A kind of preparation method of monofunctional branched polyethylene glycol

A polyethylene glycol and functionalization technology, applied in the field of preparation of single functionalized branched polyethylene glycol, can solve the problem of end group modification rate (substitution rate, limitation of functionalization rate, difficulty in separation and purification, large steric hindrance) And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

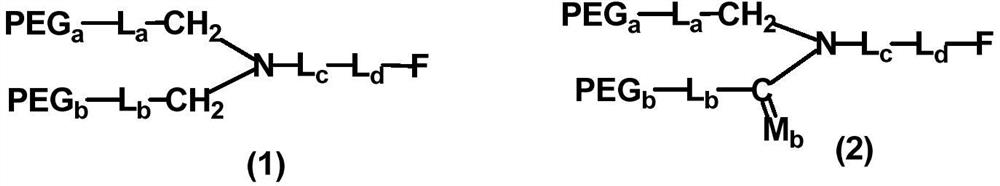

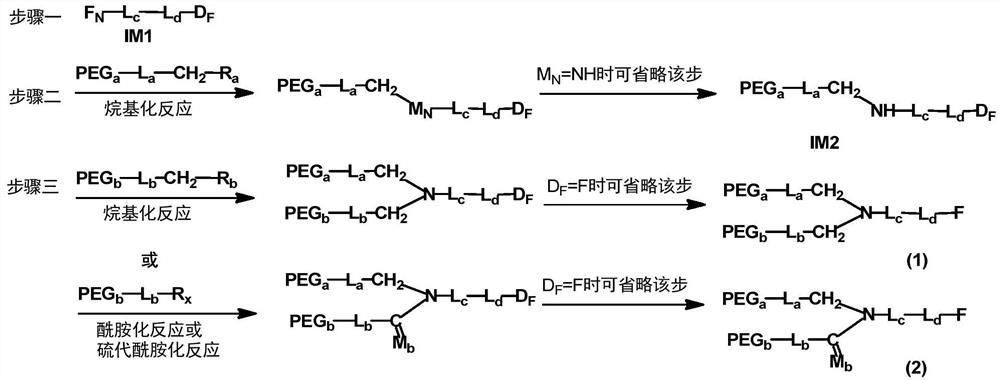

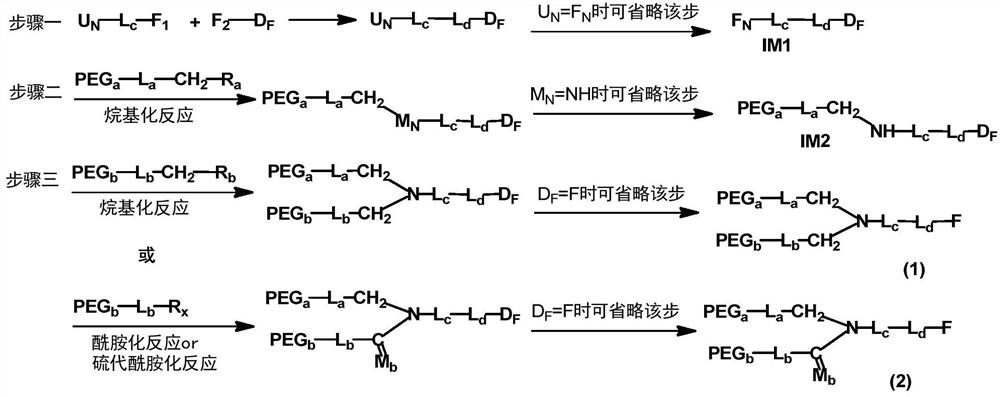

[0103] The present invention provides a kind of preparation method of single functionalization branched polyethylene glycol, it is realized by following technical scheme: The structure of described single functionalization branched polyethylene glycol is as general formula (1) or general formula ( 2) as shown:

[0104]

[0105] Among them, PEG a 、PEG b Be the same or different polyethylene glycol components, each independently, all by C 1~20 The terminal oxygen atom of the hydrocarbyl-linked PEG component; L a , L b For the same or different divalent linking groups, independent of each other, respectively connected to PEG a 、PEG b the other oxygen end of the M b is an oxygen atom or a sulfur atom; L c is a carbon chain linking group; L d It is a divalent linking group containing a covalent linking group generated by a coupling reaction; the group F contains a functional end group R 01 ; 01 with L d Directly connected, or connected through a divalent linker Z;

...

Embodiment 1

[0532] Embodiment 1 branched polyethylene glycol propionaldehyde

[0533] The functionalized polyethylene glycol monomethyl ether with a molecular weight of 20kDa is used as a raw material to prepare branched polyethylene glycol propionaldehyde with a molecular weight of about 40kDa.

[0534] (1) Branched polyethylene glycol propionaldehyde with asymmetric structure (the linking group between the two PEG components and the N branching center is different)

[0535]

[0536] Corresponding to general formula (2), where, L a , L b is methylene, M b is an oxygen atom, L c is methylene, L d is an amide bond (-CONH-), F is a propionaldehyde group (-CH 2 CH 2 CHO, wherein, Z is ethylene, R 01 for -CHO). Design two mPEG (CH 3 O(CH 2 CH 2 O) n -) The molecular weight is about 20kDa.

[0537] The reaction formula is as follows:

[0538]

[0539] The preparation process is as follows:

[0540] Step a: Dissolve 10g (47.8mmol) of benzyloxycarbonyl-protected glycine (S1-...

Embodiment 2

[0554] Embodiment 2 branched polyethylene glycol propionaldehyde (one-step coupling method)

[0555]

[0556] Corresponding to general formula (1), where, L a , L b is methylene, L c is methylene, L d is an amide bond (-CONH-), F is a propionaldehyde group (-CH 2 CH 2 CHO, wherein, Z is ethylene, R 01 for -CHO). Both mPEGs were designed to have a molecular weight of approximately 10 kDa.

[0557] The preparation process is as follows:

[0558] Steps a~b: Repeat steps a~b in Example 1(1). The amino acetal intermediate S1-3 (7.3 g, yield 92%) was obtained.

[0559] Step c: Using the preparation method of Example 1 (1) step c, using 10kDa, PDI = 1.01 methoxypolyethylene glycol as a raw material to obtain about 44g of methoxypolyethylene glycol mesylate mPEG-OMs .

[0560] Using the alkylation conditions of Example 1 (1) step c, 2mmol of amino acetal intermediate S1-3 and excess methoxypolyethylene glycol methanesulfonate (8mmol) undergo alkylation reaction, membrane...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| number average molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com