Method for preparing detector in ultraviolet light

A detector and ultraviolet light technology, which is applied in semiconductor devices, final product manufacturing, sustainable manufacturing/processing, etc., can solve the problem of not having the excellent performance of natural single crystal diamond, which is not conducive to surface photolithography electrodes and signal extraction, and diamond film Surface flatness is not high, to achieve the effect of reducing carrier recombination, improving charge collection efficiency, and less grain boundaries

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

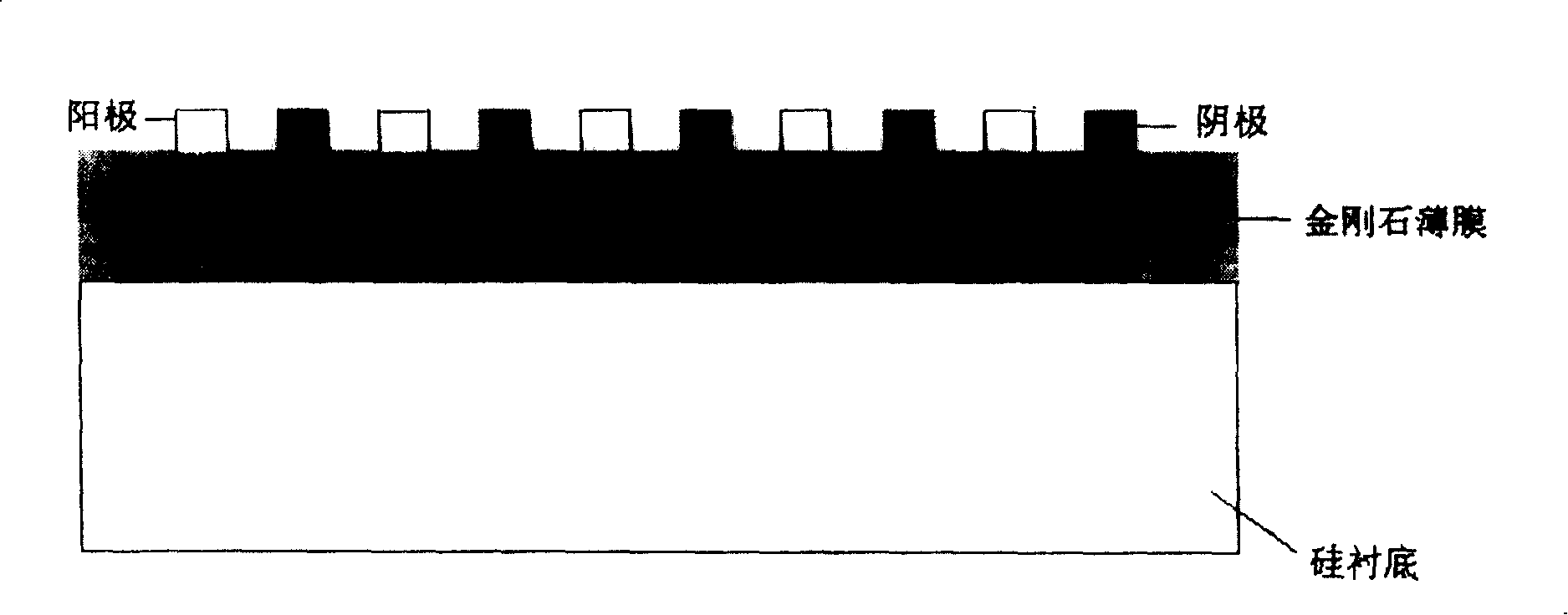

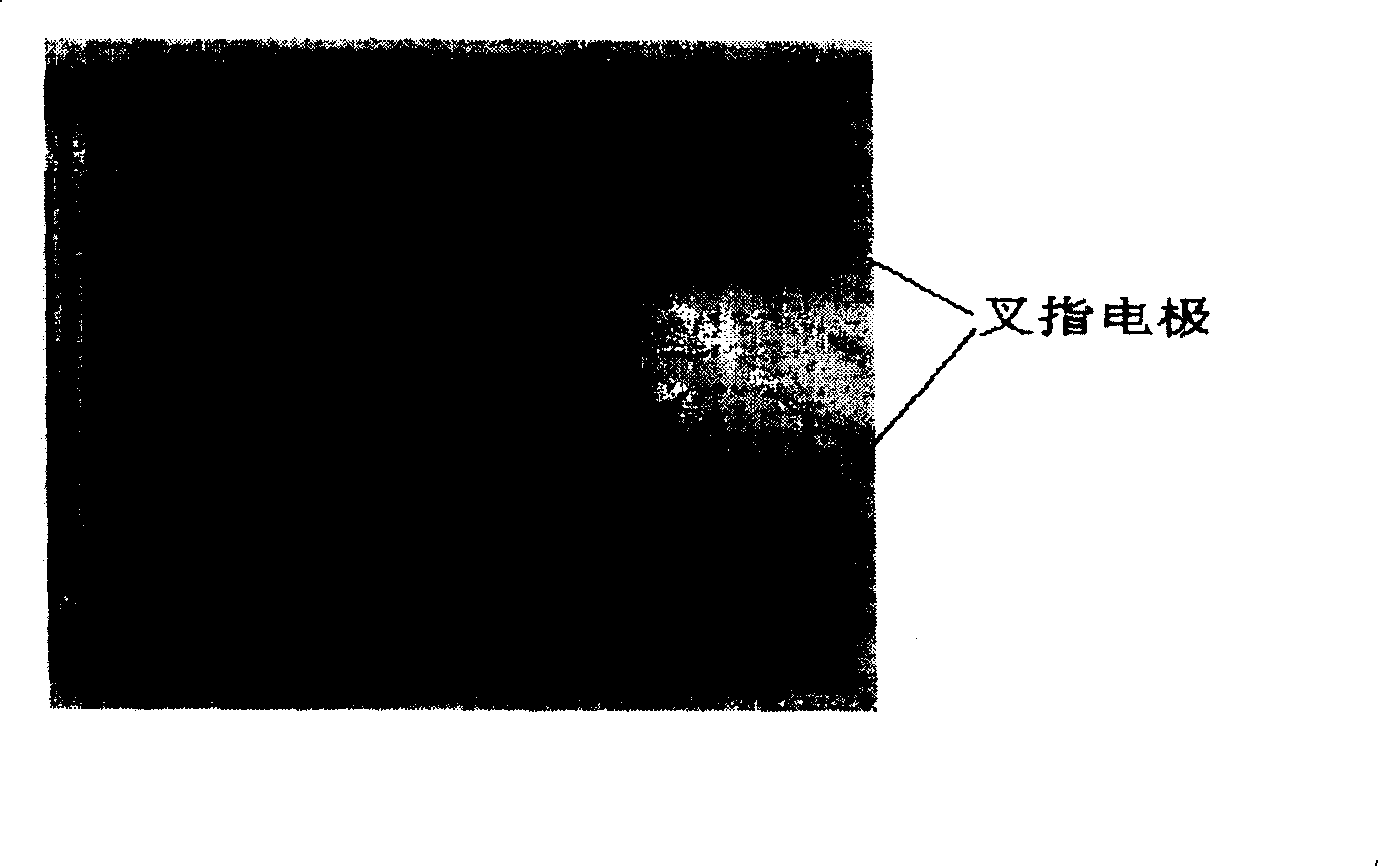

[0020] Example 1, see figure 1 , 2 , the specific process steps of the present embodiment are as follows:

[0021] (1) Substrate pretreatment: use an area of 1×1cm 2 A (100) silicon wafer was used as a substrate, and was ultrasonically cleaned with HF acid for 10 minutes to remove the silicon oxide layer on the surface. Use diamond powder with a particle size of 100nm to perform mechanical grinding for 5 minutes to produce uniform scratches on the entire silicon substrate surface. At the same time, many diamond particles have been embedded on the silicon substrate. These scratches and diamond particles are formed during the nucleation period. Become the original nucleation center, greatly increasing the nucleation density of diamond. The ground silicon wafers were ultrasonically cleaned with deionized water and acetone for 10 minutes respectively to remove impurities and organic matter on the surface, dried and placed in a hot wire deposition reaction chamber.

[0022] (...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com