Nanometer aquogel with both pH and temperature sensitivity and its preparation process

A nano-hydrogel and surfactant technology, which is applied in the field of environment-sensitive polymer nanomaterials, can solve the problems of not reaching the nanometer level, limited application, single sensitive type, etc., and achieves rapid response capability and simple synthesis process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

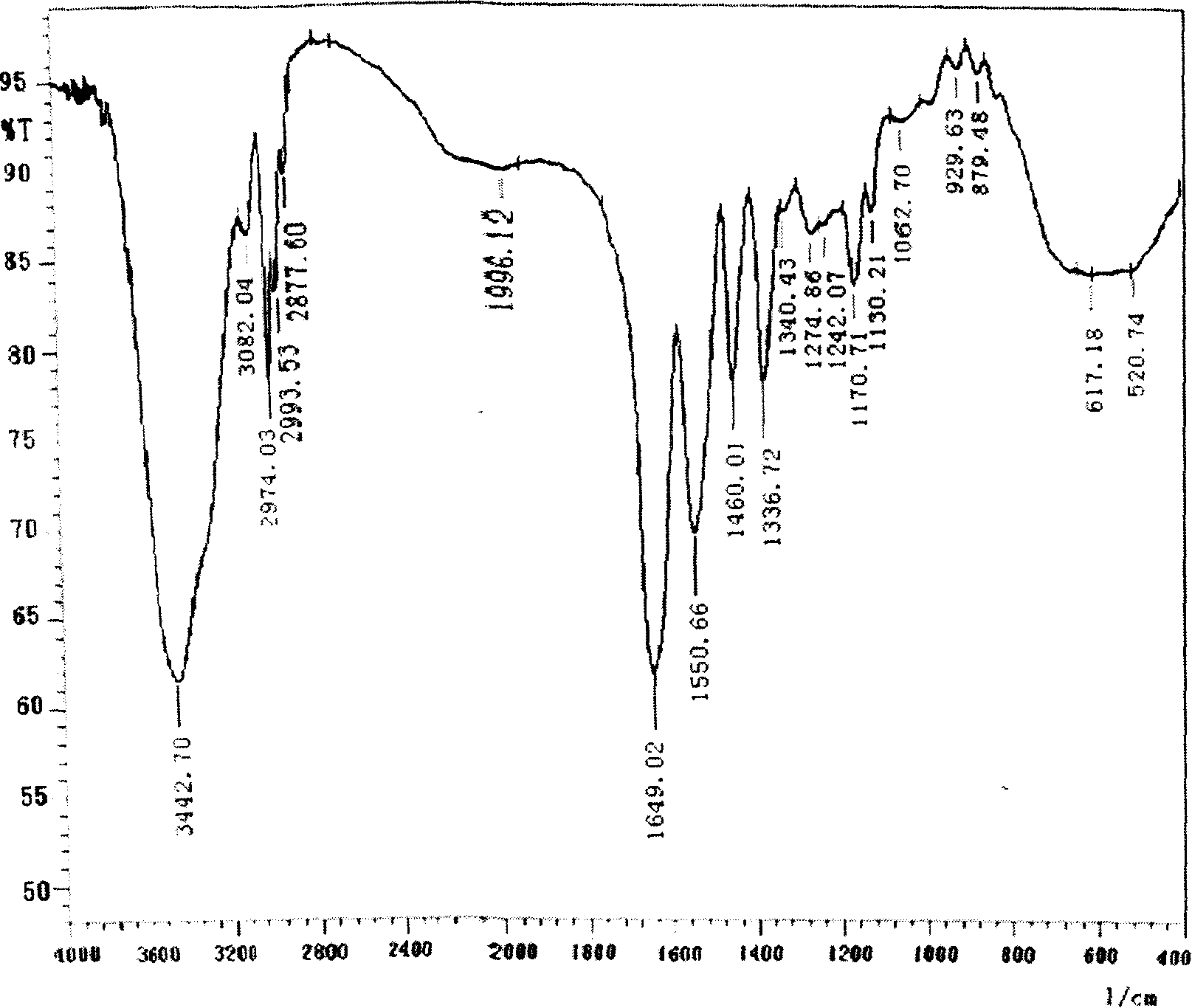

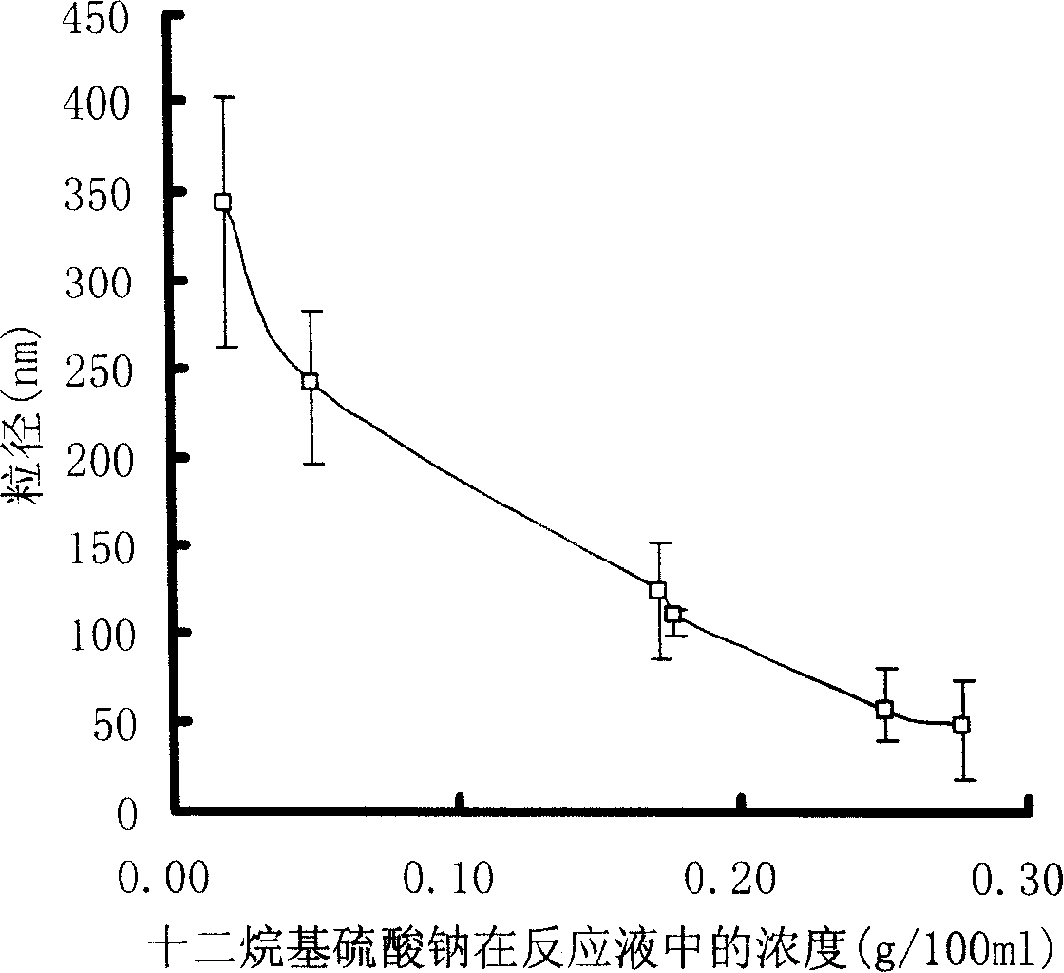

[0038] Dissolve 3.7770g of N-isopropylacrylamide, 0.18mL of acrylic acid, 0.0690g of N,N'-methylenebisacrylamide, 0.3366g of dodecylsulfuric acid in 230mL of aqueous solution and add to the have N 2 Catheter in a 500mL three-neck flask. Stir at a rate of 400 rpm, and feed N 2 After fully deoxidizing, heat with a water bath. Add 0.0624 g of an aqueous solution of potassium persulfate, adjust the volume of the reaction solution to 370 mL, and react at 70° C. for 4 h. The product obtained is fully dialyzed with distilled water (dialysis bag, molecular weight cut-off is 10,000), and then freeze-dried to obtain a PNIPAM-co-AA (acrylic acid) nano-hydrogel with a particle size of 110nm ± 15nm. The LCST is 35°C. Infrared spectrogram see figure 2 .

Embodiment 2

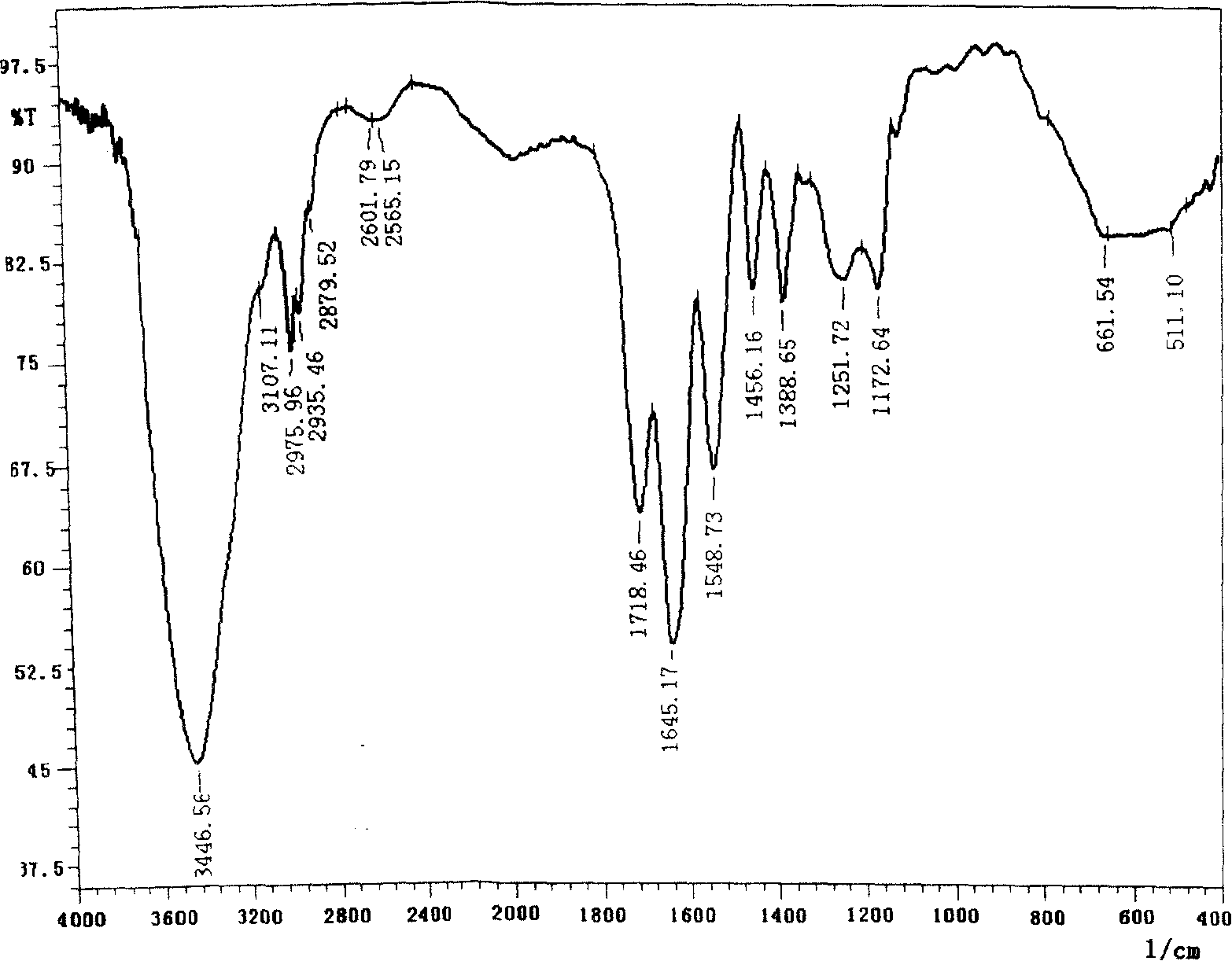

[0040] Dissolve 3.7770g of N-isopropylacrylamide, 0.81mL of acrylic acid, 0.0690g of N,N'-dodecylmethylenebisacrylic acid amine, and 0.6366 octaalkyl sodium sulfate in 230mL of aqueous solution, and add an electric stirring device, a thermometer and equipped with N 2 Catheter in a 500mL three-neck flask. Stir at a rate of 400 rpm, and feed N 2 After fully deoxidizing, heat with a water bath. Add 0.0624g of an aqueous solution of ammonium persulfate, adjust the volume of the reaction solution to 370mL, and react at 70°C for 4h. The obtained product was fully dialyzed with distilled water (dialysis bag, molecular weight cut-off is 10,000), and then freeze-dried to obtain a PNIPAM-co-AA (acrylic acid) nanohydrogel with a particle size of 48nm ± 10nm, and an LCST of 43.8°C.

Embodiment 3

[0042] Dissolve 3.7770g of N-isopropylacrylamide, 0.30mL of acrylamine, 0.0690g of N,N'-diallyl tartaric acid diamide, 0.6366g of sodium lauryl sulfate in 230mL of aqueous solution and add an electric stirring device, a thermometer and equipped with N 2 Catheter in a 500mL three-neck flask. Stir at a rate of 400 rpm, and feed N 2 After fully deoxidizing, heat with a water bath. Add 0.0624g of an aqueous solution of N,N,N'N'-tetramethylethylenediamine, dilute the reaction solution to 370mL, and react at 70°C for 4h. The obtained product was fully dialyzed with distilled water (dialysis bag, molecular weight cut-off is 10,000), and then freeze-dried to obtain PNIPAM-co-NH with a particle size of 95nm±10nm 2 (Acylamine) nanohydrogel, LCST is 39.3°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com