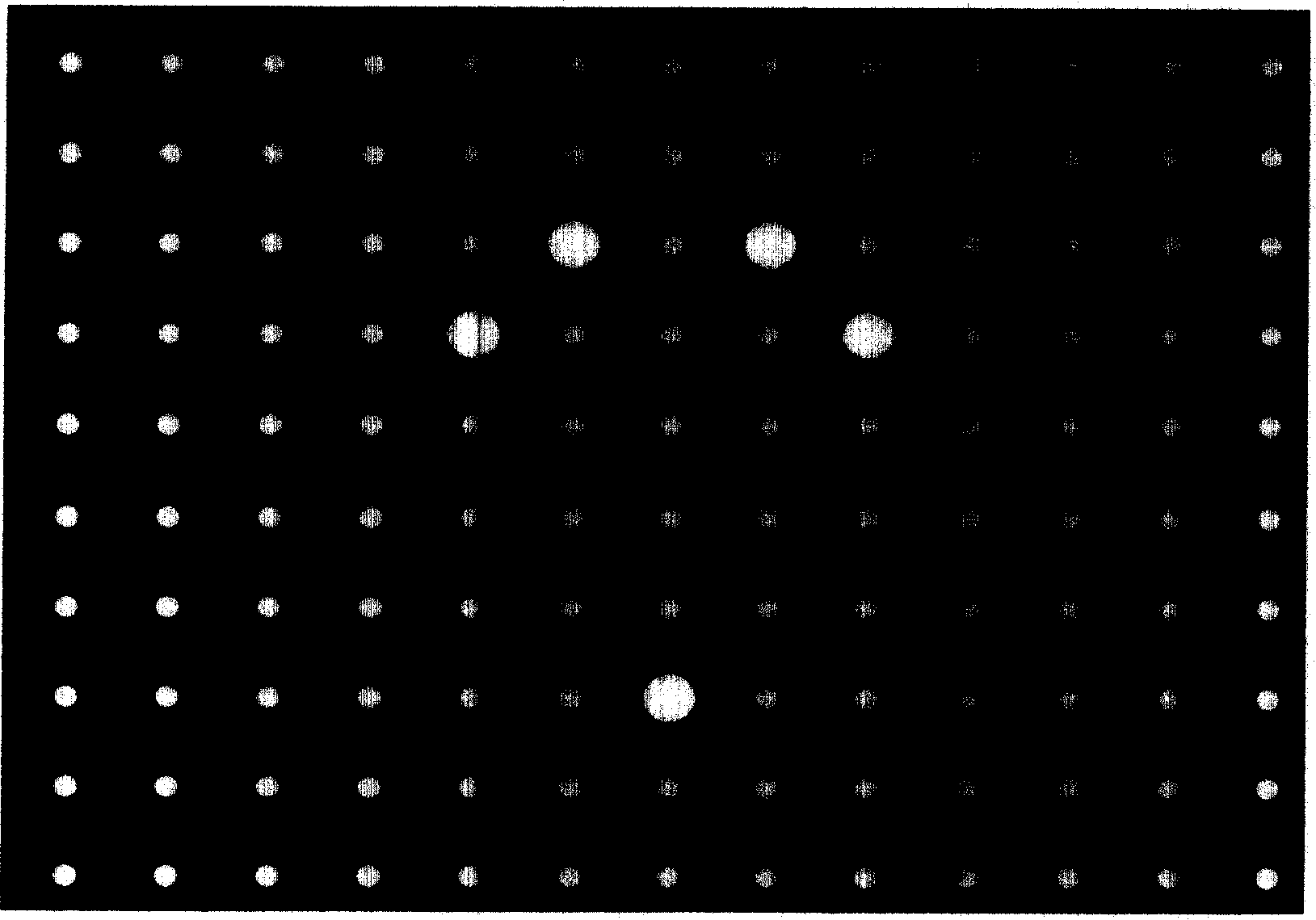

[0035] The first step: first set the mark dots distributed in an array on the calibration board, and select five mark dots as the feature mark dots, expand the above five feature mark dots, so that the above five feature mark dots If the diameter is larger than the remaining mark dots except the above five characteristic mark dots, one of the above five mark dots as characteristic mark dots shall be used as a reference feature mark dot, and the reference feature mark The dot has the distance from the reference characteristic mark dot to other characteristic mark dots greater than the distance between any two characteristic mark dots and the connection line between the reference characteristic mark dot and other characteristic mark dots The included angle between them is greater than 3 degrees, two of the four characteristic mark dots other than the above-me...

Embodiment 2

[0040]A calibration board used for the acquisition method of camera calibration data, which includes a calibration board plate 1, on which a mark dot 2 is arranged on the calibration plate plate 1, and the mark dots 2 are distributed in an array on the calibration plate plate 1. Among the mark circles 2, 5 mark circles are characteristic mark circles, whose diameter is larger than the other mark circles 2, and one of the 5 characteristic mark circles is a reference feature mark circle, and the reference feature mark circle The distance between the point and other characteristic mark circles is greater than the distance between any two characteristic mark circles, and the angle between the lines connecting the reference feature mark circle and other mark circles is greater than 3 degrees. Among them, the calibration board plate 1 is a blackboard, and the mark dot 2 is a white solid circle.

[0041] The following is a more detailed description of the specific embodiments of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com