Engine-driven air conditioning machine

An engine-driven, air-conditioning technology, applied in air-conditioning systems, machine operation, refrigerators, etc., can solve the problems of refrigerant quantity regulation, heating capacity decline, and low heat exchange efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Hereinafter, embodiments of the present invention will be described with reference to the drawings.

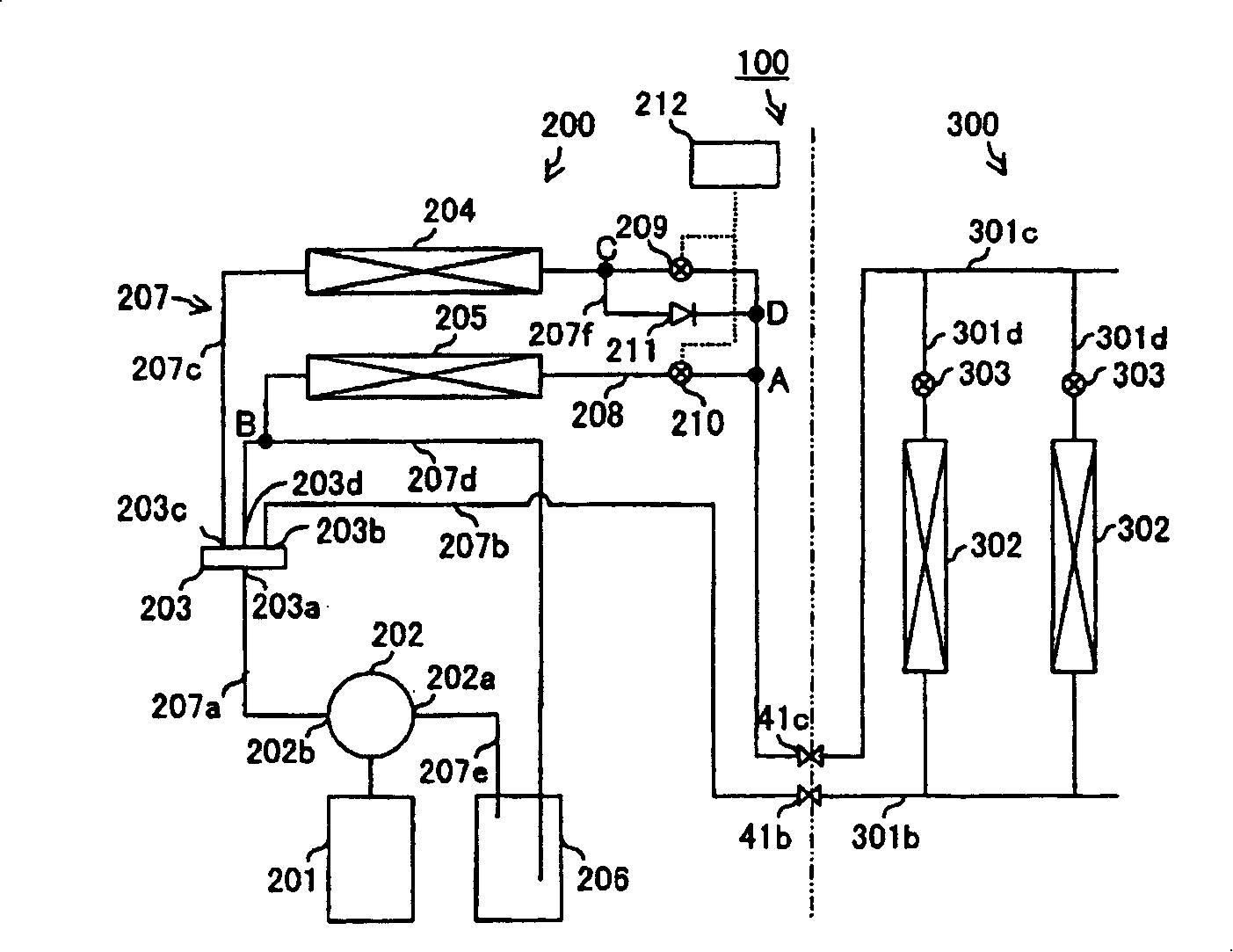

[0029] figure 1 It is a simplified structural diagram of the engine-driven air conditioner in this example. exist figure 1 Among them, the engine-driven air conditioner 100 in this example is roughly divided into an outdoor unit 200 and an indoor unit 300 .

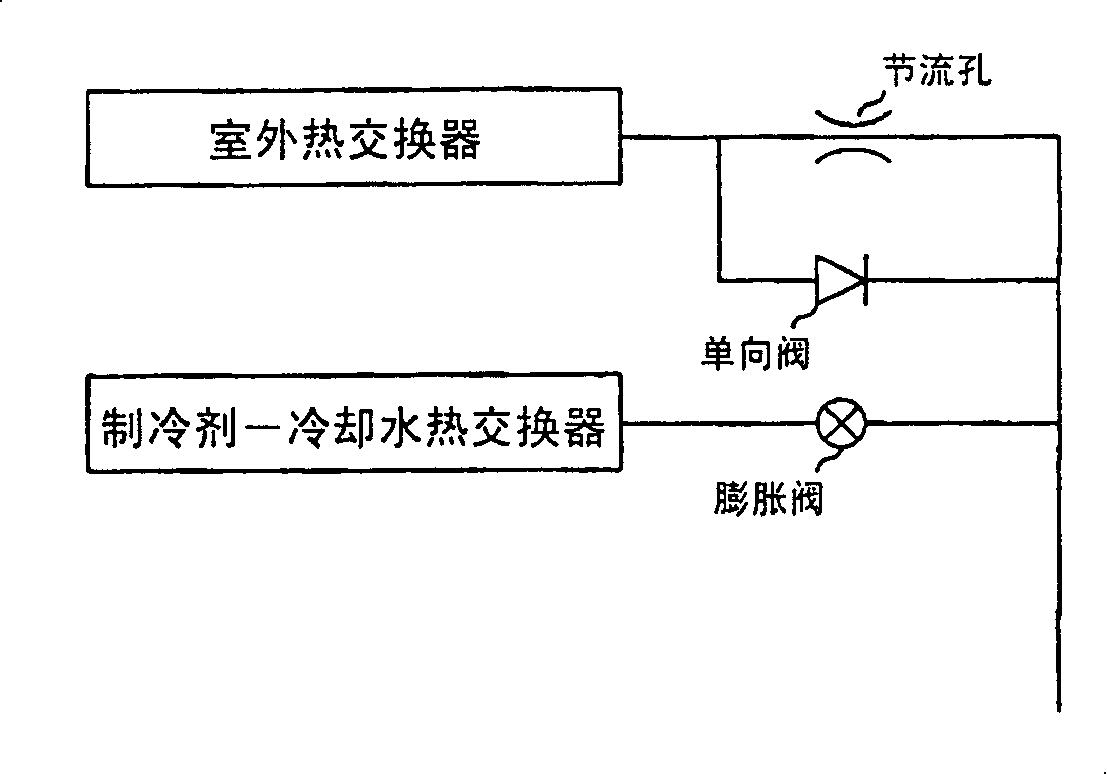

[0030] In the outdoor unit 200, an engine 201, a compressor 202, a four-way switching valve 203, an outdoor heat exchanger 204, a heat accumulator 206, a refrigerant passage 207 connecting these, a refrigerant-cooling water heat exchanger 205, an insert The bypass passage 208 in which the refrigerant-cooling water heat exchanger 205 is installed is a main component, and is housed in a casing (not shown in the figure) of the outdoor unit.

[0031] The engine 201 is a device that functions as a prime mover, and any device may be used, but in an engine-driven air conditioner, a gas engine driven by gaseous fuel is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com