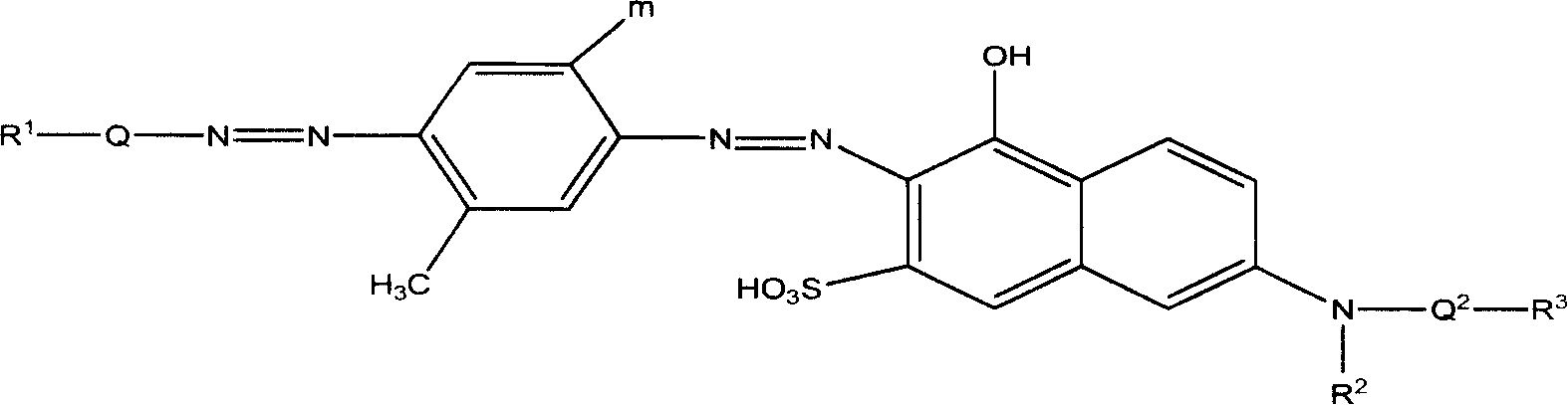

Preparation technology of direct mixed spinning purple dyestuff

A preparation process and a technology of dyes, which are applied in disazo dyes, dyeing methods, textiles and papermaking, and can solve the problems that the final dyes are difficult to meet the use requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] A kind of preparation technology of direct blending violet dye, comprises following operation

[0031] Diazo reaction: Mix 30.3 parts by weight of 2-naphthylamine-4,8-disulfonic acid with 300 parts by weight of water, add sodium carbonate to neutralize to PH=7-7.5, lower the temperature to 0-5°C, add hydrochloric acid 28 parts by weight, then add 6.9 parts by weight of sodium nitrite, mix well, and react to the end after 2 hours to generate diazonium salt.

[0032] Coupling reaction: Mix and dissolve 14 parts by weight of 2-methoxy-5-methylaniline with a mixture of 200 parts by weight of water and 14 parts by weight of hydrochloric acid at 50°C, then cool down to 35°C, and then slowly dissolve the solution Add it to the diazonium salt generated in the diazonium reaction process, and carry out the coupling reaction at a temperature of 10-20 ° C. After 1 hour, use dilute sodium carbonate solution to adjust the pH to 4. After continuing the reaction for 2 hours, add dilute...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com