Beta'-Sialon whisker gas phase reaction preparation method

A gas phase reaction and whisker technology, applied in the field of ceramic materials, to achieve high temperature chemical stability, complete crystal structure, and good chemical stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The process steps are as follows:

[0027] (1) Ball milling: finely grind the raw materials until the particle size of the raw materials reaches below 74 μm;

[0028] (2) Sieving: in order to ensure the average particle size and particle size distribution of the powder, use a 74 μm standard sieve to sieve the raw material powder with a relatively dispersed particle size;

[0029] (3) Batching: 26.85wt% by silica fume, 47.39wt% bauxite, and 25.76wt% carbon black;

[0030] (4) Wet mixing: The prepared mixture is ball milled and mixed with absolute ethanol as the medium, and the wet mixing time is 18 hours:

[0031] (5) Drying: put the wet-mixed slurry into an oven and dry at 80°C;

[0032] (6) Dry mixing: the mixture is fully dried and then ball milled and dry mixed for 6 hours to ensure that the mixture is fully uniform;

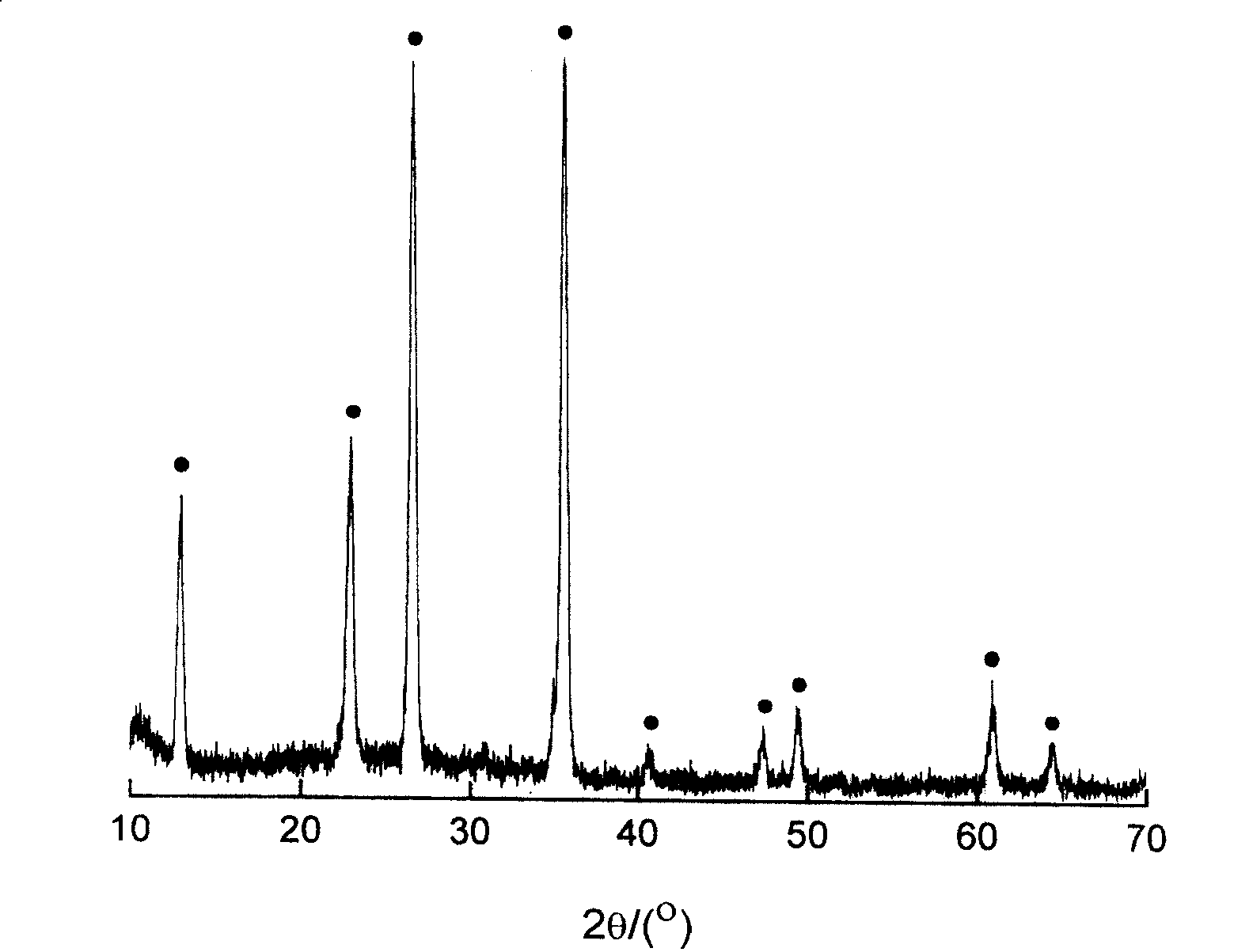

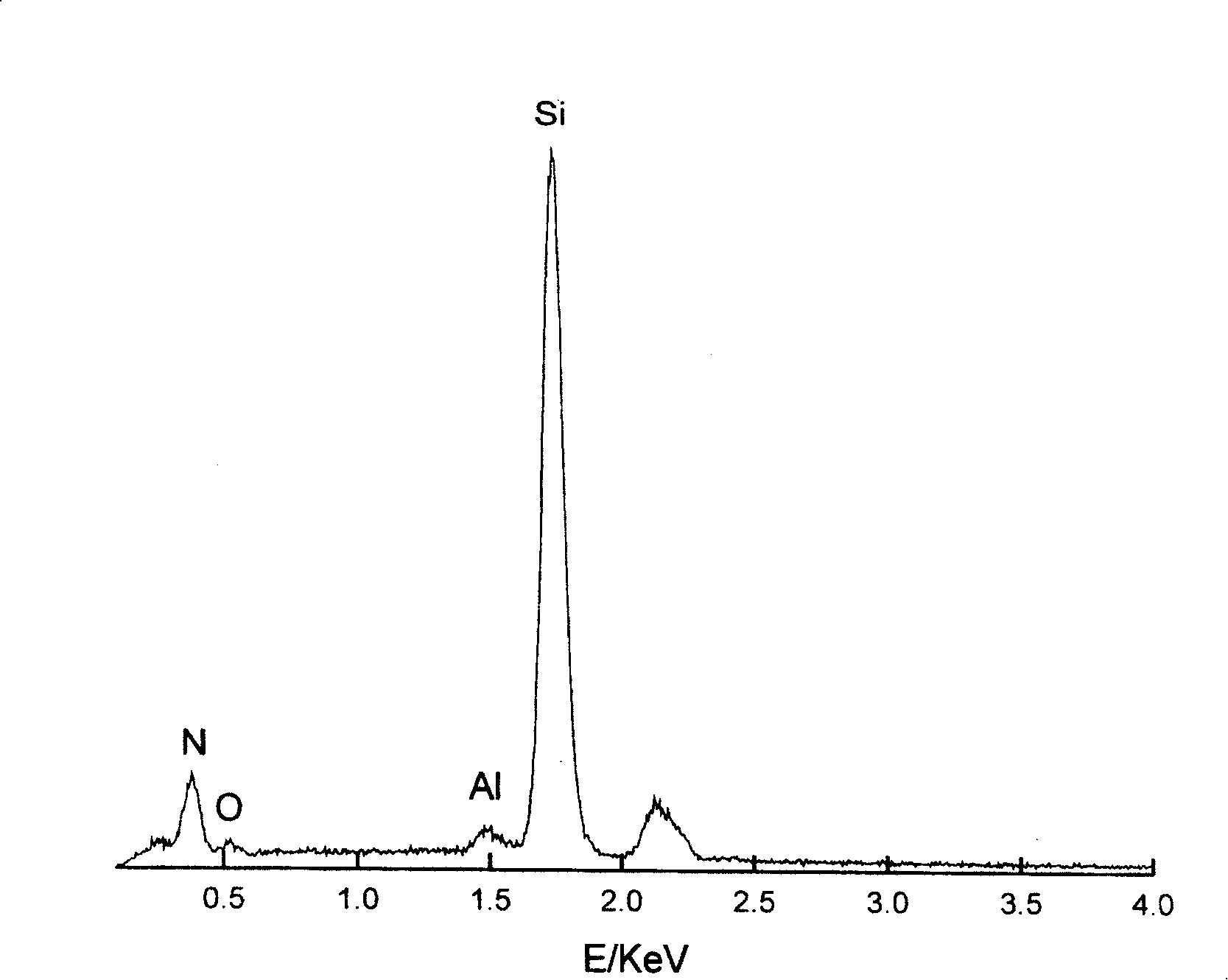

[0033] (7) High-temperature gas-phase synthesis: put the mixture into a porous graphite crucible and place it in a vertical MoSi 2 High temperatur...

Embodiment 2

[0036] The process steps are as follows:

[0037] (1) Ball milling: finely grind the raw materials until the particle size of the raw materials reaches below 74 μm;

[0038] (2) Sieving: in order to ensure the average particle size and particle size distribution of the powder, use a 74 μm standard sieve to sieve the raw material powder with a relatively dispersed particle size;

[0039] (3) Batching: 52.64wt% of silica fume, 23.21wt% of bauxite, and 24.15wt% of carbon black;

[0040] (4) Wet mixing: place the prepared mixture in a polyurethane ball mill tank, and use absolute ethanol as a medium for ball milling and mixing, and the wet mixing time is 24 hours;

[0041] (5) Drying: put the wet mixed slurry into an oven and dry at 60°C;

[0042] (6) Dry mixing: the mixture is fully dried and then ball milled and dry mixed for 4 hours to ensure that the mixture is fully uniform;

[0043] (7) High-temperature gas-phase synthesis: put the mixture into a porous graphite crucible ...

Embodiment 3

[0046] The process steps are as follows:

[0047] (1) Ball milling: finely grind the raw materials until the particle size of the raw materials reaches below 74 μm;

[0048] (2) Sieving: in order to ensure the average particle size and particle size distribution of the powder, use a 74 μm standard sieve to sieve the raw material powder with a relatively dispersed particle size;

[0049] (3) Batching: 47.78wt% by silica fume, 21.07wt% bauxite, and 31.15wt% carbon black;

[0050] (4) Wet mixing: the prepared mixture is ball milled and mixed with absolute ethanol as the medium, and the wet mixing time is 20 hours;

[0051] (5) Drying: put the wet mixed slurry into an oven and dry at 70°C;

[0052] (6) Dry mixing: the mixture is fully dried and then ball milled and dry mixed for 5 hours to ensure that the mixture is fully uniform;

[0053] (7) High-temperature gas-phase synthesis: put the mixture into a porous graphite crucible and place it in a vertical MoSi 2 High temperature ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com