A Method of Reducing the Noise of Switched Reluctance Motor Based on Adjusting PWM Carrier Frequency

A switched reluctance motor, carrier frequency technology, applied in AC motor control, motor vibration suppression control, electrical components and other directions, can solve the problems of resonance noise, large noise, etc., to achieve the effect of simple implementation, noise reduction, and overall noise reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The specific method and operation process provided by the present invention will be described in detail below in conjunction with the accompanying drawings and examples.

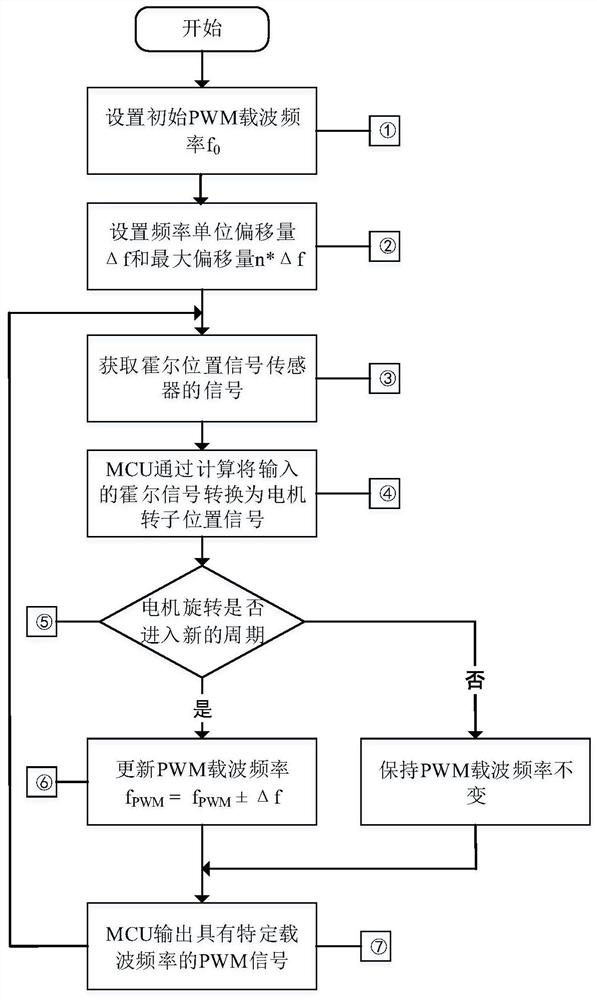

[0026] Operation flowchart of the present invention is as figure 1 As shown, before the switched reluctance motor runs, set the PWM carrier initial frequency f 0 (①), and set the carrier frequency unit offset Δf and the maximum offset n*Δf (②), Δf is the change of the carrier frequency when the motor runs for one cycle, and n*Δf is the PWM carrier The frequency deviates from the fundamental frequency f 0 The maximum offset value of . The microprocessor judges the rotor position signal of the switched reluctance motor through the Hall signal transmitted by the Hall position signal sensor, and converts the Hall signal input into the microprocessor into the motor rotor position signal after calculation (③④), and then according to the actual The mechanical angle corresponding to one cycle of the contro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com