Novel annular seal steel skeleton production method

A manufacturing method and steel frame technology, applied in the field of mechanical processing, can solve the problems of low strength of the steel frame of the sealing ring, complex manufacturing method, and easy damage life, and achieve simple and easy processing technology, low processing cost, and low product price Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

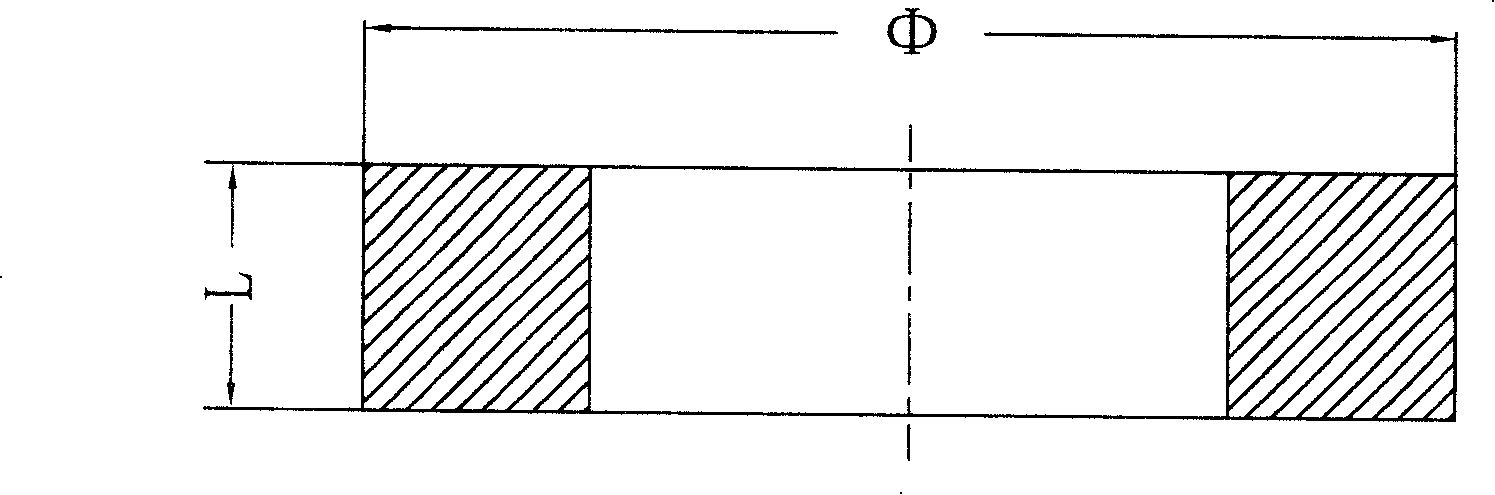

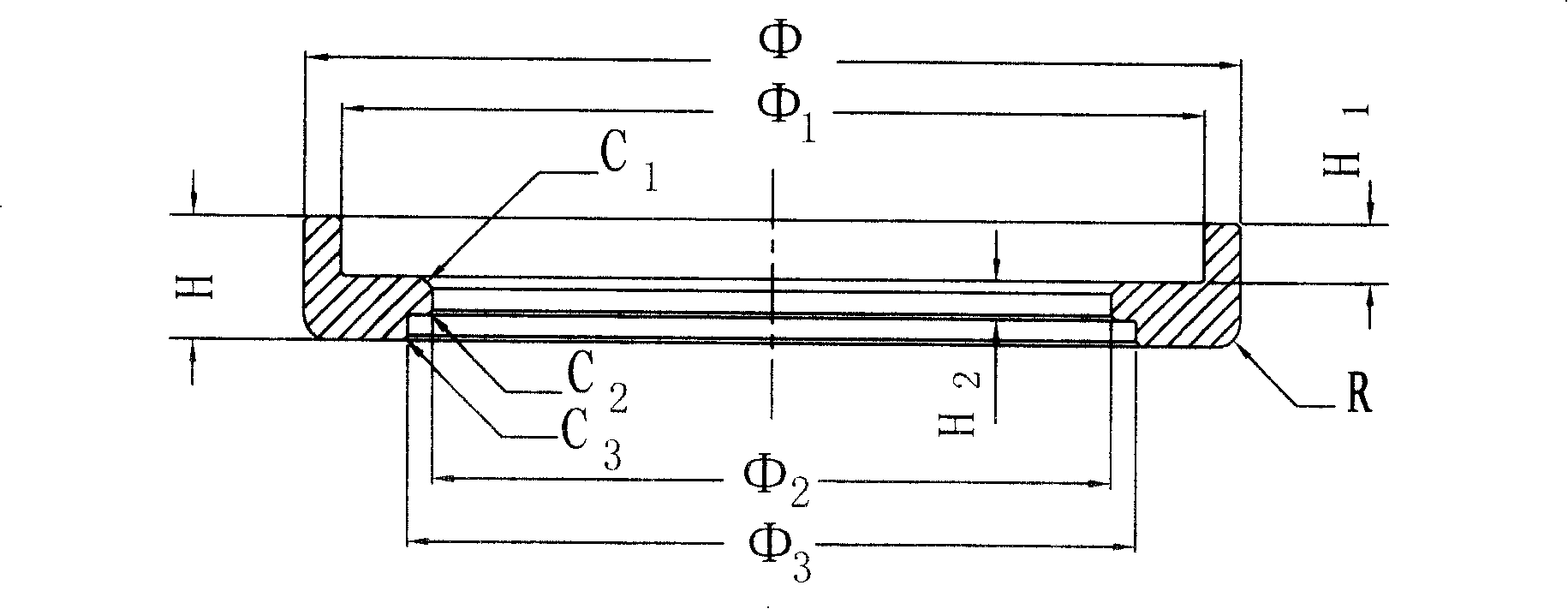

[0033] Such as figure 2 , image 3 Shown, a kind of manufacturing method of new sealing ring steel skeleton is characterized in that it is realized through the following steps:

[0034] (1) Select 45# seamless steel pipe, and cold draw the selected steel pipe through a cold drawing machine so that the outer diameter of the steel pipe meets the design requirements of the steel skeleton of the sealing ring, that is, the outer diameter of the steel skeleton of the sealing ring is Φ=39.9mm, and the steel pipe The inner diameter of the inner diameter is 28.7mm, which includes the machining allowance of the subsequent process;

[0035] (2) Saw and cut the drawn steel pipe on a sawing machine to form a ring-shaped blank. The height of the obtained ring-shaped blank is 6.5mm, and this height contains the machining allowance of the subsequent process;

[0036] (3) putting the ring-shaped blank obtained by cutting into the drum of the roller machine and rolling it, and removing the s...

Embodiment 2

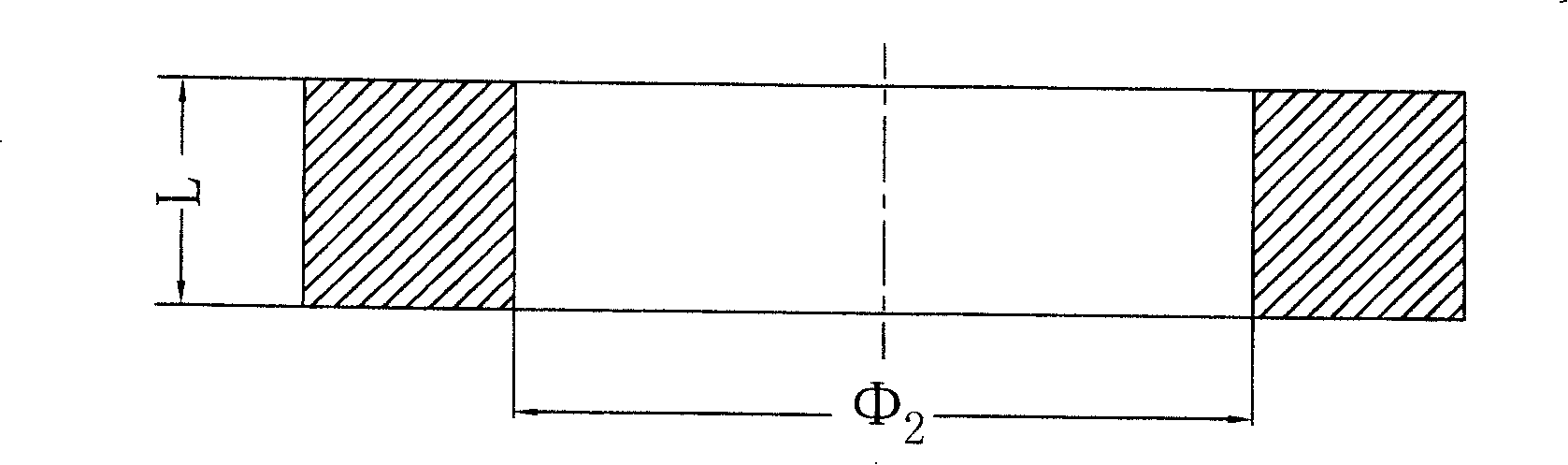

[0043] Such as figure 1 , image 3 Shown, a kind of manufacturing method of new sealing ring steel skeleton is characterized in that it is realized through the following steps:

[0044] (1) Select 40Cr seamless steel pipe, and cold draw the selected steel pipe through a cold drawing machine, so that the inner diameter of the steel pipe meets the design requirements of the steel skeleton of the sealing ring, that is, the inner diameter of the middle part of the steel skeleton of the sealing ring Φ 2 = 27.5mm, the outer diameter of the steel pipe is 38.1mm, and the outer diameter includes the machining allowance of the subsequent process;

[0045] (2) Saw and cut the drawn steel pipe on a sawing machine to form a ring-shaped blank. The height of the obtained ring-shaped blank is 6.5mm, and this height contains the machining allowance of the subsequent process;

[0046] (3) putting the ring-shaped blank obtained by cutting into the drum of the roller machine and rolling it, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com