Liquid bearing module

A fluid bearing and bearing technology, applied in the direction of bearings, shafts and bearings, mechanical equipment, etc., can solve the problems of rotating parts and fluid bearing lubricating medium easily flowing to the outside of the fluid bearing, so as to prevent the shaft from detaching and prevent the flow to the outside of the fluid bearing. external effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

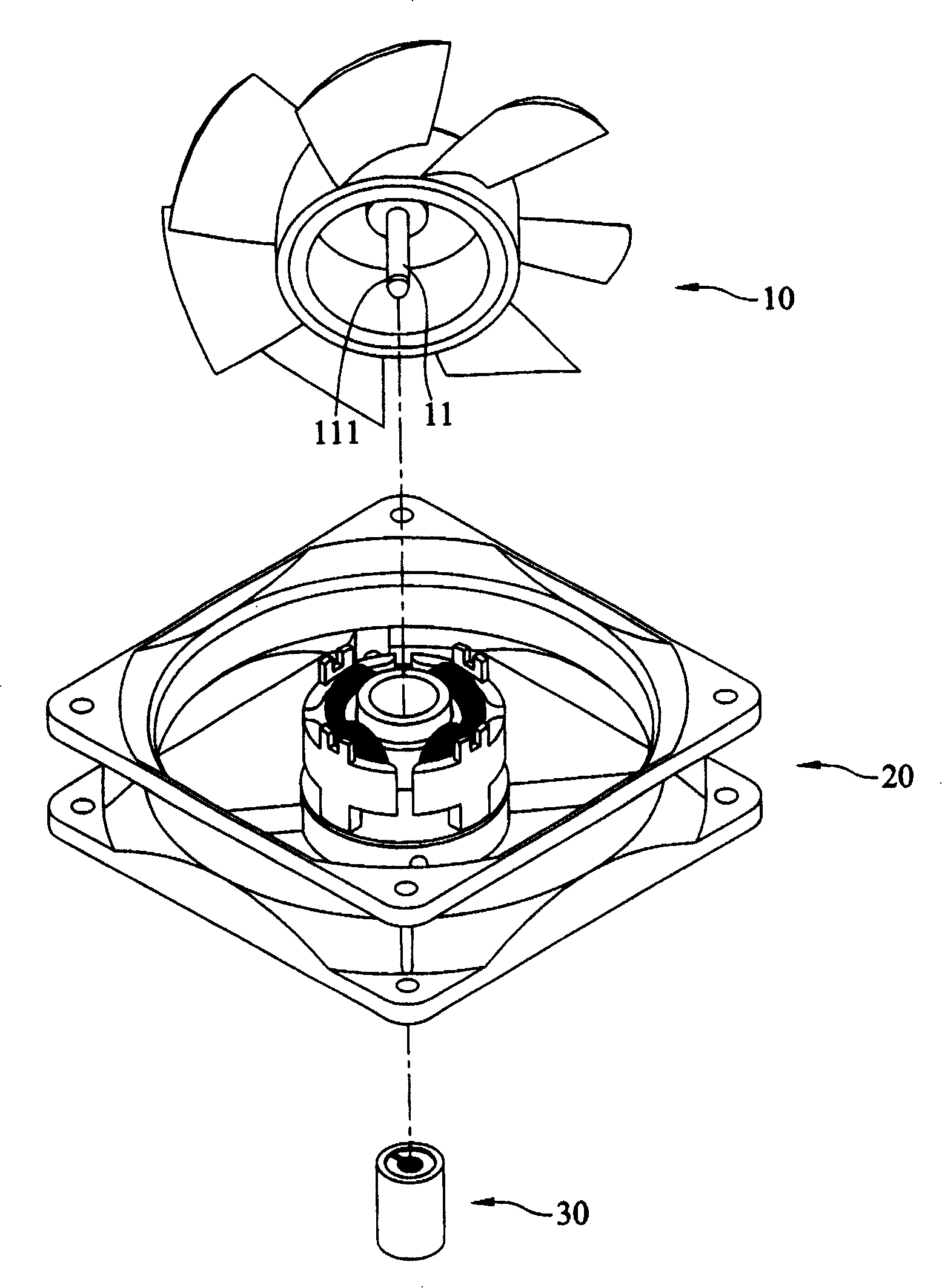

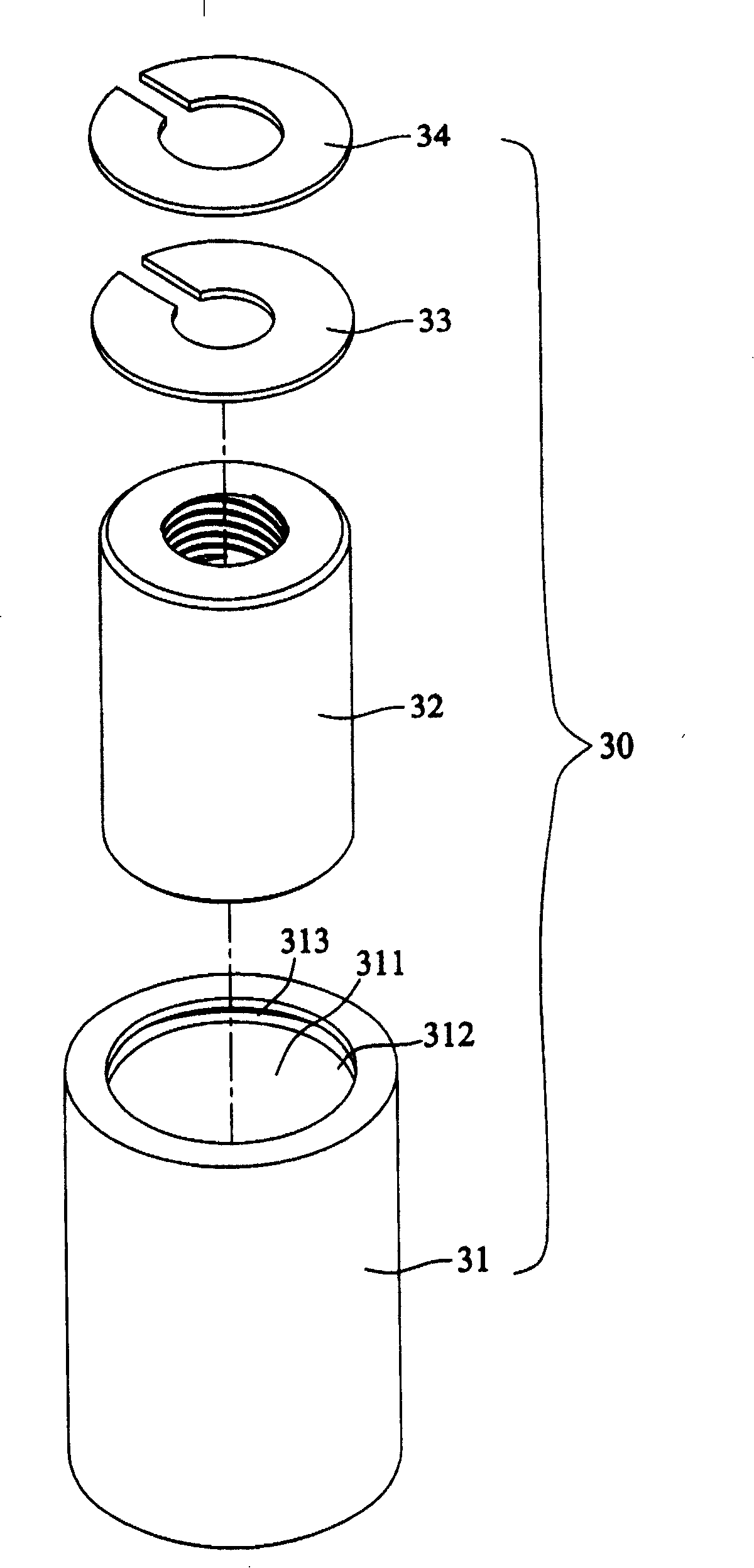

[0042] Such as image 3 As shown, a fluid bearing module 30 disclosed in the present invention is applied to an electric motor that outputs rotational kinetic energy such as a motor or a fan. Such as image 3 The fan shown includes a rotor part 10, a stator part 20 and a fluid bearing module 30, the rotor part 10 is arranged on the stator part 20 by using the fluid bearing module 30, and the rotor part 10 includes several blades arranged on the periphery, And the inner ring is provided with a permanent magnet, and is fixed on the center of the stator part 20 by using the shaft center 11 to install the fluid bearing module 30, and the stator part 20 has several magnetic poles formed by coils wound on several silicon steel sheets. After the current passes through the coil, the magnetic poles will generate magnetic force, so that the magnets correspond to the magnetic poles of the stator part 20. When the magnetic poles generate magnetic force, they will repel the magnets and make...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com