Method of extracting radioactive uranium in phosphate

A technology for radioactive uranium and phosphate, applied in the field of extracting radioactive uranium, can solve problems such as inability to meet demand and shortage of resources, and achieve the effects of shortening project time, improving radioactive pollution, and reducing costs and risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

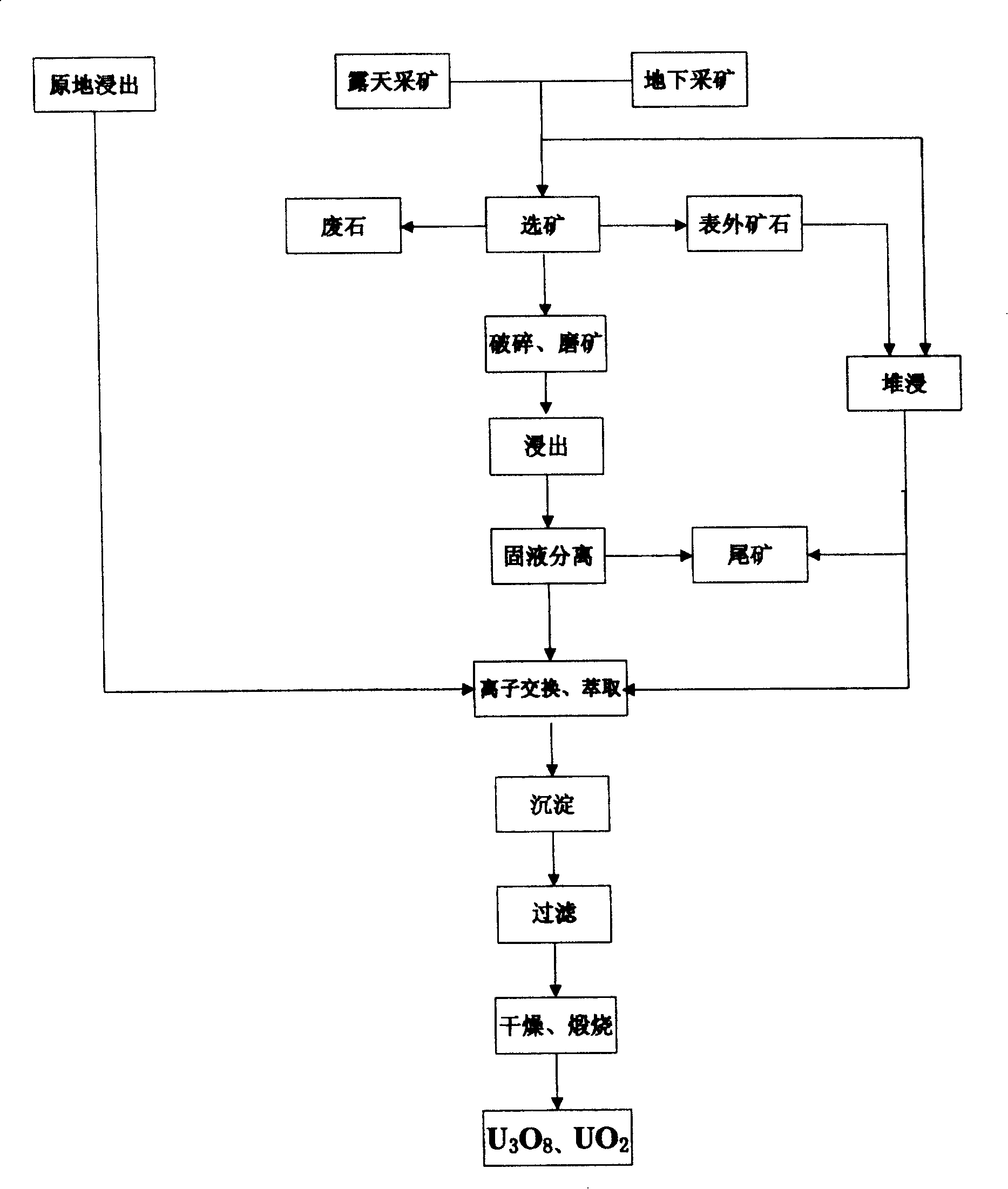

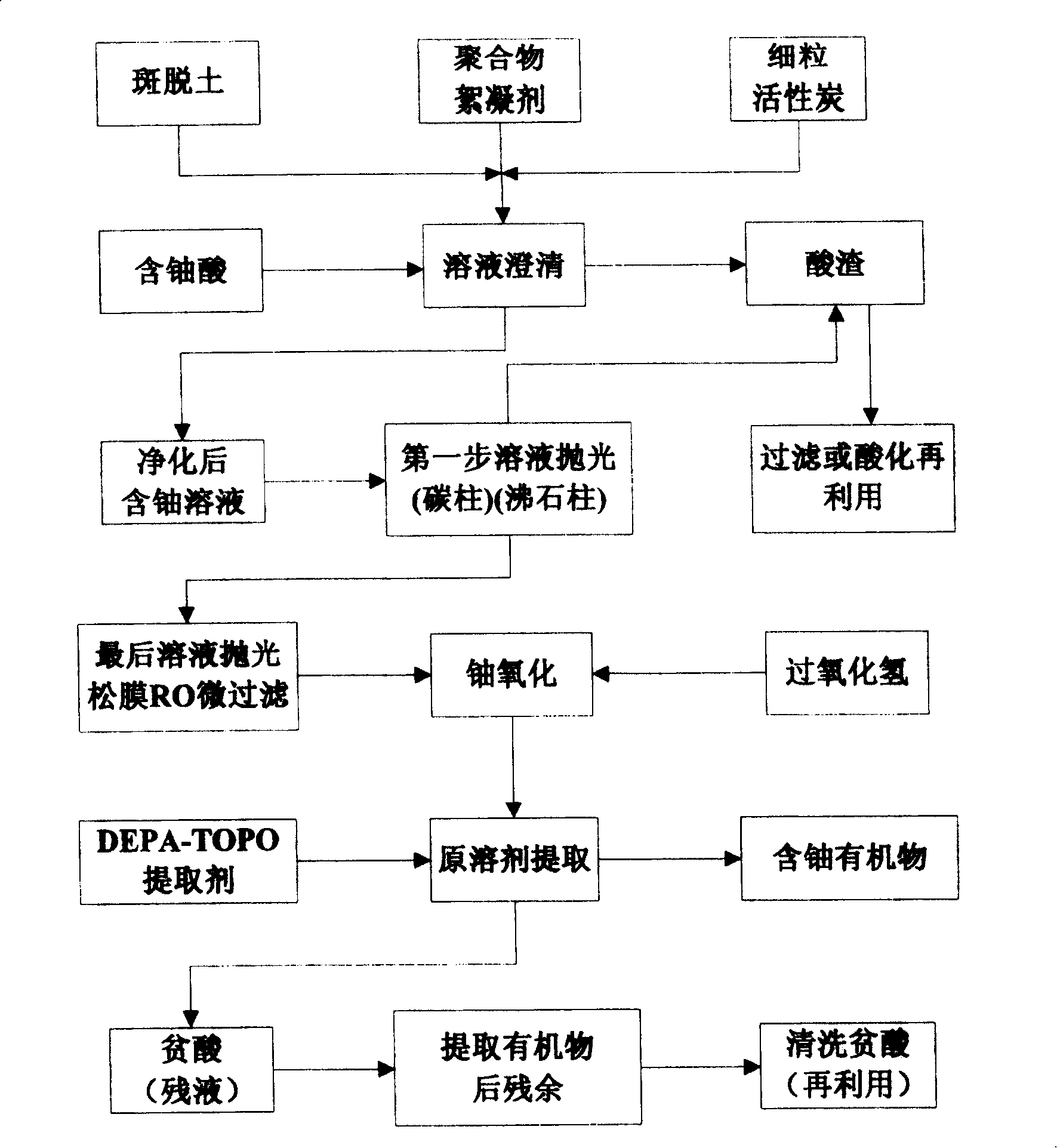

[0042] The method of the present invention will be further described in detail in conjunction with the accompanying drawings and the embodiment of extracting radioactive uranium from phosphate ore.

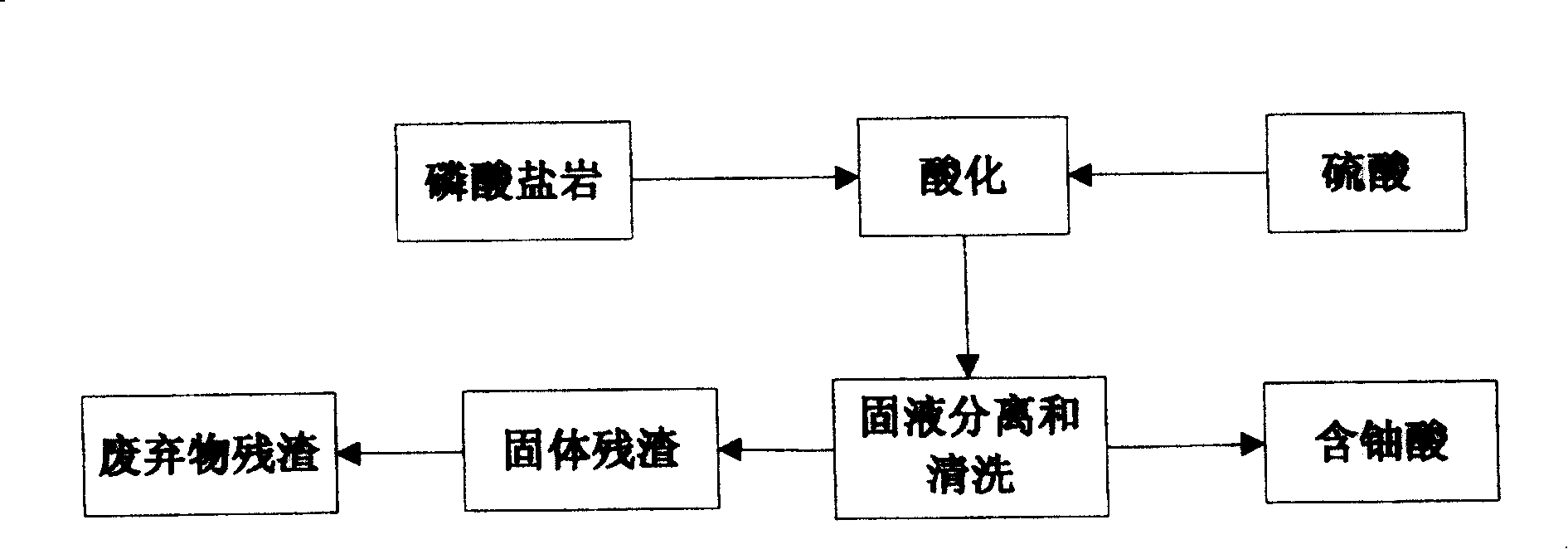

[0043] Usually the main use of phosphate rock is to produce phosphate-containing fertilizers. refer to figure 2 The process of mining and ore processing is firstly carried out to obtain phosphate rock, and then acidified with sulfuric acid to prepare phosphoric acid (usually called wet process phosphoric acid). After solid-liquid separation and cleaning, the uranium-containing acid is separated, and the remaining solid residue is further processed. Phosphate rocks may contain large amounts of uranium, generally in the range of 0.1 to 0.5 pounds per ton, and more commonly in the range of 0.2 to 0.4 pounds per ton. After uranium is dissolved (that is, in wet-process phosphoric acid), the content of uranium in uranium-containing acid is about 0.15g to 0.25g per liter. This acidif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com