Oblique cam type torsional vibrator for vibrating hole formation

A technology of torsional vibration and inclined cam, which is applied in the direction of driving devices, manufacturing tools, portable drilling rigs, etc., can solve the problems of unbalanced vibration force, high sub-structure gap impact and vibration, affecting the service life of the system, and unable to adjust the amplitude. The effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described in detail below in conjunction with the accompanying drawings.

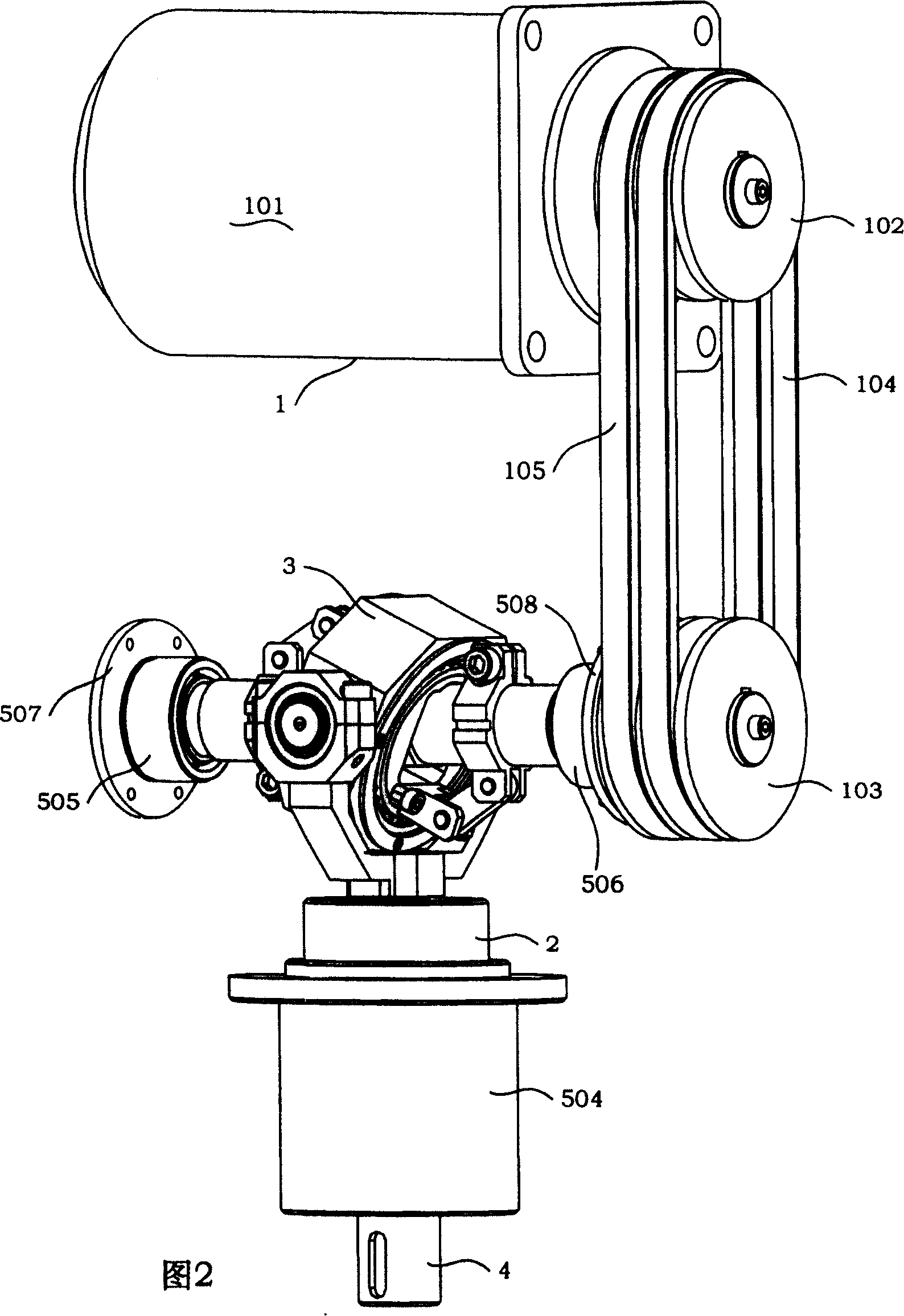

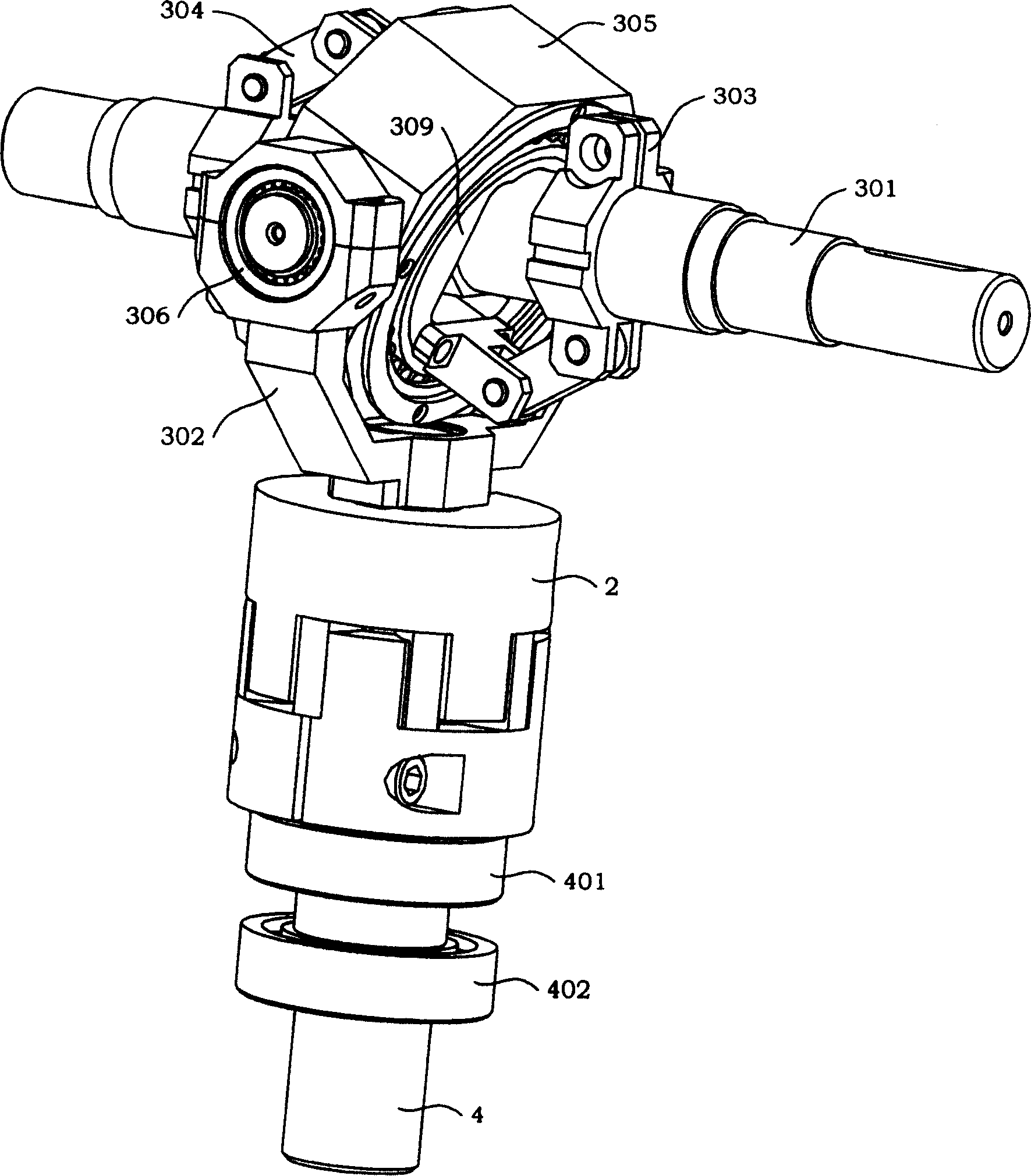

[0017] The present invention is an oblique cam type torsional vibrator for vibratory tapping and vibratory reaming, which consists of a housing, a drive assembly 1, an elastic coupling 2, a vibration generating assembly 3 and an output shaft 4;

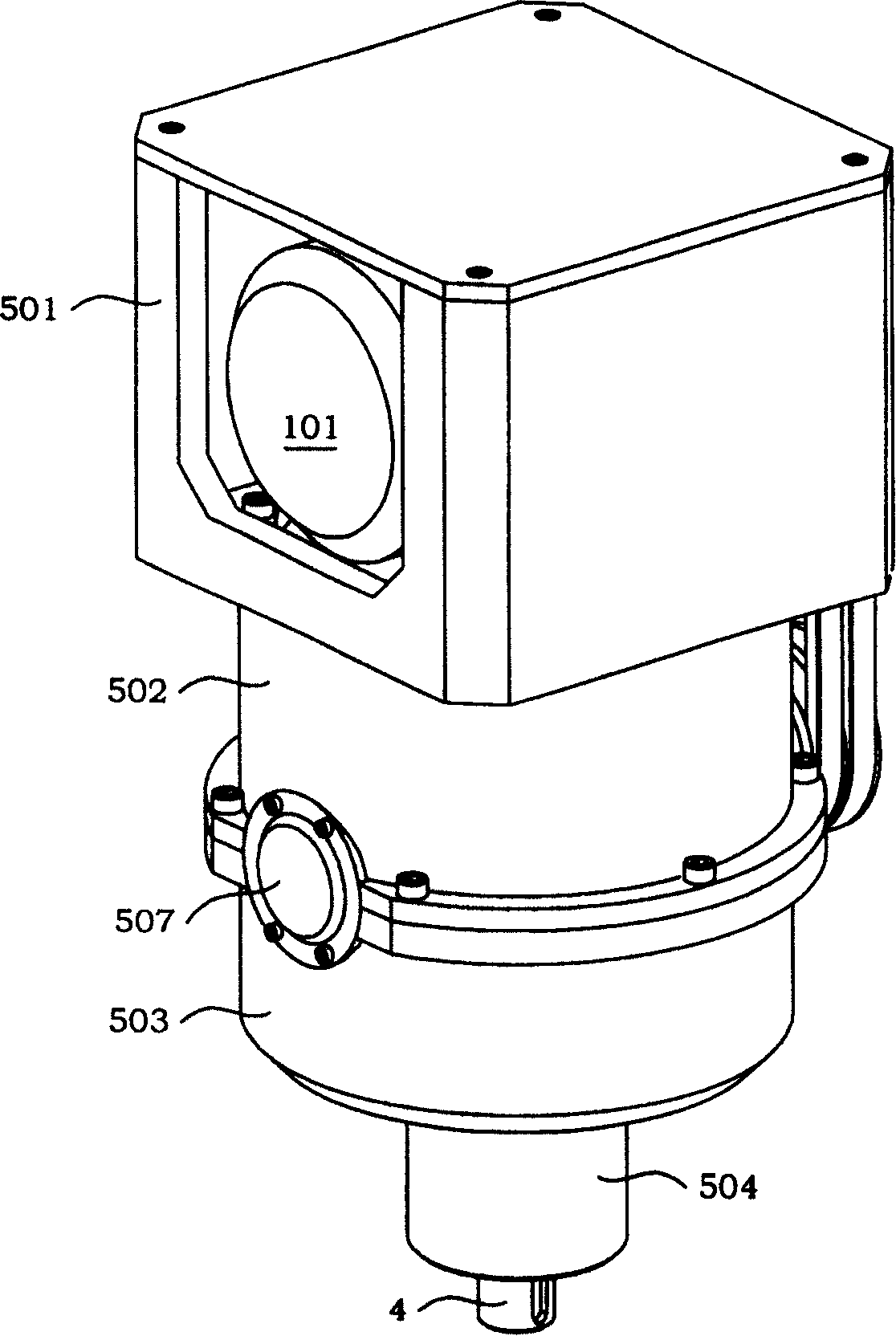

[0018] See figure 1 ,figure 2, image 3 As shown, the upper shell 502 and the lower shell 503 of the shell are fixed together by screws, and the left end cover 507 and the right end cover 508 are symmetrically installed at the junction, and the left end cover 507 is equipped with a left bearing 505 and a right end cover 508. A right bearing 506 is installed inside, one end of the transmission shaft 301 is installed in the left bearing 505, the other end of the transmission shaft 301 is installed in the right bearing 506, and the left bearing 505 and the right bearing 506 support the transmission shaft 301; The lowe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com