Technology method of artificial frozen soil control blasting by deep surface forzen method

A technology of artificial frozen soil and controlled blasting, applied in blasting and other directions, can solve the problems of high labor intensity of workers, difficulty in manual excavation, and difficulty in excavation, and achieve the effect of reducing unit consumption of explosives, reducing labor intensity of workers, and being beneficial to safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

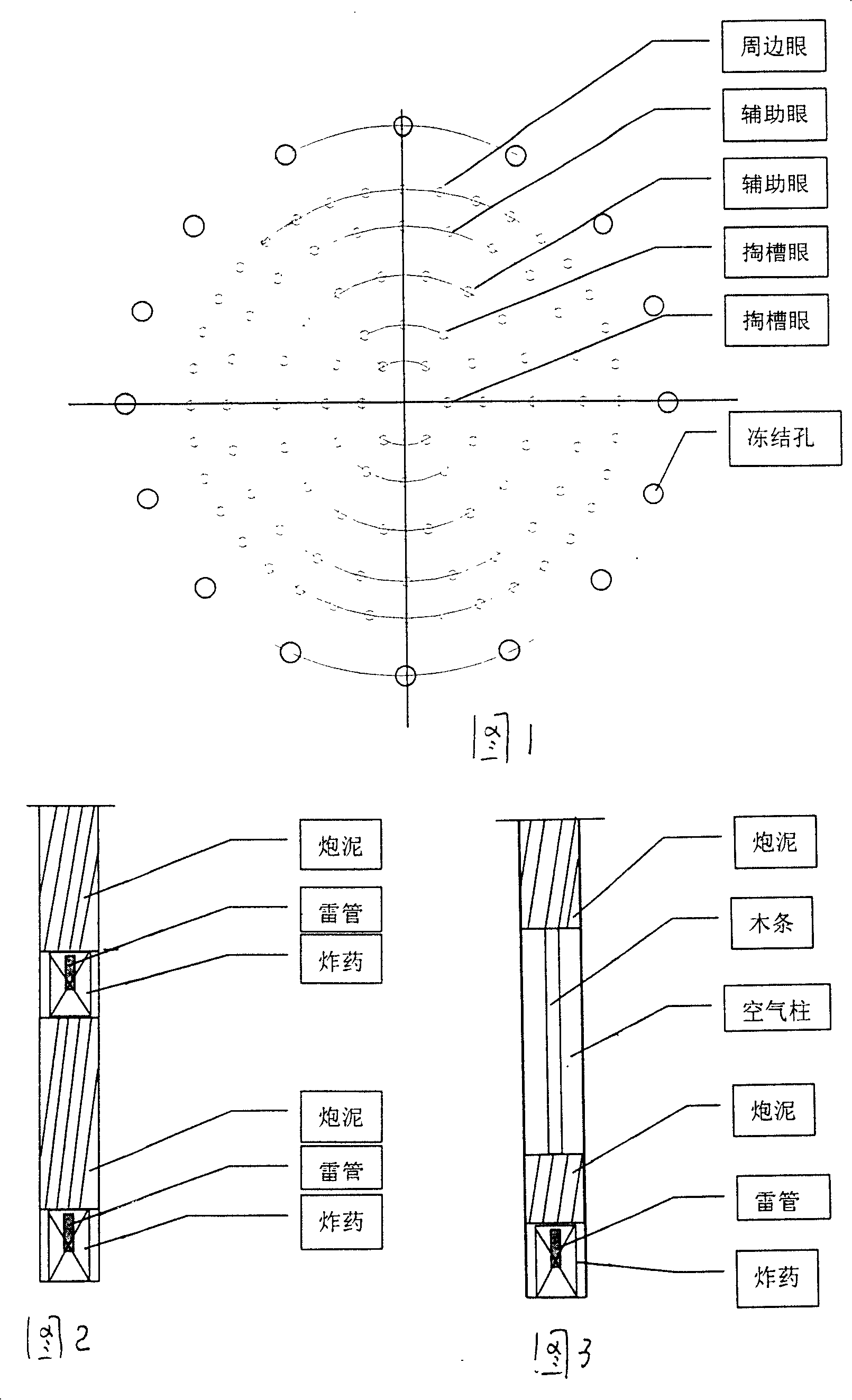

[0024] The present invention will be described in detail below through engineering embodiments in conjunction with the accompanying drawings.

[0025] Project Overview

[0026] A coal mine is developed for a vertical shaft. The net diameter of the main shaft is 4.5m. The shaft passes through the Quaternary topsoil layer with a thickness of 289m. The topsoil section is constructed by freezing method, and the freezing depth is 320m. The diameter of the upper excavation barren is 6.1m. When the shaft is excavated to a depth of 110m, the entire section of the shaft is frozen solid. Since the depth of the well is between 100m and 150m, it is mainly a white-gray calcareous clay layer, which has a high strength after being frozen. Manual excavation of the working face is very difficult, the footage of a shift is 200mm, the labor intensity of the workers is very high, and the efficiency is extremely low. In order to reduce the labor intensity of workers and speed up the excavation, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com