Horizontal pumping system and pumping control method for automobile wind tunnel

A suction system and automobile wind tunnel technology, applied in the fields of aerodynamics and vehicle engineering, can solve the problems of reducing the quality of the flow field in the test section, easily generating airflow deflection angle, and affecting the measurement of aerodynamic force, so as to overcome the static pressure of the test section Effect of Gradient or Airflow Angle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

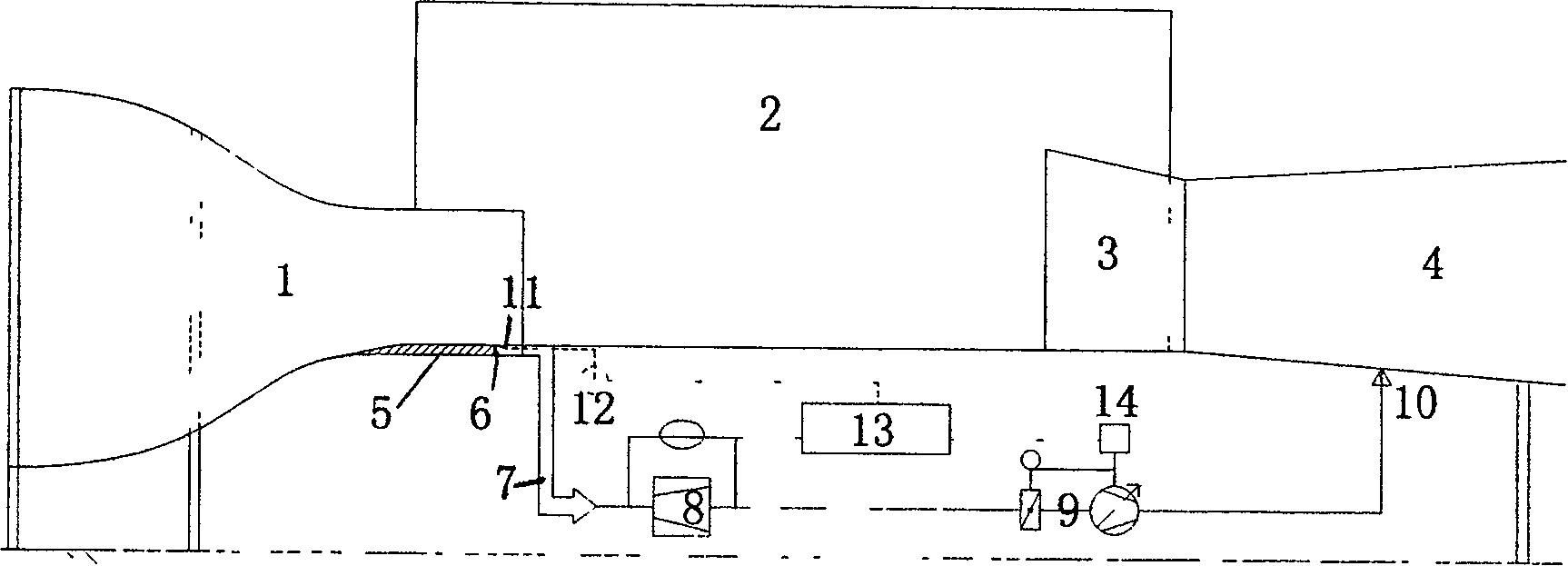

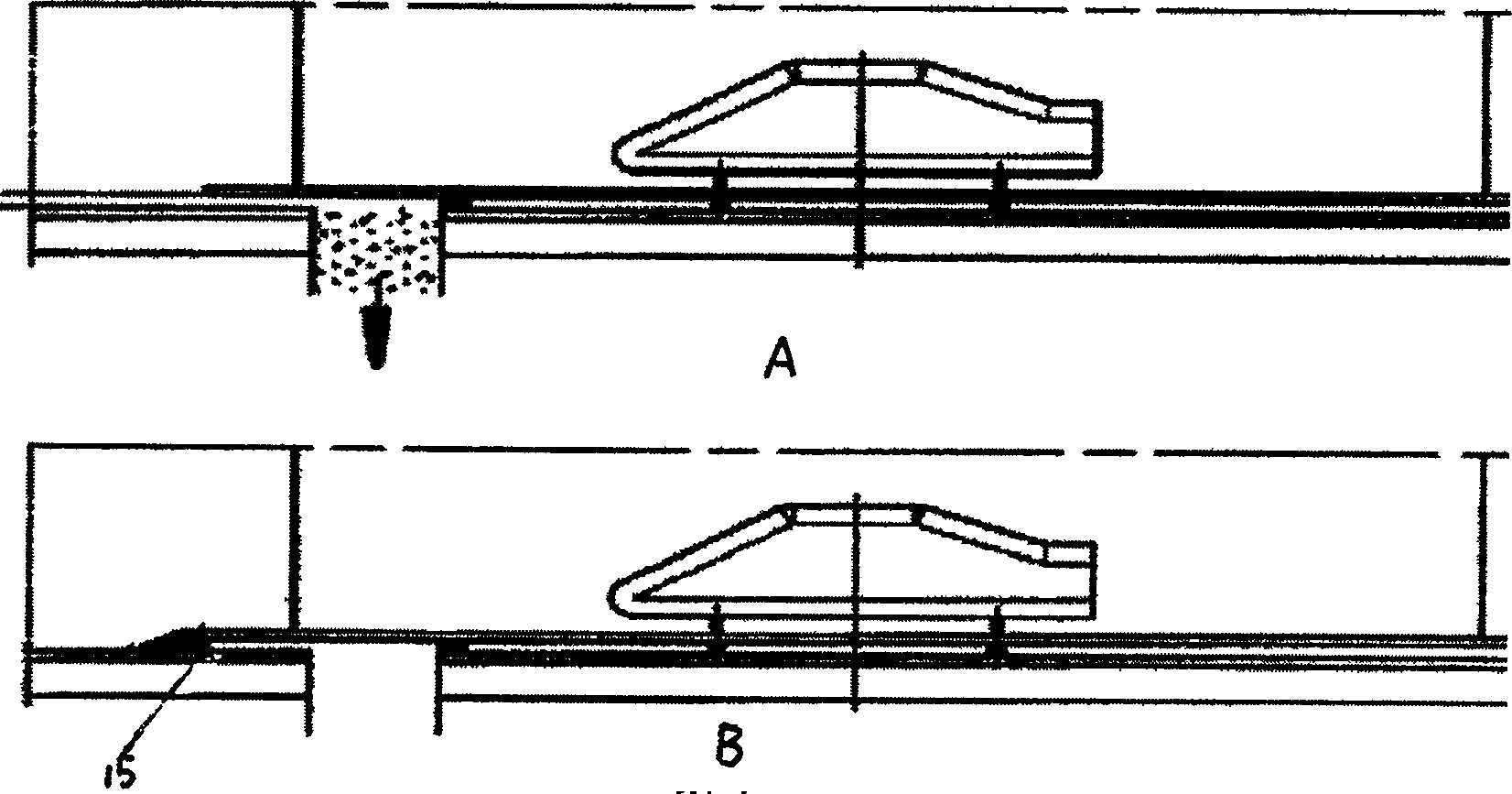

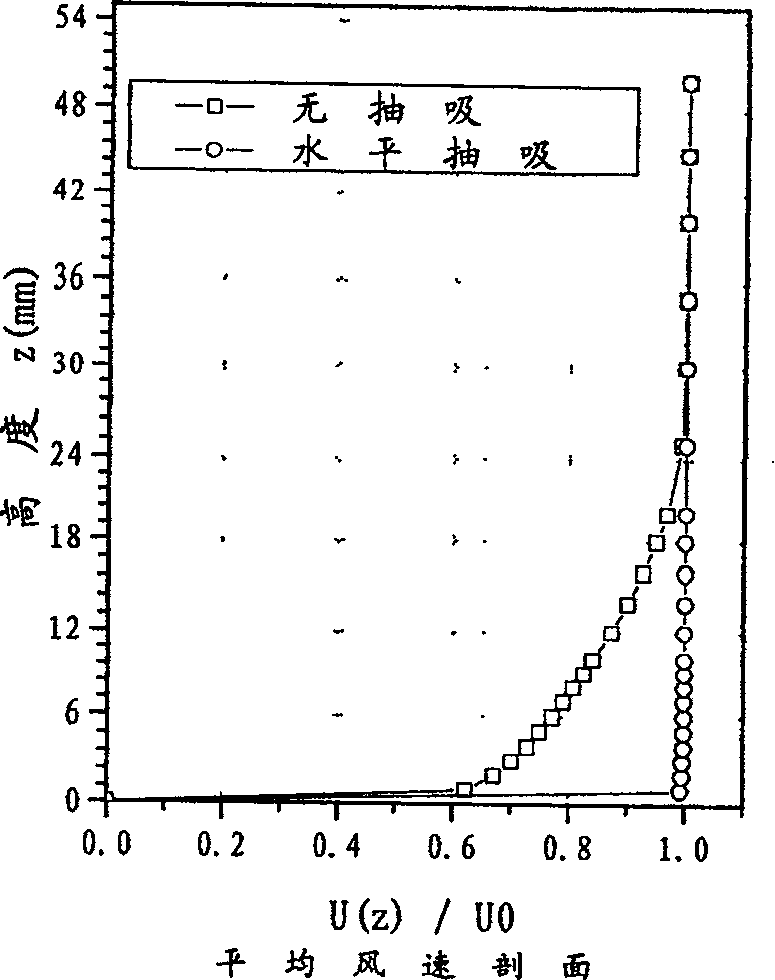

[0036] Press the following parts to figure 1 The manner shown can be successfully implemented by those skilled in the art. A horizontal suction groove 6 is arranged below the exit of the nozzle 1 of the wind tunnel to form a suction port 15, and the suction port 15 extends L into the nozzle. ex =200mm, the maximum height H of the suction port 15 sc =20mm, the front edge of the suction port 15 is connected to the suction port seal 5, the upper and lower ends of the front edge of the suction port 15 are provided with a pressure measuring hole 11, and the pressure measuring hole 11 is connected to the differential pressure sensor 12 through a pressure measuring tube; The model of the sensor 12 is 1151DR differential pressure transmitter, one end of the flowmeter 8 is connected to the suction port 15 through the suction air flow pipe 7, and the other end is connected to the suction fan 9 through the pipe, and the model of the flowmeter 8 is LGW standard Venturi Tube type, the mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com