Pulley for drum washing machine

A drum washing machine and pulley technology, which is applied to other washing machines, washing devices, mechanical equipment, etc., can solve the problems of conveyor belt 106 vibration, abnormal noise, resonance, etc., and achieve the effects of improving processability, preventing resonance noise, and reducing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

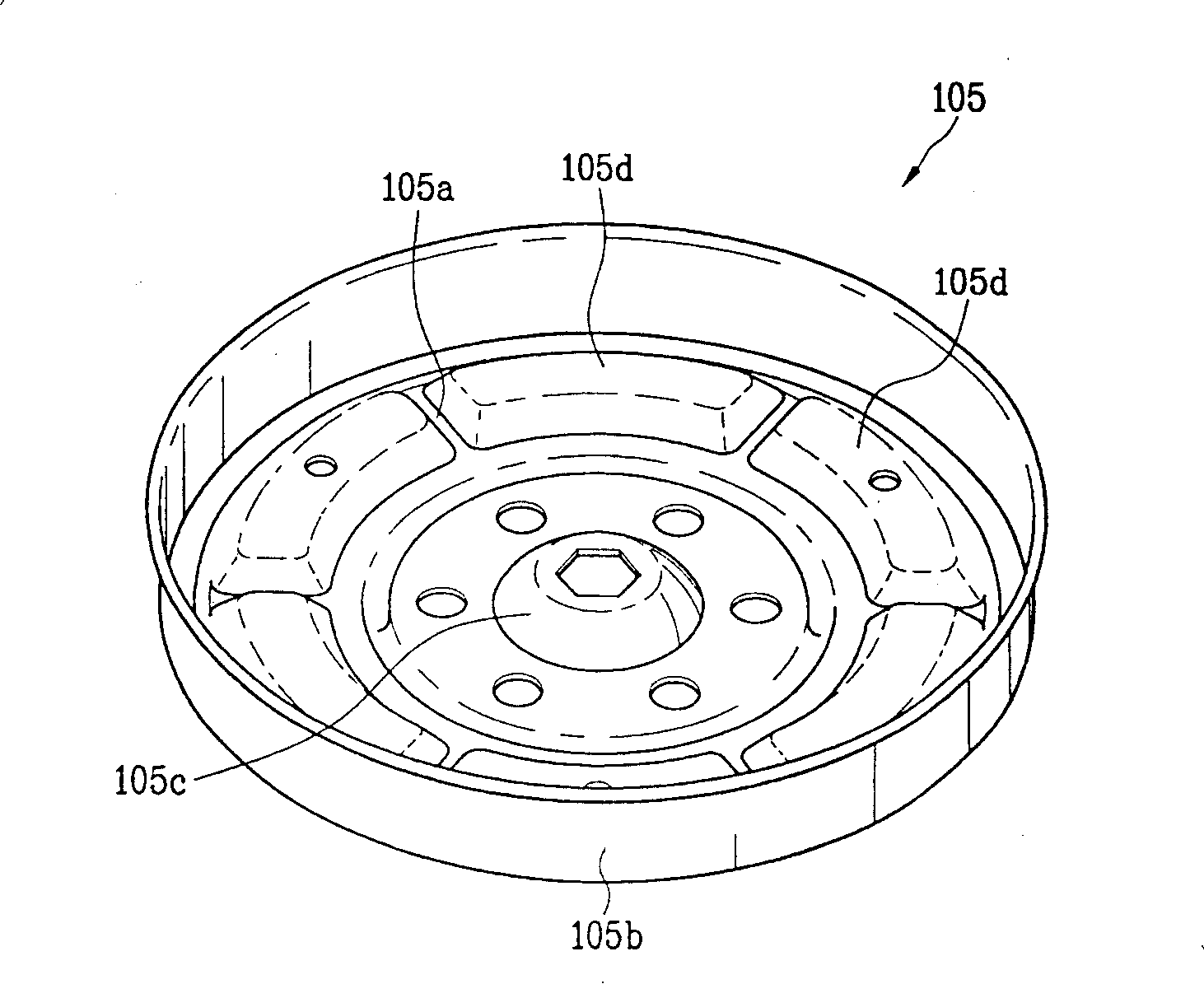

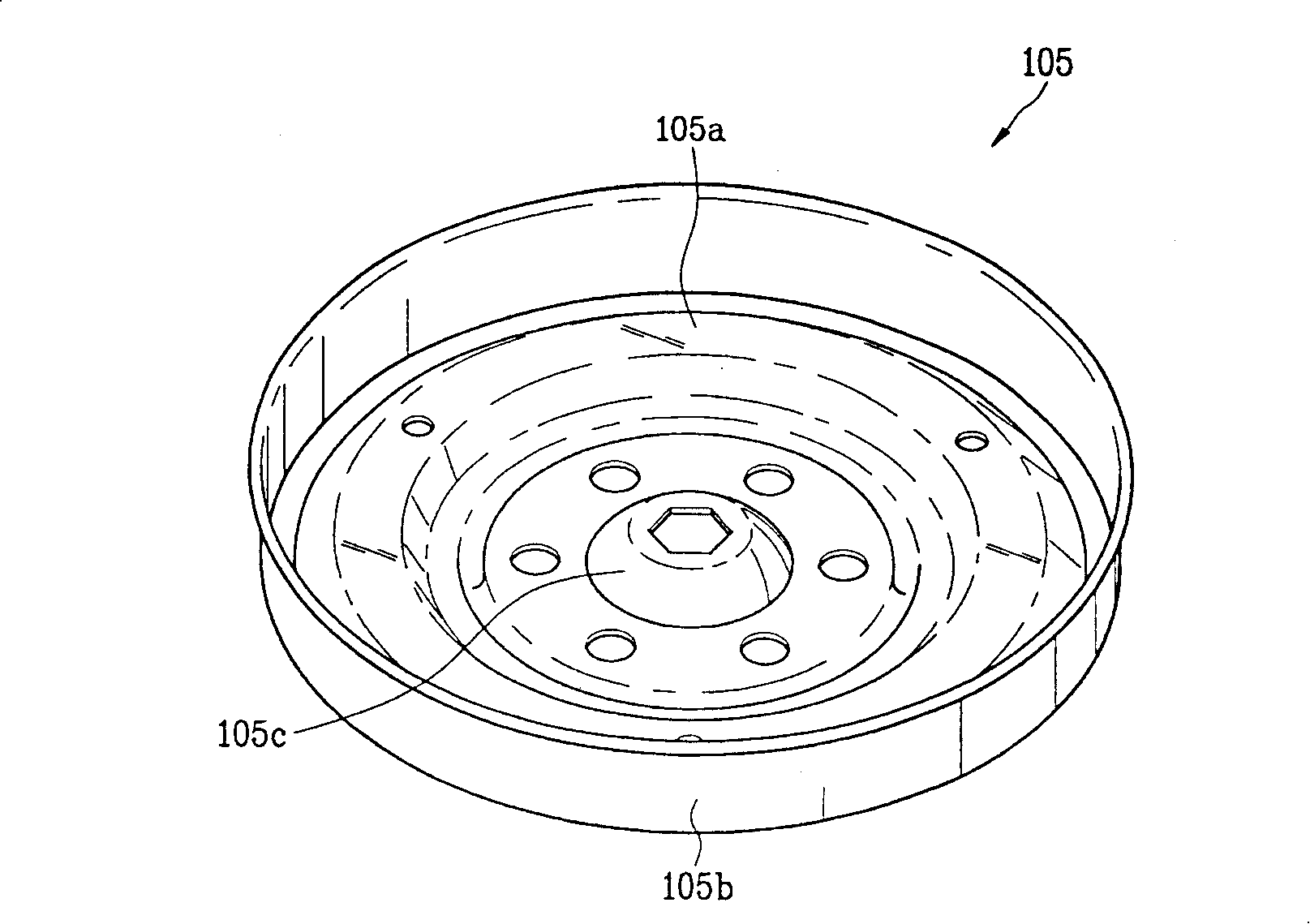

[0035] Refer below image 3 , Figure 4 , an embodiment of the pulley of the drum washing machine of the present invention will be described in detail.

[0036] image 3 An oblique view of the pulley of the present invention is shown. Figure 4 yes image 3 oblique view of the back.

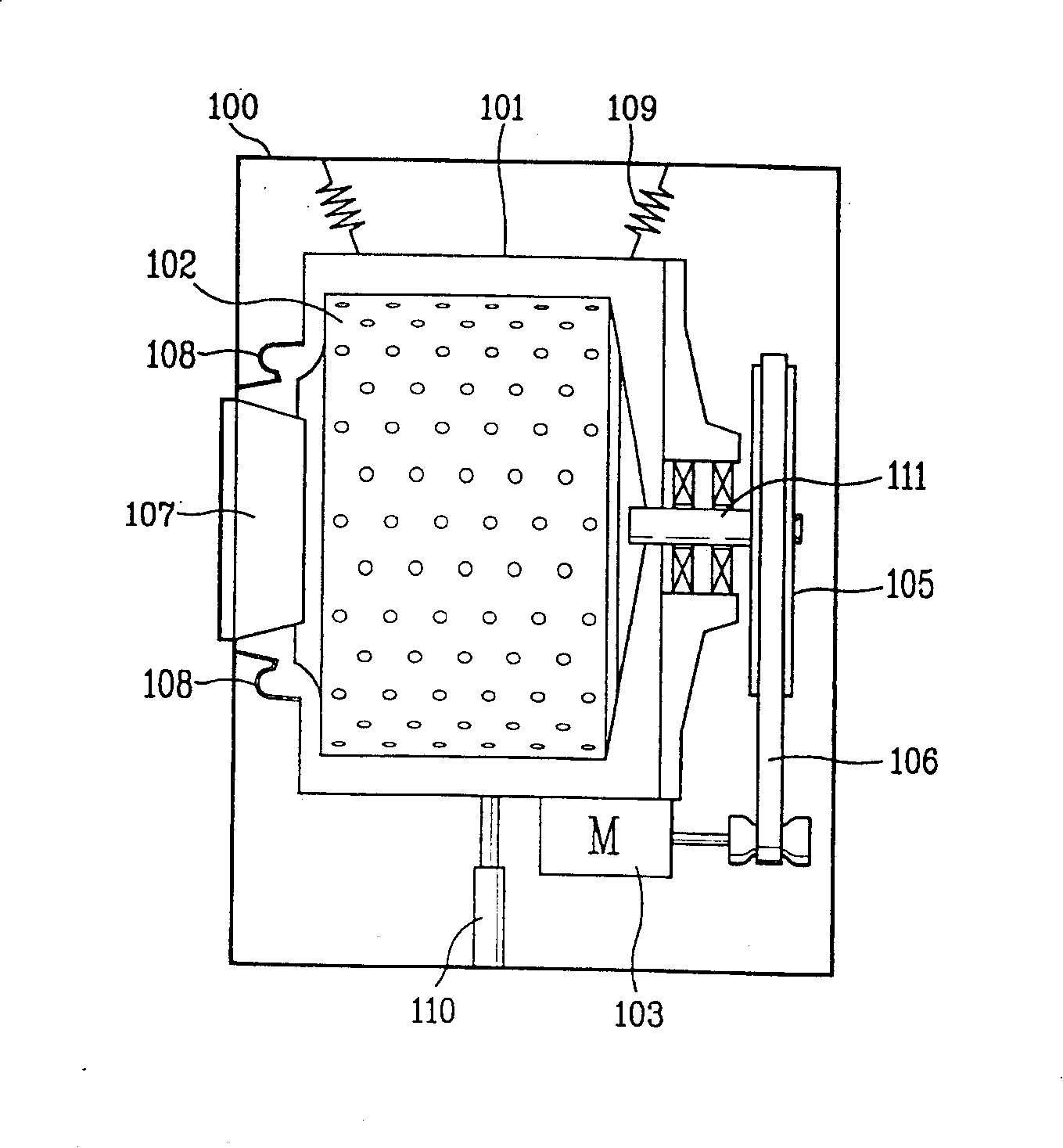

[0037] As shown in the figure, the drum washing machine of the present invention includes the following structures: a body 100 , a washing tank 101 , a motor 103 , a drum 2 , a pulley 105 , a suspension spring 109 and a brake 110 .

[0038] The drum washing machine is equipped with the above-mentioned main body 100; the above-mentioned washing tank 101 is arranged inside the above-mentioned main body 100, and a motor bracket is integrally formed on the outer peripheral surface of the above-mentioned washing tank 101; the above-mentioned motor 103 is installed on the motor bracket of the above-mentioned washing tank 101; The drum 2 is rotatably arranged inside the above-mentioned washing tank...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com